AG/SAG Mill (Variable Rates): Difference between revisions

imported>Scott.Munro m (→See also) |

imported>Scott.Munro m (→See also) |

||

| Line 56: | Line 56: | ||

* <math>D_{\rm L}</math> is the discharge rate of liquids from the mill, normally assumed to equal <math>D_n</math> (h<sup>-1</sup>). | * <math>D_{\rm L}</math> is the discharge rate of liquids from the mill, normally assumed to equal <math>D_n</math> (h<sup>-1</sup>). | ||

</hide><div class="user-show"> | |||

=== Calculation sequence === | === Calculation sequence === | ||

</div><hide> | |||

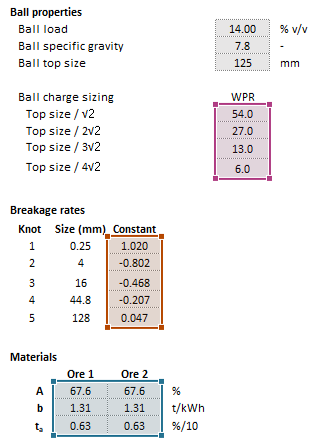

The Variable Rates AG/SAG model uses a range of sub-models to quantify the breakage rate (<math>R</math>), appearance function (<math>A</math>), and discharge function (<math>D</math>) terms of the perfect mixing model, and hence compute the mill load (<math>s</math>) and product (<math>p</math>) at steady-state. | The Variable Rates AG/SAG model uses a range of sub-models to quantify the breakage rate (<math>R</math>), appearance function (<math>A</math>), and discharge function (<math>D</math>) terms of the perfect mixing model, and hence compute the mill load (<math>s</math>) and product (<math>p</math>) at steady-state. | ||

| Line 64: | Line 66: | ||

The sub-models are described in further detail below. | The sub-models are described in further detail below. | ||

</hide><div class="user-show"> | |||

=== Breakage rates === | === Breakage rates === | ||

</div><hide> | |||

[[File:AGSAGVariableRates12.png|thumb|450px|Figure 4. Breakage rate distribution characterised by cubic spline interpolation.]] | [[File:AGSAGVariableRates12.png|thumb|450px|Figure 4. Breakage rate distribution characterised by cubic spline interpolation.]] | ||

| Line 130: | Line 134: | ||

Figure 4 presents an example breakage rate distribution constructed from the five breakage rate knots and a continuous cubic spline. | Figure 4 presents an example breakage rate distribution constructed from the five breakage rate knots and a continuous cubic spline. | ||

</hide><div class="user-show"> | |||

=== Discharge rates === | === Discharge rates === | ||

</div><hide> | |||

The discharge rates (<math>D</math>) are related to the hold-up of slurry in the mill and particle classification at the discharge grates. | The discharge rates (<math>D</math>) are related to the hold-up of slurry in the mill and particle classification at the discharge grates. | ||

</hide><div class="user-show"> | |||

==== Slurry hold-up ==== | ==== Slurry hold-up ==== | ||

</div><hide> | |||

[[File:AGSAGVariableRates9.png|thumb|450px|Figure 5. Principal dimensions of an AG/SAG mill.]] | [[File:AGSAGVariableRates9.png|thumb|450px|Figure 5. Principal dimensions of an AG/SAG mill.]] | ||

| Line 182: | Line 190: | ||

* <math>r_{\rm m}</math> is the radius of the mill inside the liners (m) | * <math>r_{\rm m}</math> is the radius of the mill inside the liners (m) | ||

In addition to fine slurry, particles up to | In addition to fine slurry, particles up to the grate aperture size will also discharge from the mill. To estimate total discharge flow rate, <math>Q</math> (m<sup>3</sup>/h), Morrell and Stephenson (1996) suggest the following correction:{{Morrell and Stephenson (1996)}} | ||

:<math>Q = k_{\rm g} Q_{\rm m}</math> | :<math>Q = k_{\rm g} Q_{\rm m}</math> | ||

| Line 218: | Line 226: | ||

Thus, slurry hold-up, <math>L_{\rm V}</math>, can be computed for a given feed/discharge flow rate, grate design and mill. | Thus, slurry hold-up, <math>L_{\rm V}</math>, can be computed for a given feed/discharge flow rate, grate design and mill. | ||

</hide><div class="user-show"> | |||

==== Classification and discharge ==== | ==== Classification and discharge ==== | ||

</div><hide> | |||

[[File:AGSAGVariableRates10.png|thumb|450px|Figure 6. Classification function, <math>C_i</math>, with pebble port open are fraction, <math>f_p</math>, specified.]] | [[File:AGSAGVariableRates10.png|thumb|450px|Figure 6. Classification function, <math>C_i</math>, with pebble port open are fraction, <math>f_p</math>, specified.]] | ||

| Line 252: | Line 262: | ||

The value of <math>d_{\rm max}</math> is adjusted during the calculation sequence (Figure 3) to ensure the fraction of solids less than <math>x_{\rm g}</math> plus water retained in the mill load computed by the perfect mixing population balance matches the slurry hold-up determined by the [[AG/SAG Mill (Variable Rates)#Slurry_flow|slurry flow]] calculations. | The value of <math>d_{\rm max}</math> is adjusted during the calculation sequence (Figure 3) to ensure the fraction of solids less than <math>x_{\rm g}</math> plus water retained in the mill load computed by the perfect mixing population balance matches the slurry hold-up determined by the [[AG/SAG Mill (Variable Rates)#Slurry_flow|slurry flow]] calculations. | ||

</hide><div class="user-show"> | |||

=== Appearance function === | === Appearance function === | ||

</div><hide> | |||

The appearance function, <math>A</math>, is defined as the mass-by-size distribution of progeny particles resulting from the breakage of parent particles. | The appearance function, <math>A</math>, is defined as the mass-by-size distribution of progeny particles resulting from the breakage of parent particles. | ||

Two types of particle breakage are theorised to | Two types of particle breakage are theorised to occur within AG/SAG mills: | ||

# ''High energy'' breakage from the impact of cataracting balls and large rocks at the toe of the charge, and | # ''High energy'' breakage from the impact of cataracting balls and large rocks at the toe of the charge, and | ||

| Line 265: | Line 277: | ||

An appearance function is a lower triangular matrix as all broken particles are, by definition, smaller than their parent particle. | An appearance function is a lower triangular matrix as all broken particles are, by definition, smaller than their parent particle. | ||

</hide><div class="user-show"> | |||

==== High energy ==== | ==== High energy ==== | ||

</div><hide> | |||

Leung et al. (1987) related the amount of energy available for high energy impact breakage in a mill to the mean size of the top 20% of the charge, <math>S_{20}</math> (mm). The <math>S_{20}</math> is defined as:{{Leung et al. (1987)}} | Leung et al. (1987) related the amount of energy available for high energy impact breakage in a mill to the mean size of the top 20% of the charge, <math>S_{20}</math> (mm). The <math>S_{20}</math> is defined as:{{Leung et al. (1987)}} | ||

| Line 349: | Line 363: | ||

The [[Crusher (Whiten)|Whiten crusher]] model also applies a similar appearance function spline interpolation procedure. | The [[Crusher (Whiten)|Whiten crusher]] model also applies a similar appearance function spline interpolation procedure. | ||

</hide><div class="user-show"> | |||

==== Ball load ==== | ==== Ball load ==== | ||

</div><hide> | |||

Semi-Autogenous (SAG) mills add steel ball grinding media to the ore charge to increase size reduction. | Semi-Autogenous (SAG) mills add steel ball grinding media to the ore charge to increase size reduction. | ||

| Line 384: | Line 400: | ||

# Combine the ball volume-by-size and ore volume-by-size in the charge (<math>s_i</math>) when computing the <math>S_{20}</math>. | # Combine the ball volume-by-size and ore volume-by-size in the charge (<math>s_i</math>) when computing the <math>S_{20}</math>. | ||

</hide><div class="user-show"> | |||

==== Low energy ==== | ==== Low energy ==== | ||

</div><hide> | |||

The low energy appearance function is computed from the ore-specific abrasion parameter, <math>t_a</math> (%), which is obtained from the ore abrasion test described by Napier-Munn et al. (1996).{{Napier-Munn et al. (1996)}} | The low energy appearance function is computed from the ore-specific abrasion parameter, <math>t_a</math> (%), which is obtained from the ore abrasion test described by Napier-Munn et al. (1996).{{Napier-Munn et al. (1996)}} | ||

| Line 414: | Line 432: | ||

Note that a [[Interpolation#Cubic_spline_interpolation|monotonic spline]] is employed for the low energy appearance function as the sharp change in cumulative fraction passing values between the original parent size (<math>t_1</math>) and the first progeny size (<math>t_{1.25}</math>) can result in undesired oscillation and negative function values when applying a regular cubic spline. | Note that a [[Interpolation#Cubic_spline_interpolation|monotonic spline]] is employed for the low energy appearance function as the sharp change in cumulative fraction passing values between the original parent size (<math>t_1</math>) and the first progeny size (<math>t_{1.25}</math>) can result in undesired oscillation and negative function values when applying a regular cubic spline. | ||

</hide><div class="user-show"> | |||

==== Combined appearance function ==== | ==== Combined appearance function ==== | ||

</div><hide> | |||

The high and low energy appearance functions are combined based on the relative proportions of <math>t_{\rm a}</math> and the <math>t_{10}</math> at each specific comminution energy:{{Leung et al. (1987)}} | The high and low energy appearance functions are combined based on the relative proportions of <math>t_{\rm a}</math> and the <math>t_{10}</math> at each specific comminution energy:{{Leung et al. (1987)}} | ||

| Line 420: | Line 440: | ||

:<math>A = \dfrac{t_{10} . A_{\rm HE} + t_{\rm a} . A_{\rm LE}}{t_{10} + t_{\rm a}}</math> | :<math>A = \dfrac{t_{10} . A_{\rm HE} + t_{\rm a} . A_{\rm LE}}{t_{10} + t_{\rm a}}</math> | ||

</hide><div class="user-show"> | |||

=== Mill power === | === Mill power === | ||

</div><hide> | |||

The Variable Rates AG/SAG model includes an implementation of the [[Tumbling Mill (Power, Morrell Continuum)|Morrell Continuum]] tumbling mill power model. The predicted mill power draw is not utilised by the Variable Rates model formulation in any manner, and is provided for information only. | The Variable Rates AG/SAG model includes an implementation of the [[Tumbling Mill (Power, Morrell Continuum)|Morrell Continuum]] tumbling mill power model. The predicted mill power draw is not utilised by the Variable Rates model formulation in any manner, and is provided for information only. | ||

</hide><div class="user-show"> | |||

==== Charge properties ==== | ==== Charge properties ==== | ||

</div><hide> | |||

The power draw prediction requires an estimate of <math>J_{\rm t}</math> (v/v), the fraction of mill volume occupied by the charge, which includes coarse ore, balls, slurry, and void spaces. | The power draw prediction requires an estimate of <math>J_{\rm t}</math> (v/v), the fraction of mill volume occupied by the charge, which includes coarse ore, balls, slurry, and void spaces. | ||

| Line 459: | Line 483: | ||

:<math>\rho_{\rm c} = \frac{J_{\rm t} \rho_{\rm S} (1 - \varepsilon + \varepsilon U S) + J_{\rm B}( \rho_{\rm B} - \rho_{\rm S})(1 - \varepsilon) + J_{\rm t} \varepsilon U (1 - S)}{J_{\rm t}}, \quad U \leq 1</math> | :<math>\rho_{\rm c} = \frac{J_{\rm t} \rho_{\rm S} (1 - \varepsilon + \varepsilon U S) + J_{\rm B}( \rho_{\rm B} - \rho_{\rm S})(1 - \varepsilon) + J_{\rm t} \varepsilon U (1 - S)}{J_{\rm t}}, \quad U \leq 1</math> | ||

</hide><div class="user-show"> | |||

==== Power draw ==== | ==== Power draw ==== | ||

</div><hide> | |||

:''Main article'': [[Tumbling Mill (Power, Morrell Continuum)]] | :''Main article'': [[Tumbling Mill (Power, Morrell Continuum)]] | ||

| Line 477: | Line 503: | ||

The complete equations are excluded here for brevity and are available at the article link above. | The complete equations are excluded here for brevity and are available at the article link above. | ||

</hide><div class="user-show"> | |||

=== Internal mesh series === | === Internal mesh series === | ||

</div><hide> | |||

The Variable Rates AG/SAG mill model is formulated internally with a geometric progression of <math>n = 42</math> mesh sizes at <math>\sqrt{2}</math> intervals, i.e. | The Variable Rates AG/SAG mill model is formulated internally with a geometric progression of <math>n = 42</math> mesh sizes at <math>\sqrt{2}</math> intervals, i.e. | ||

| Line 495: | Line 523: | ||

The internal mesh series chosen can have an impact on the calculated value of <math>S_{20}</math> via the <math>P_{100}</math> parameter, which subsequently affects the computed mill load and discharge. As such, the internal mesh top size, <math>d_1</math>, is specified by the user. This ensures consistency when model parameters are transferred from once instance to another. | The internal mesh series chosen can have an impact on the calculated value of <math>S_{20}</math> via the <math>P_{100}</math> parameter, which subsequently affects the computed mill load and discharge. As such, the internal mesh top size, <math>d_1</math>, is specified by the user. This ensures consistency when model parameters are transferred from once instance to another. | ||

</hide><div class="user-show"> | |||

=== Multicomponent modelling === | === Multicomponent modelling === | ||

</div><hide> | |||

Published formulations of the Variable Rates AG/SAG model and its predecessors only consider feeds and loads consisting of a single ore type.{{Leung et al. (1987)}}{{Kojovic et al. (2012)}}{{Bueno et al. (2013)}} | Published formulations of the Variable Rates AG/SAG model and its predecessors only consider feeds and loads consisting of a single ore type.{{Leung et al. (1987)}}{{Kojovic et al. (2012)}}{{Bueno et al. (2013)}} | ||

| Line 515: | Line 545: | ||

The multicomponent formulation reverts to the original single ore approach when only one ore type is present, or each ore type of a multicomponent feed is assigned the same values of <math>\rho_{\rm S}</math>, <math>A</math>, <math>b</math>, and <math>t_{\rm a}</math>. | The multicomponent formulation reverts to the original single ore approach when only one ore type is present, or each ore type of a multicomponent feed is assigned the same values of <math>\rho_{\rm S}</math>, <math>A</math>, <math>b</math>, and <math>t_{\rm a}</math>. | ||

</hide><div class="user-show"> | |||

=== Additional notes === | === Additional notes === | ||

</div><hide> | |||

</hide><div class="user-show"> | |||

==== Breakage rates and mill load ==== | ==== Breakage rates and mill load ==== | ||

</div><hide> | |||

An important, and potentially overlooked, limitation of the Variable Rates AG/SAG mill model is the insensitivity of the breakage rate relationships to mill load. Mill simulations should therefore use mill loads close or equal to the load observed during model fitting, or 25% for design activities.{{Bailey et al. (2009)}} | An important, and potentially overlooked, limitation of the Variable Rates AG/SAG mill model is the insensitivity of the breakage rate relationships to mill load. Mill simulations should therefore use mill loads close or equal to the load observed during model fitting, or 25% for design activities.{{Bailey et al. (2009)}} | ||

</hide><div class="user-show"> | |||

==== Slurry pool ==== | ==== Slurry pool ==== | ||

</div><hide> | |||

Various published descriptions of the Variable Rates AG/SAG mill suggest that slurry pooling phenomena are excluded from slurry hold-up and power draw estimations.{{Morrell and Morrison (1996)}}{{Kojovic et al. (2012)}}{{Bueno et al. (2013)}} | Various published descriptions of the Variable Rates AG/SAG mill suggest that slurry pooling phenomena are excluded from slurry hold-up and power draw estimations.{{Morrell and Morrison (1996)}}{{Kojovic et al. (2012)}}{{Bueno et al. (2013)}} | ||

| Line 1,141: | Line 1,177: | ||

* [[Tumbling Mill (Power, Morrell Continuum)]] | * [[Tumbling Mill (Power, Morrell Continuum)]] | ||

* [[Crusher (Whiten)]] | * [[Crusher (Whiten)]] | ||

* [https://help.syscad.net/ | |||

== External links == | |||

* [https://help.syscad.net/Met_Dynamics_-_Mill Met Dynamics - Mill (help.syscad.net)] | |||

* [https://help.syscad.net/Example_-_09_Met_Dynamics_Projects#Crushing_and_Grinding_Example Crushing and Grinding Example project (help.syscad.net)] | |||

== References == | == References == | ||

Revision as of 13:27, 1 May 2025

Description

This article describes an implementation of the Autogenous (AG) and Semi-Autogenous (SAG) mill model originated by Leung (1987) and extended with variable breakage rates by Morrell and Morrison (1996).[1][2][3]

The formulation is referred to in the associated literature as the "Variable Rates" model (Morrell et al., 2001).[4]

Model theory

Calculation sequence

Breakage rates

Discharge rates

Slurry hold-up

Classification and discharge

Appearance function

High energy

Ball load

Low energy

Combined appearance function

Mill power

Charge properties

Power draw

Internal mesh series

Multicomponent modelling

Additional notes

Breakage rates and mill load

Slurry pool

Excel

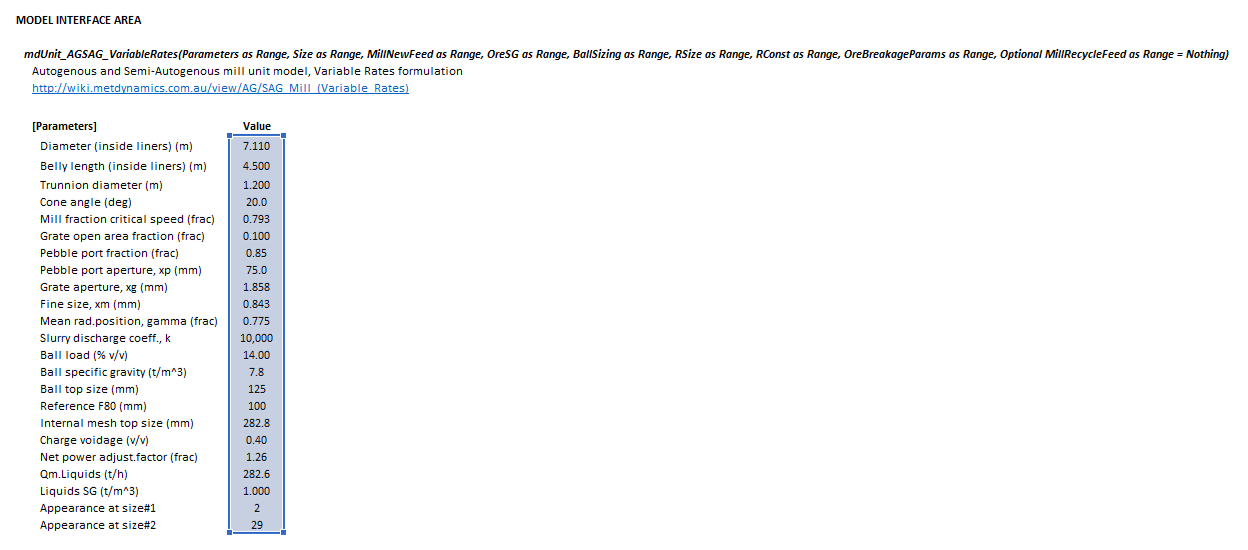

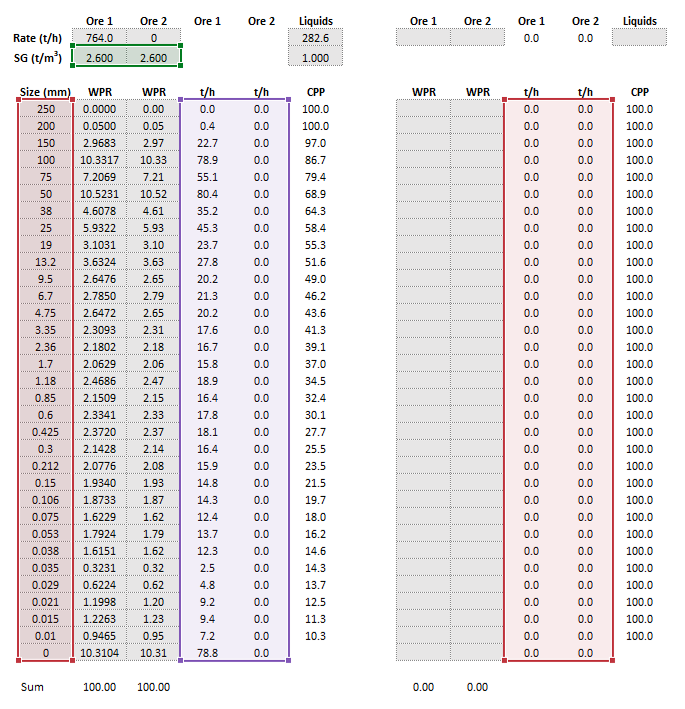

The Variable Rates AG/SAG mill model may be invoked from the Excel formula bar with the following function call:

=mdUnit_AGSAG_VariableRates(Parameters as Range, Size as Range, MillNewFeed as Range, OreSG as Range, BallSizing as Range, RConst as Range, OreBreakageParams as Range, Optional MillRecycleFeed as Range = Nothing)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

Inputs

The required inputs are defined below in matrix notation with elements corresponding to cells in Excel row ([math]\displaystyle{ i }[/math]) x column ([math]\displaystyle{ j }[/math]) format:

- [math]\displaystyle{ \mathit{Parameters} = \begin{bmatrix} D\text{ (m)}\\ L\text{ (m)}\\ D_{\rm t}\text{ (m)}\\ \alpha_{c}\text{ (deg.)}\\ \phi\text{ (frac)}\\ A_{\rm OF}\text{ (m}^{\text{2}}\text{)}\\ f_{\rm p}\text{ (m}^2\text{/m}^2\text{)}\\ x_{\rm p}\text{ (mm)}\\ x_{\rm g}\text{ (mm)}\\ x_{\rm m}\text{ (mm)}\\ \gamma\text{ (m/m)}\\ k\text{ (-)}\\ J_{\rm B}\text{ (v/v)}\\ \rho_{\rm B}\text{ (t/m}^3\text{)}\\ d_{\rm B,Top}\text{ (mm)}\\ F_{80}\text{ (mm)}\\ d_1\text{ (mm)}\\ \varepsilon\text{ (v/v)}\\ (Q_{\rm M,F})_{\rm L}\text{ (t/h)}\\ \rho_{\rm L}\text{ (t/m}^{\text{3}}\text{)}\\ u\\ v\\ \end{bmatrix},\;\;\;\;\;\; \mathit{Size} = \begin{bmatrix} \hat{d}_{1}\text{ (mm)}\\ \vdots\\ \hat{d}_r\text{ (mm)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{MillNewFeed} = \begin{bmatrix} (Q_{\rm M,F})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,F})_{r1}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{rm}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{OreSG} = \begin{bmatrix} (\rho_{\rm S})_{1}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_m\text{ (t/m}^\text{3}\text{)}\\ \end{bmatrix},\;\;\;\;\;\; }[/math]

- [math]\displaystyle{ \mathit{BallSizing} = \begin{bmatrix} (d_{\rm B})_1 \text{ (mm)} & (\mathit{MF}_{\rm B})_1\text{ (}%\text{ w/w)}\\ \vdots& \vdots\\ (d_{\rm B})_s \text{ (mm)} & (\mathit{MF}_{\rm B})_s\text{ (}%\text{ w/w)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{RConst} = \begin{bmatrix} \mathit{RConst}_1 \text{ (} \ln \rm h^{-1} \text{)}\\ \vdots\\ \mathit{RConst}_5 \text{ (} \ln \rm h^{-1} \text{)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{OreBreakageParams} = \begin{bmatrix} A_1\text{ (}%\text{ w/w)} & \dots & A_m\text{ (}%\text{ w/w)}\\ b_1 & \dots & b_m\\ (t_{\rm a})_1\text{ (}%\text{ w/w)} & \dots & (t_{\rm a})_m\text{ (}%\text{ w/w)}\\ \end{bmatrix},\quad \mathit{MillRecycleFeed} = \begin{bmatrix} (Q_{\rm M,R})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,R})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,R})_{r1}\text{ (t/h)} & \dots & (Q_{\rm M,R})_{rm}\text{ (t/h)}\\ \end{bmatrix}^* }[/math]

where:

- [math]\displaystyle{ (Q_{\rm M,F})_{\rm L} }[/math] is the mass flow feed rate of liquids into the mill (t/h)

- [math]\displaystyle{ \rho_{\rm L} }[/math] is the Specific Gravity or density of liquids in the feed (- or t/m3)

- [math]\displaystyle{ u }[/math] is an index of the Appearance function to view in the results

- [math]\displaystyle{ v }[/math] is an index of the Appearance function to view in the results

- [math]\displaystyle{ m }[/math] is the number of ore types

- [math]\displaystyle{ r }[/math] is the number of intervals of the external mesh series

- [math]\displaystyle{ s }[/math] is the number of intervals of the ball mesh series below the top size, including the submesh

- [math]\displaystyle{ \hat{d}_i }[/math] is the size of the external square mesh interval that feed mass is retained on (mm)

- [math]\displaystyle{ \hat{d}_{i+1}\lt \hat{d}_i\lt \hat{d}_{i-1} }[/math], i.e. descending size order from top size ([math]\displaystyle{ \hat{d}_{1} }[/math]) to sub mesh ([math]\displaystyle{ \hat{d}_{p}=0 }[/math])

- [math]\displaystyle{ (d_{\rm B})_i }[/math] is the size of the square mesh interval that balls are retained on (mm)

- [math]\displaystyle{ (\mathit{MF}_{\rm B})_i }[/math] is the mass fraction of balls retained on ball mesh series interval [math]\displaystyle{ i }[/math] (% w/w)

- [math]\displaystyle{ ^* }[/math] indicates the [math]\displaystyle{ \mathit{MillRecycleFeed} }[/math] array is an optional input parameter, and is set to null if omitted

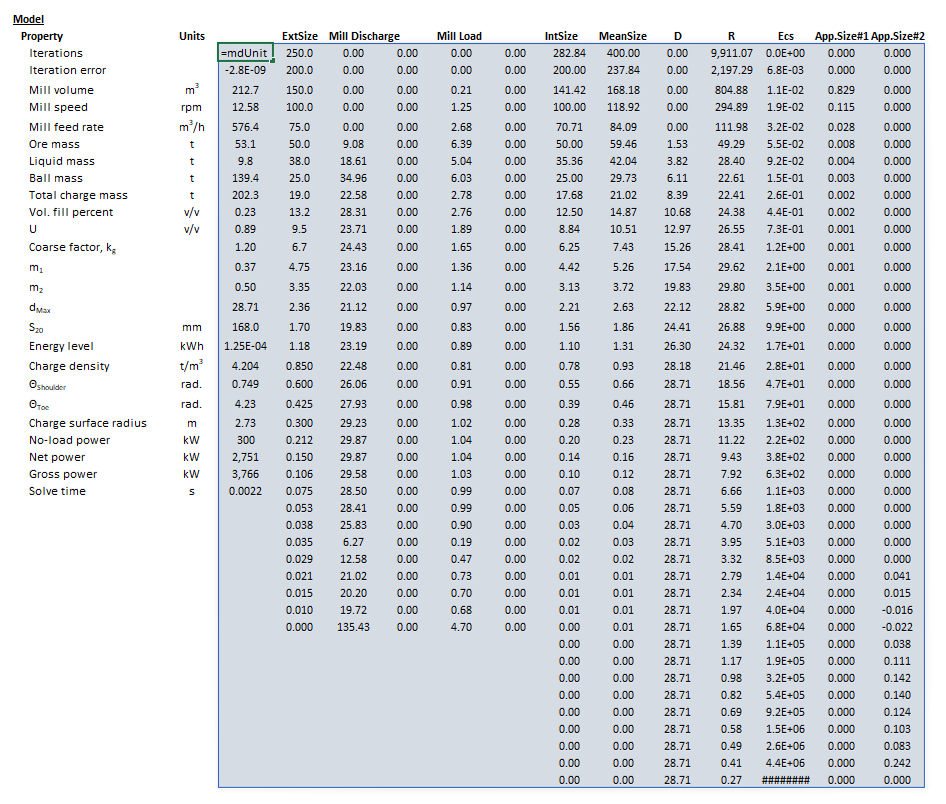

Results

The results are displayed in Excel as an array corresponding to the matrix notation below:

- [math]\displaystyle{ \mathit{mdUnit\_AGSAG\_VariableRates} = \begin{bmatrix} \begin{bmatrix} \text{Iterations}\\ \text{Iteration error}\\ V\text{ (m}^{\text{3}}\text{)}\\ \text{Mill speed (rpm)}\\ Q_{\rm V,F}\\ M_{\rm S}\text{ (t)}\\ M_{\rm L}\text{ (t)}\\ M_{\rm B}\text{ (t)}\\ M\text{ (t)}\\ J_{\rm t}\text{ (v/v)}\\ U\text{ (v/v)}\\ k_{\rm g}\text{ (-)}\\ m_1\text{ (-)}\\ m_2\text{ (-)}\\ d_{\rm max}\text{ (h}^{-1}\text{)}\\ S_{20}\text{ (mm)}\\ E_q\text{ (kWh)}\\ \rho_{\rm c}\text{ (t/m}^3\text{)}\\ \theta_{\rm S}\text{ (rad)}\\ \theta_{\rm T}\text{ (rad)}\\ r_{\rm i}\text{ (m)}\\ P_{\rm NoLoad}\text{ (kW)}\\ P_{\rm Net}\text{ (kW)}\\ P_{\rm Gross}\text{ (kW)}\\ \end{bmatrix} & \begin{array}{cccccccc} \begin{bmatrix} \hat{d}_1\text{ (mm)}\\ \vdots\\ \hat{d}_q\text{ (mm)} \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,P})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,P})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,P})_{q1}\text{ (t/h)} & \dots & (Q_{\rm M,P})_{qm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (M_{\rm S})_{11}\text{ (t)} & \dots & (M_{\rm S})_{1m}\text{ (t)}\\ \vdots & \ddots & \vdots\\ (M_{\rm S})_{q1}\text{ (t)} & \dots & (M_{\rm S})_{qm}\text{ (t)}\\ \end{bmatrix} & \begin{bmatrix} d_1\text{ (mm)}\\ \vdots\\ d_n\text{ (mm)} \end{bmatrix} & \begin{bmatrix} \bar{d}_1\text{ (mm)}\\ \vdots\\ \bar{d}_n\text{ (mm)}\\ \end{bmatrix} & \begin{bmatrix} D_{1}\left(\text{h}^\text{-1}\right)\\ \vdots\\ D_n\left(\text{h}^\text{-1}\right)\\ \end{bmatrix} & \begin{bmatrix} R_{1}\left(\text{h}^\text{-1}\right)\\ \vdots\\ R_n\left(\text{h}^\text{-1}\right)\\ \end{bmatrix} & \begin{bmatrix} (E_{\rm cs})_{1}\text{ (kWh/t)}\\ \vdots\\ (E_{\rm cs})_n\text{ (kWh/t)}\\ \end{bmatrix} & \begin{bmatrix} A_{u1}\text{ (frac)}\\ \vdots\\ A_{un}\text{ (frac)}\\ \end{bmatrix} & \begin{bmatrix} A_{v1}\text{ (frac)}\\ \vdots\\ A_{vn}\text{ (frac)}\\ \end{bmatrix}\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ & & & & & &\\ \end{array} \end{bmatrix} }[/math]

where:

- [math]\displaystyle{ \text{Iterations} }[/math] is the number of internal computation steps required to converge the load

- [math]\displaystyle{ \text{Iteration error} }[/math] is the numerical error of the converged load approximation

- [math]\displaystyle{ Q_{\rm V,F} }[/math] is the flow rate of pulp into the mill (m3/h)

- [math]\displaystyle{ \text{Mill speed} }[/math] is the rotational rate of the mill (rpm)

- [math]\displaystyle{ M_{\rm S} }[/math] is the mass of ore solids in the mill (t)

- [math]\displaystyle{ M_{\rm L} }[/math] is the mass of liquids in the mill (t)

- [math]\displaystyle{ M_{\rm B} }[/math] is the mass of balls in the mill (t)

- [math]\displaystyle{ M }[/math] is the total mass of ore, liquids and balls in the mill (t)

- [math]\displaystyle{ Q_{\rm M,P} }[/math] is product mass flow rate (t/h)

- [math]\displaystyle{ \bar{d}_i }[/math] is the geometric mean size of the internal mesh series interval that mass is retained on (mm)

Example

The images below show the selection of input arrays and output results in the Excel interface.

SysCAD

The sections and variable names used in the SysCAD interface are described in detail in the following tables.

MD_Mill page

The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here.

If this field is blank, then SysCAD will display the unit class ID. |

| Requirements | ||

| On | CheckBox | This enables the unit. If this box is not checked, then the material will pass straight through the mill with no change to the size distribution. |

| NumParallelUnits | Input | The number of parallel, identical units to simulate:

|

| Method | Fixed Discharge | The discharge particle size distribution is user defined. Different distributions can be used for different solids. |

| AG/SAG (Variable Rates) | The Variable Rates AG/SAG mill model (steady-state or dynamic) is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Rod Mill (Lynch) | The Lynch rod mill model is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Ball (Perfect Mixing) | The Perfect Mixing ball mill model (steady-state or dynamic) is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Stirred (Perfect Mixing) | The Perfect Mixing stirred mill model (steady-state or dynamic) is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Mill (Herbst-Fuerstenau) | The Herbst-Fuerstenau model is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| PowerModels | CheckBox | Show alternative mill power model calculations on the Power page. |

| MediaTrajectory | CheckBox | Show mill media rolling, sliding and free flight trajectory computations on the MediaTraj page. |

| MediaStrings | CheckBox | Show media size distributions at recharge equilibrium on the MediaStrings page. |

| Options | ||

| ShowQFeed | CheckBox | QFeed and associated tab pages (eg Sp) will become visible, showing the properties of the combined feed stream. |

| ShowQProd | CheckBox | QProd and associated tab pages (eg Sp) will become visible, showing the properties of the products. |

| SizeForPassingFracCalc | Input | Size fraction for % Passing calculation. The size fraction input here will be shown in the Stream Summary section. |

| FracForPassingSizeCalc | Input | Fraction passing for Size calculation. The fraction input here will be shown in the Stream Summary section. |

| Stream Summary | ||

| MassFlow / Qm | Display | The total mass flow in each stream. |

| SolidMassFlow / SQm | Display | The Solids mass flow in each stream. |

| LiquidMassFlow / LQm | Display | The Liquid mass flow in each stream. |

| VolFlow / Qv | Display | The total Volume flow in each stream. |

| Temperature / T | Display | The Temperature of each stream. |

| Density / Rho | Display | The Density of each stream. |

| SolidFrac / Sf | Display | The Solid Fraction in each stream. |

| LiquidFrac / Lf | Display | The Liquid Fraction in each stream. |

| Passing | Display | The mass fraction passing the user-specified size (in the field SizeForPassingFracCalc) in each stream. |

| Passes | Display | The user-specified (in the field FracForPassesSizeCalc) fraction of material in each stream will pass this size fraction. |

Mill page

The Mill page is used to specify the input parameters for the mill model.

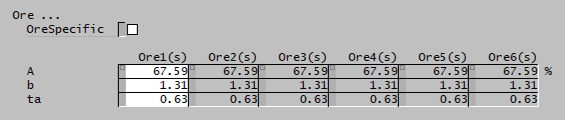

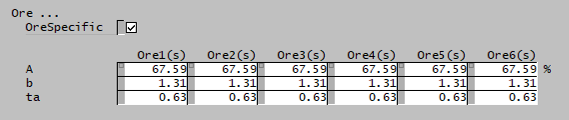

Ore page

This page is used to define the comminution properties of SysCAD species with the size distribution quality in the project.

Results page

This page is used to display the model results.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Results | ||

| Solver | ||

| Iterations | Display | Number of iterations to converge internal load solver. |

| IterationError | Display | Numerical approximation error of internal load solver. |

| Mill Properties | ||

| MillVolume | Display | Internal volume of the mill. |

| MillSpeed | Display | Rotational speed of the mill. |

| MillFeedRate / Feed.SLQv | Display | Volumetric feed rate of pulp into the mill. |

| Mill Contents | ||

| OreMass | Display | Mass of ore (solids with PSD) in the mill. |

| LiquidMass | Display | Mass of liquids in the mill. |

| BallMass | Display | Mass of ball media in the mill. |

| TotalChargeMass | Display | Total mass of ore, liquids and balls in the mill. |

| VolTotalLoad | Display | Volumetric fraction of mill volume of total charge (ore, liquids, balls and void space). |

| Mill Discharge | ||

| m1 | Display | Parameter of the Austin mill holdup relationship. |

| m2 | Display | Parameter of the Austin mill holdup relationship. |

| dMax | Display | Maximum discharge rate of load volume through the grate. |

| Charge Properties | ||

| S20 | Display | Size of the top (largest) 20% of the load. |

| ChargeDensity | Display | Density of the charge. |

| U | Display | Fraction of charge void space filled with slurry. |

| ThetaShoulder | Display | Angular position of the charge shoulder. |

| ThetaTue | Display | Angular position of the charge toe. |

| ChargeSurfaceRadius | Display | Radius of the inner charge surface. |

| Power | ||

| NoLoadPower | Display | No-load power draw of the mill. |

| NetPower | Display | Net power draw of the mill. |

| GrossPower | Display | Gross power draw of the mill. |

RiDi page

This page displays the breakage and discharge rates for each size interval computed by the model.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Rates | ||

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| R | Display | Value of breakage rate, [math]\displaystyle{ R_i }[/math], for each size interval, for each ore species. |

| D | Display | Value of discharge rate, [math]\displaystyle{ D_i }[/math], for each size interval. |

| Ecs | Display | Value of the specific comminution energy for each size interval. |

Load page

This page displays information about the balls, solids and liquids that currently comprise the mill load.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Load | ||

| SolidMass / SMt | Display | The mass of solids with the SysCAD size distribution property currently in the mill. |

| LiquidMass / LMt | Display | The mass of liquids plus solids without the SysCAD size distribution property currently in the mill. |

| BallMass / BMt | Display | The mass of ball media in the mill. |

| Size | Display | Size of each interval in the external mesh series. |

| MeanSize | Display | Geometric mean size of each interval in the external mesh series. |

| Load | Display | The mass of solids with the SysCAD size distribution property currently in the mill, by size and species. |

Power page

This optional page displays the inputs and results for alternative mill power models. The page is only visible if PowerModels is selected on the MD_Mill page.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Power | ||

| HoggFuerstenau | CheckBox | Shows inputs and results for tumbling mill power calculations using the Hogg and Fuerstenau method. |

| MorrellC | CheckBox | Shows inputs and results for tumbling mill power calculations using the Morrell Continuum method. |

| MorrellE | CheckBox | Shows inputs and results for tumbling mill power calculations using the Morrell Empirical method. |

| MorrellD | CheckBox | Shows inputs and results for tumbling mill power calculations using the Morrell Discrete Shell method. |

| HildenPowell | CheckBox | Shows inputs and results for tumbling mill power calculations using the Hilden and Powell method. |

MediaStrings page

This page displays the inputs and results for grinding mill media string calculations. The page is only visible if MediaStrings is selected on the MD_Mill page.

MediaTraj page

This page displays the inputs and results for tumbling mill media trajectory calculations. The page is only visible if MediaTrajectory is selected on the MD_Mill page.

About page

This page is provides product and licensing information about the Met Dynamics Models SysCAD Add-On.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| About | ||

| HelpLink | Opens a link to the Installation and Licensing page using the system default web browser. Note: Internet access is required. | |

| Information | Copies Product and License information to the Windows clipboard. | |

| Product | ||

| Name | Display | Met Dynamics software product name |

| Version | Display | Met Dynamics software product version number. |

| BuildDate | Display | Build date and time of the Met Dynamics Models SysCAD Add-On. |

| License | ||

| File | This is used to locate a Met Dynamics software license file. | |

| Location | Display | Type of Met Dynamics software license or file name and path of license file. |

| SiteCode | Display | Unique machine identifier for license authorisation. |

| ReqdAuth | Display | Authorisation level required, MD-SysCAD Full or MD-SysCAD Runtime. |

| Status | Display | License status, LICENSE_OK indicates a valid license, other messages report licensing errors. |

| IssuedTo | Display | Only visible if Met Dynamics license file is used. Name of organisation/seat the license is authorised to. |

| ExpiryDate | Display | Only visible if Met Dynamics license file is used. License expiry date. |

| DaysLeft | Display | Only visible if Met Dynamics license file is used. Days left before the license expires. |

See also

External links

References

- ↑ Napier-Munn, T.J., Morrell, S., Morrison, R.D. and Kojovic, T., 1996. Mineral comminution circuits: their operation and optimisation. Julius Kruttschnitt Mineral Research Centre, Indooroopilly, QLD.

- ↑ Leung, K., Morrison, R.D. and Whiten, W.J., 1987. An Energy Based Ore Specific Model for Autogenous and Semi-autogenous Grinding, Copper 87, Vina del Mar, Vol. 2, pp 71 - 86

- ↑ Morrell, S. and Morrison, R.D., 1996. AG and SAG mill circuit selection and design by simulation. In International Conference on Autogenous and Semiautogenous Grinding Technology (Vol. 2, pp. 769-790).

- ↑ Morrell, S., Valery, W., Banini, G. and Latchireddi, S., 2001. Developments in AG/SAG mill modelling. Proceedings of Autogenous and Semiautogenous Grinding Technology, Vancouver, pp.71-84.