Rod Mill (Lynch)

Description

This article describes an implementation of the Lynch (1977) rod mill model.[1][2]

Model theory

Excel

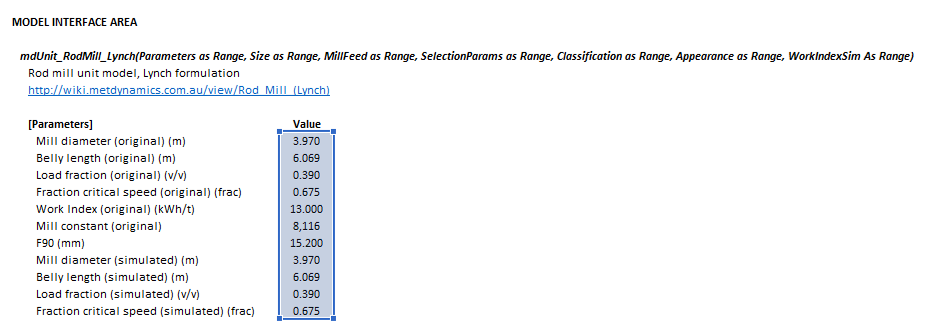

The Lynch rod mill model may be invoked from the Excel formula bar with the following function call:

=mdUnit_RodMill_Lynch(Parameters as Range, Size as Range, MillFeed as Range, SelectionParams as Range, Classification as Range, Appearance as Range, WorkIndexSim As Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

Inputs

The required inputs are defined below in matrix notation with elements corresponding to cells in Excel row ([math]\displaystyle{ i }[/math]) x column ([math]\displaystyle{ j }[/math]) format:

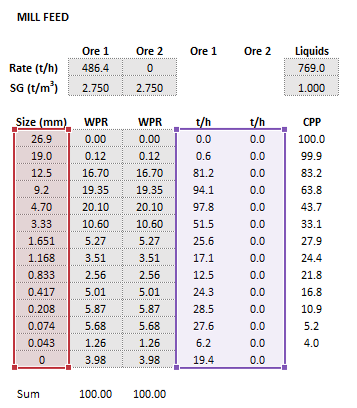

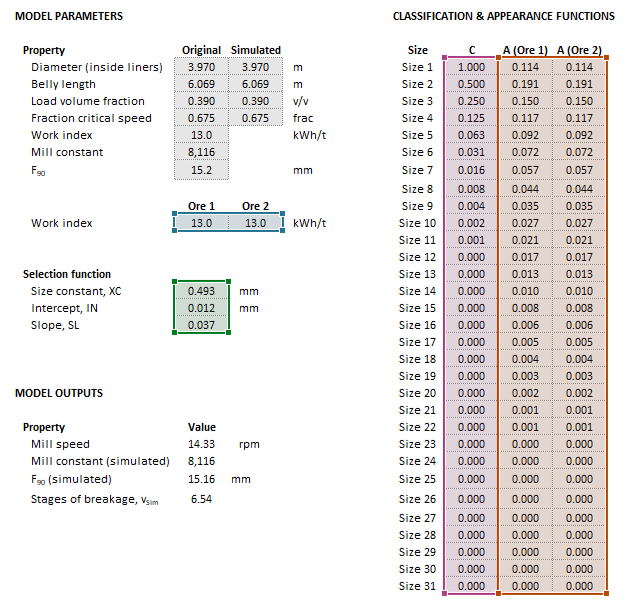

- [math]\displaystyle{ Parameters= \begin{bmatrix} D_{\rm Orig}\text{ (m)}\\ L_{\rm Orig}\text{ (m)}\\ \mathit{LF}_{\rm Orig}\text{ (v/v)}\\ \mathit{FracCS}_{\rm Orig}\text{ (frac)}\\ \mathit{WI}_{\rm Orig}\text{ (kWh/t)}\\ MC_{\rm Orig}\\ (F_{90})_{\rm Orig}\text{ (mm)}\\ D_{\rm Sim}\text{ (m)}\\ L_{\rm Sim}\text{ (m)}\\ \mathit{LF}_{\rm Sim}\text{ (v/v)}\\ \mathit{FracCS}_{\rm Sim}\text{ (frac)}\\ \end{bmatrix},\;\;\;\;\;\; Size = \begin{bmatrix} d_{1}\text{ (mm)}\\ \vdots\\ d_n\text{ (mm)}\\ \end{bmatrix},\;\;\;\;\;\; MillFeed= \begin{bmatrix} (Q_{\rm M,F})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,F})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{nm}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; SelectionParams= \begin{bmatrix} \mathit{XC}\text{ (mm)}\\ \mathit{IN}\text{ (mm)}\\ \mathit{SL}\\ \end{bmatrix} }[/math]

- [math]\displaystyle{ Classification= \begin{bmatrix} C_{1}\text{ (frac)}\\ \vdots\\ C_{31}\text{ (frac)}\\ \end{bmatrix},\;\;\;\;\;\; Appearance= \begin{bmatrix} \begin{bmatrix} A_{1}\text{ (frac)}\\ \vdots\\ A_{31}\text{ (frac)}\\ \end{bmatrix}_1 \dots \begin{bmatrix} A_{1}\text{ (frac)}\\ \vdots\\ A_{31}\text{ (frac)}\\ \end{bmatrix}_m \end{bmatrix},\;\;\;\;\;\; \mathit{WI}_{\rm Sim}= \begin{bmatrix} \mathit{WI}_{1}\text{ (kWh/t)} & \dots & \mathit{WI}_m\text{ (kWh/t)}\\ \end{bmatrix}\;\;\;\;\;\; }[/math]

where:

- [math]\displaystyle{ D }[/math] is mill diameter (m)

- [math]\displaystyle{ L }[/math] is mill length (m)

- [math]\displaystyle{ \mathit{LF} }[/math] is load fraction, the load volume as a fraction of mill volume (v/v)

- [math]\displaystyle{ \mathit{FracCS} }[/math] is the fraction critical speed of the mill (frac)

- [math]\displaystyle{ \mathit{WI} }[/math] is the Bond Ball Work Index of the ore (kWh/t)

- [math]\displaystyle{ \mathit{MC} }[/math] is the mill constant

- [math]\displaystyle{ F_{90} }[/math] is 90% passing size in the mill feed (mm)

- [math]\displaystyle{ n }[/math] is the number of size intervals

- [math]\displaystyle{ m }[/math] is the number of ore types

- [math]\displaystyle{ d_i }[/math] is the size of the square mesh interval that feed mass is retained on (mm)

- [math]\displaystyle{ d_{i+1}\lt d_i\lt d_{i-1} }[/math], i.e. descending size order from top size ([math]\displaystyle{ d_{1} }[/math]) to sub mesh ([math]\displaystyle{ d_{n}=0 }[/math] mm)

- [math]\displaystyle{ Q_{\rm M,F} }[/math] is the mass flow rate of particles in the feed (t/h)

- [math]\displaystyle{ \mathit{XC} }[/math] is the Selection function size constant (mm)

- [math]\displaystyle{ \mathit{IN} }[/math] is the Selection function intercept (mm)

- [math]\displaystyle{ \mathit{SL} }[/math] is the Selection function slope

- [math]\displaystyle{ C }[/math] is the Classification function (frac)

- [math]\displaystyle{ A }[/math] is the Appearance function (frac)

- the [math]\displaystyle{ Orig }[/math] and [math]\displaystyle{ Sim }[/math] subscripts refer to the original and simulated mills, respectively.

Results

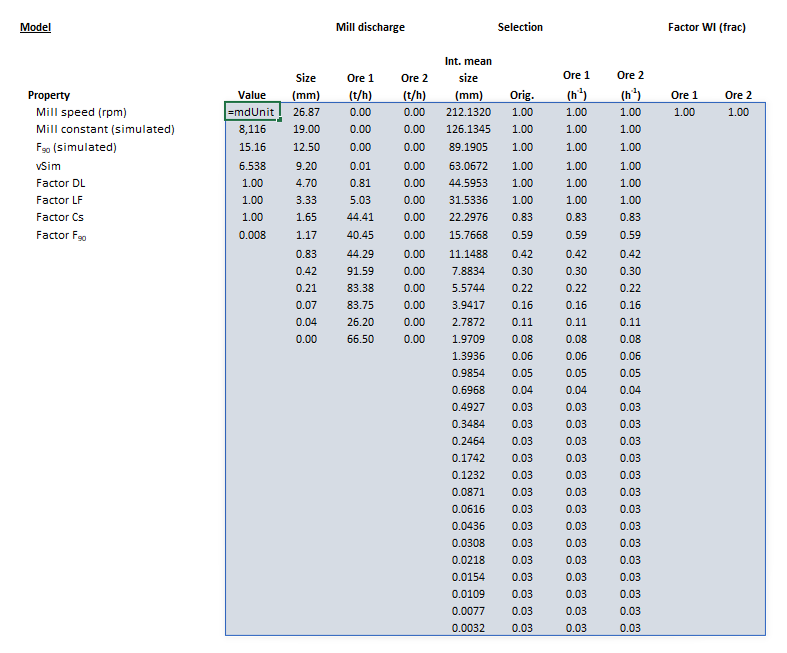

The results are displayed in Excel as an array corresponding to the matrix notation below:

- [math]\displaystyle{ mdUnit\_RodlMill\_Lynch = \begin{bmatrix} \begin{bmatrix} \text{Mill speed (rpm)}\\ MC_{\rm Sim}\\ v_{\rm Sim}\\ Factor_{\rm DL}\text{ (-)}\\ Factor_{\rm LF}\text{ (-)}\\ Factor_{\rm CS}\text{ (-)}\\ Factor_{F_{90}}\text{ (-)}\\ \end{bmatrix} & \begin{array}{cccccc} \begin{bmatrix} d_1\text{ (mm)}\\ \vdots\\ d_n\text{ (mm)} \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,P})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,P})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,P})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,P})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} \bar{d}_1\text{ (mm)}\\ \vdots\\ \bar{d}_{31}\text{ (mm)}\\ \end{bmatrix} & \begin{bmatrix} (S_1)_{\rm Orig}\text{ (h}^{-1}\text{)}\\ \vdots\\ (S_{31})_{\rm Orig}\text{ (h}^{-1}\text{)}\\ \end{bmatrix} & \begin{bmatrix} \begin{bmatrix} S_{1}\text{ (h}^{-1}\text{)}\\ \vdots\\ S_{31}\text{ (h}^{-1}\text{)}\\ \end{bmatrix}_1 \dots \begin{bmatrix} S_{1}\text{ (h}^{-1}\text{)}\\ \vdots\\ S_{31}\text{ (h}^{-1}\text{)}\\ \end{bmatrix}_m \end{bmatrix} & \begin{array}{c} \begin{bmatrix} (Factor_{\rm WI})_1 & \dots & (Factor_{\rm WI})_m \end{bmatrix}\\ \\ \\ \end{array} \\ \\ \\ \\ \\ \end{array} \end{bmatrix} }[/math]

where:

- [math]\displaystyle{ \text{Mill speed} }[/math] is the rotational rate of the mill (rpm)

- [math]\displaystyle{ v_{\rm Sim} }[/math] is the number of breakage stages

- [math]\displaystyle{ Q_{\rm M,P} }[/math] is the mass flow rate of particles in the mill product (t/h)

- [math]\displaystyle{ \bar{d}_i }[/math] is the geometric mean size of the internal mesh series interval that mass is retained on (mm)

- [math]\displaystyle{ S }[/math] is the Selection function (h-1)

- [math]\displaystyle{ Factor_{\rm DL} }[/math], [math]\displaystyle{ Factor_{\rm LF} }[/math], [math]\displaystyle{ Factor_{\rm CS} }[/math], [math]\displaystyle{ Factor_{F_{}90} }[/math], and [math]\displaystyle{ Factor_{\rm WI} }[/math] are the selection function scaling factors associated with dimaeter-length, load fraction, fraction critical speed, F_90 and Work Index, respectively (frac)

Example

The images below show the selection of input arrays and output results in the Excel interface.

SysCAD

The sections and variable names used in the SysCAD interface are described in detail in the following tables.

MD_Mill page

The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here.

If this field is blank, then SysCAD will display the unit class ID. |

| Requirements | ||

| On | CheckBox | This enables the unit. If this box is not checked, then the material will pass straight through the mill with no change to the size distribution. |

| NumParallelUnits | Input | The number of parallel, identical units to simulate:

|

| Method | Fixed Discharge | The discharge particle size distribution is user defined. Different distributions can be used for different solids. |

| AG/SAG (Variable Rates) | The Variable Rates AG/SAG mill model (steady-state or dynamic) is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Rod Mill (Lynch) | The Lynch rod mill model is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Ball (Perfect Mixing) | The Perfect Mixing ball mill model (steady-state or dynamic) is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Stirred (Perfect Mixing) | The Perfect Mixing stirred mill model (steady-state or dynamic) is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| Mill (Herbst-Fuerstenau) | The Herbst-Fuerstenau model is used to determine the mill product size distribution. Different parameters can be used for different solids. | |

| PowerModels | CheckBox | Show alternative mill power model calculations on the Power page. |

| MediaTrajectory | CheckBox | Show mill media rolling, sliding and free flight trajectory computations on the MediaTraj page. |

| MediaStrings | CheckBox | Show media size distributions at recharge equilibrium on the MediaStrings page. |

| Options | ||

| ShowQFeed | CheckBox | QFeed and associated tab pages (eg Sp) will become visible, showing the properties of the combined feed stream. |

| ShowQProd | CheckBox | QProd and associated tab pages (eg Sp) will become visible, showing the properties of the products. |

| SizeForPassingFracCalc | Input | Size fraction for % Passing calculation. The size fraction input here will be shown in the Stream Summary section. |

| FracForPassingSizeCalc | Input | Fraction passing for Size calculation. The fraction input here will be shown in the Stream Summary section. |

| Stream Summary | ||

| MassFlow / Qm | Display | The total mass flow in each stream. |

| SolidMassFlow / SQm | Display | The Solids mass flow in each stream. |

| LiquidMassFlow / LQm | Display | The Liquid mass flow in each stream. |

| VolFlow / Qv | Display | The total Volume flow in each stream. |

| Temperature / T | Display | The Temperature of each stream. |

| Density / Rho | Display | The Density of each stream. |

| SolidFrac / Sf | Display | The Solid Fraction in each stream. |

| LiquidFrac / Lf | Display | The Liquid Fraction in each stream. |

| Passing | Display | The mass fraction passing the user-specified size (in the field SizeForPassingFracCalc) in each stream. |

| Passes | Display | The user-specified (in the field FracForPassesSizeCalc) fraction of material in each stream will pass this size fraction. |

Mill page

The Mill page is used to specify the input parameters for the mill model.

Ore page

This page is used to define the comminution properties of SysCAD species with the size distribution quality in the project.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

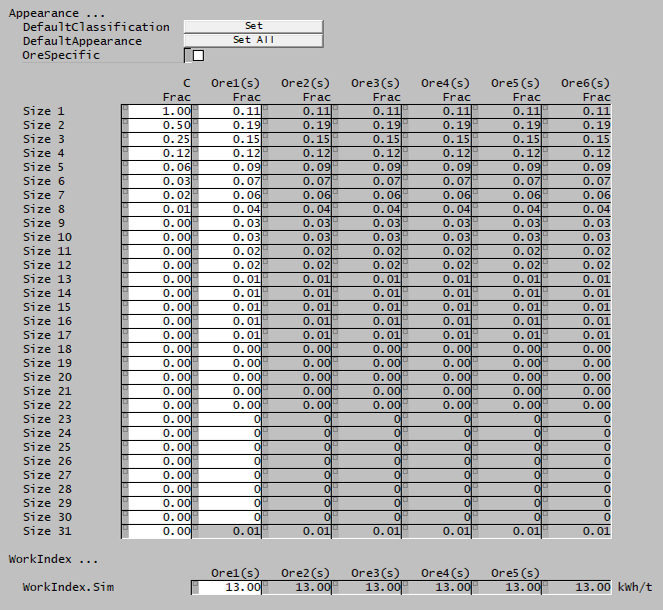

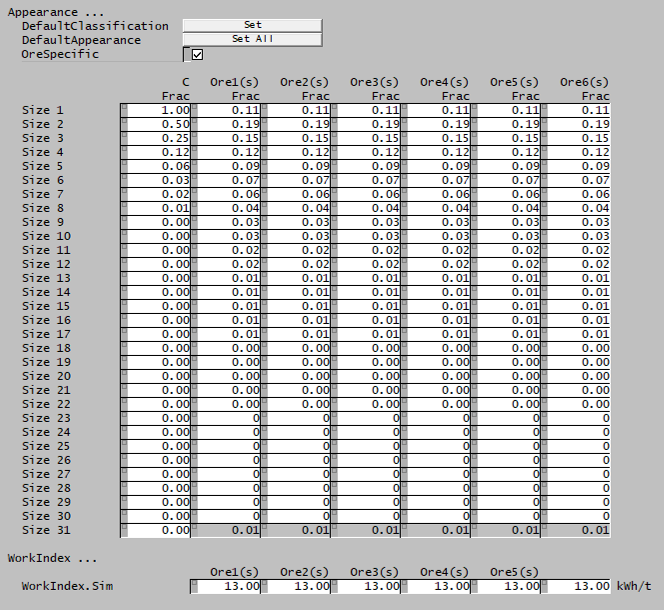

| Appearance | ||

| DefaultClassification | Sets the Classification function to the default values. | |

| DefaultAppearance | Sets all species to the default Broadbent-Callcott Appearance function. | |

| OreSpecific | CheckBox |

|

| Appearance | Input | User-specified Appearance function data for all species with size distribution property. |

| WorkIndex | ||

| WorkIndex.Sim | Input | Bond Rod Work Index data for all species with size distribution property. |

Selection page

This page displays the selection function values computed for the Lynch rod mill model.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Scaling | ||

| Diameter | Display | Value of the mill diameter-length factor for rate scaling. |

| LoadFraction | Display | Value of the load fraction factor for rate scaling. |

| FracCS | Display | Value of the fraction critical speed factor for rate scaling. |

| F90 | Display | Value of the F90 factor for rate scaling. |

| WorkIndex | Display | Value of the Work Index factor of each ore species for rate scaling. |

| Selection | ||

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| Orig | Display | Value of original selection function at at size interval. |

| Selection | Display | Value of selection function of the simulated mill for each size interval, for each ore species. |

Power page

This optional page displays the inputs and results for alternative mill power models. The page is only visible if PowerModels is selected on the MetDynamics*Mill page.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Power | ||

| HoggFuerstenau | CheckBox | Shows inputs and results for tumbling mill power calculations using the Hogg and Fuerstenau method. |

| MorrellC | CheckBox | Shows inputs and results for tumbling mill power calculations using the Morrell Continuum method. |

| MorrellE | CheckBox | Shows inputs and results for tumbling mill power calculations using the Morrell Empirical method. |

MediaStrings page

This page displays the inputs and results for grinding mill media string calculations. The page is only visible if MediaStrings is selected on the MetDynamics*Mill page.

MediaTraj page

This page displays the inputs and results for tumbling mill media trajectory calculations. The page is only visible if MediaTrajectory is selected on the MetDynamics*Mill page.

About page

This page is provides product and licensing information about the Met Dynamics Models SysCAD Add-On.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| About | ||

| HelpLink | Opens a link to the Installation and Licensing page using the system default web browser. Note: Internet access is required. | |

| Information | Copies Product and License information to the Windows clipboard. | |

| Product | ||

| Name | Display | Met Dynamics software product name |

| Version | Display | Met Dynamics software product version number. |

| BuildDate | Display | Build date and time of the Met Dynamics Models SysCAD Add-On. |

| License | ||

| File | This is used to locate a Met Dynamics software license file. | |

| Location | Display | Type of Met Dynamics software license or file name and path of license file. |

| SiteCode | Display | Unique machine identifier for license authorisation. |

| ReqdAuth | Display | Authorisation level required, MD-SysCAD Full or MD-SysCAD Runtime. |

| Status | Display | License status, LICENSE_OK indicates a valid license, other messages report licensing errors. |

| IssuedTo | Display | Only visible if Met Dynamics license file is used. Name of organisation/seat the license is authorised to. |

| ExpiryDate | Display | Only visible if Met Dynamics license file is used. License expiry date. |

| DaysLeft | Display | Only visible if Met Dynamics license file is used. Days left before the license expires. |

References

- ↑ Lynch, A.J., 1977. Mineral Crushing and Grinding Circuits: Their Simulation, Optimisation, Design and Control. Elsevier, Amsterdam.

- ↑ Napier-Munn, T.J., Morrell, S., Morrison, R.D. and Kojovic, T., 1996. Mineral comminution circuits: their operation and optimisation. Julius Kruttschnitt Mineral Research Centre, Indooroopilly, QLD.