Flotation Cell (Savassi, Dynamic): Difference between revisions

Scott Munro (talk | contribs) m (1 revision imported) |

imported>Scott.Munro mNo edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Description == | == Description == | ||

This article describes a '''''dynamic''''' implementation of the Savassi (2005) flotation model.{{Savassi (2005)}} | This article describes a '''''dynamic''''' implementation of the Savassi (2005) flotation model for use in time-dependent simulations of mechanical flotation cells..{{Savassi (2005)}} | ||

The dynamic version uses the same underlying theory and structure as the steady-state Savassi flotation model. For a full description of the steady-state model, see [[Flotation Cell (Savassi)]]. | |||

== Model theory == | == Model theory == | ||

{{ | {{Restricted content}} | ||

[[File:FlotationSavassiDynamic1.png|thumb|600px|Figure 1. Schematic of a flotation cell.]] | |||

<div class="user-show"> | |||

=== Floatability classes === | |||

</div><hide> | |||

Much of the original literature underpinning the modelling approach described here refers to the notion of a ''floatability class'', which groups all particles that exhibit similar floatability properties, without any particular reference to particle sizes or mineral compositions within the class.{{Runge et al. (1998)}} In order to align the flotation modelling approach with the comminution, classification and concentration processes described in other articles, a distinction is made between ''particle size'' and ''floatability component''. | |||

The mathematical relations below are developed on the basis of a particle size class which is further subdivided into floatability components. This allows the definition of floatability rate groups (e.g. fast, slow, non-floating) within mineral types (e.g. chalcopyrite, pyrite, non-sulphide gangue), by size fraction. | |||

</hide><div class="user-show"> | |||

=== Unsteady-state mass balance === | |||

</div><hide> | |||

The dynamic Savassi flotation model is based on an unsteady-state balance of floatability component and liquid masses entering the cell and leaving via the tailings or concentrate streams. A mass balance of solids and liquids around a flotation cell yields:{{Quintanilla et al. (2021)}} | |||

:<math>\dfrac{{\rm d}M_{ij}}{{\rm d} t} = m_{ij,{\rm F}} - m_{ij,{\rm T}} - m_{ij,{\rm C}}, \quad \dfrac{{{\rm d} M}_{\rm L}}{{\rm d} t} = m_{\rm L,F} - m_{\rm L,T} - m_{\rm L,C}</math> | |||

where: | |||

* <math>i</math> is the index of the size interval, <math>i = \{1,2,\dots,n\}</math>, <math>n</math> is the number of size intervals | |||

* <math>j</math> is the index of the floatability component, <math>j = \{1,2,\dots,m\}</math>, <math>m</math> is the number of floatability components (e.g. mineral types, fast/slow types etc.) | |||

* <math>M_{ij}</math> and <math>M_{\rm L}</math> are the masses of particles of size fraction <math>i</math> and floatability component type <math>j</math> and liquids, respectively, in the cell (t) | |||

* <math>m_{ij,{\rm F}}</math>, <math>m_{ij,{\rm T}}</math>, and <math>m_{ij,{\rm C}}</math> are the mass flow rates of particles of size fraction <math>i</math> and floatability component type <math>j</math> in the cell ''feed'', ''tailings'', and ''concentrate'' streams, respectively (t/min) | |||

* <math>m_{\rm L,F}</math>, <math>m_{\rm L,T}</math>, and <math>m_{\rm L,C}</math> are the mass flow rates of liquids in the cell ''feed'', ''tailings'', and ''concentrate'' streams, respectively (t/min) | |||

Mass flow to concentrate consists of mass recovered by the processes of ''true flotation'', <math>m_{{\rm TF},ij}</math> (t/min), and ''entrainment'', <math>m_{{\rm ENT},ij}</math> (t/min):{{Roine et al. (2011)}} | |||

:<math>m_{ij,{\rm C}} = m_{ij,{\rm TF}} + m_{ij,{\rm ENT}}</math> | |||

See Figure 1 for a schematic representation of the flotation cell and mass balance components. | |||

</hide><div class="user-show"> | |||

==== Recovery by true flotation ==== | |||

</div><hide> | |||

Particle collection and recovery in flotation is generally considered to be a first order rate process: | |||

:<math>\dfrac{{\rm d} c_{ij}}{{\rm d} t} = -k_{ij} c_{ij}</math> | |||

where <math>c_{ij}</math> is the concentration of particles of size fraction <math>i</math> and floatability component type <math>j</math> remaining in the cell (t/m<sup>3</sup>), and <math>k_{ij}</math> is the first order rate constant of the same particles (min<sup>-1</sup>). | |||

Therefore, the mass flow rate of particles to concentrate via true flotation can be expressed as: | |||

:<math>m_{ij,{\rm TF}} = k_{ij} M_{ij}</math> | |||

The first order rate constant, <math>k_{ij}</math>, has been related to ore floatability, bubble flux, froth zone properties, and cell scale-up factors by:{{Gorain et al. (1997d)}}{{Alexander and Morrison (1998)}}{{Runge et al. (2003)}} | |||

:<math>k_{ij} = P_{ij} \cdot (S_{\rm b} \cdot 60) \cdot Rf_{ij} \cdot C_{ij}</math> | |||

where: | |||

* <math>P_{ij}</math> is the floatability of particles of size <math>i</math> and floatability component type <math>j</math> (frac) | |||

* <math>S_{\rm b}</math> is the bubble surface area flux (m<sup>2</sup>/s/m<sup>2</sup>) | |||

* <math>Rf_{ij}</math> is the fraction of collected particles of size <math>i</math> and floatability component <math>j</math> recovered by froth (frac) | |||

* <math>C_{ij}</math> is a cell scale-up factor that relates flotation performance between cells of different sizes (e.g. laboratory versus industrial) (frac) | |||

The residence time of particles in the froth zone is typically of the order of ''seconds'', compared to ''minutes'' in the collection zone. Therefore, this model implementation assumes froth recovery occurs instantaneously as a part of true flotation. No froth zone transport delays are included. | |||

</hide><div class="user-show"> | |||

==== Recovery by entrainment ==== | |||

</div><hide> | |||

In Savassi et al.'s original approach (2005), the fraction of feed mass recovered to concentrate by entrainment, <math>R_{ij, \rm ENT}</math> (frac), is related to the recovery of feed water to concentrate, <math>R_{\rm w}</math> (frac), by:{{Savassi (2005)}} | |||

:<math>R_{ij, \rm ENT} = \mathrm{ENT}_{ij} \cdot R_{\rm w}</math> | |||

where <math>\mathrm{ENT}_{ij}</math> is the fraction of particles of size <math>i</math> and floatability component <math>j</math> recovered by entrainment (frac). | |||

For dynamic simulation, the mass flow rate of particles recovered by entrainment (<math>m_{ij, \rm ENT}</math>) must be decoupled from the flow rates of particles and water in the feed stream that are implicit in the <math>R_{ij, \rm ENT}</math> and <math>R_{\rm w}</math> terms. | |||

Therefore, a relationship for recovery by entrainment based on the contents of the collection zone is used:{{Zheng et al. (2006)}} | |||

:<math>\mathrm{ENT}_{ij} = \dfrac{m_{ij,{\rm ENT}}}{m_{\rm L,C}} \cdot \dfrac{M_{\rm L}}{M_{ij}} \quad \implies \quad m_{ij,{\rm ENT}} = \mathrm{ENT}_{ij} \cdot \dfrac{m_{\rm L,C} \cdot M_{ij}}{M_{\rm L}}</math> | |||

The feed water and collection zone recovery-entrainment relationships are equivalent at steady-state. | |||

</hide><div class="user-show"> | |||

==== Tailings discharge ==== | |||

</div><hide> | |||

The collection zone of a conventional flotation cell is considered to be perfectly mixed.{{Savassi (2005)}} Therefore, the mass flowrate of particles and liquids in the tailings can be expressed as: | |||

:<math>m_{ij,{\rm T}} = c_{ij} Q_{\rm tail} = \dfrac{M_{ij}}{V_{\rm effective}} \cdot Q_{\rm tail}, \quad m_{\rm L,T} = c_L Q_{\rm tail} = \dfrac{M_{\rm L}}{V_{\rm effective}} \cdot Q_{\rm tail}</math> | |||

where: | |||

* <math>Q_{\rm tail}</math> is the volumetric flow rate of the tailings stream (m<sup>3</sup>/min) | |||

* <math>V_{\rm effective}</math> is the ''effective'' volume of pulp in the collection zone of the cell (m<sup>3</sup>), i.e. excluding froth and gas hold up. See [[Flotation Cell (Savassi, Dynamic)#Pulp_volume|Pulp volume]] below for more information. | |||

* <math>c_{\rm L}</math> is the concentration of liquids in the cell (t/m<sup>3</sup>) | |||

In a dynamic simulation, the tailing flows flow rate is a model input parameter. The flow rate is typically set by the user or a simulated process control system in order to maintain a target pulp level (or froth depth) in the cell. | |||

</hide><div class="user-show"> | |||

==== Time step discretisation ==== | |||

</div><hide> | |||

The dynamic population balance differential equation is numerically solved by a discretised time stepping approach (i.e. [https://en.wikipedia.org/wiki/Euler_method Euler's method]). The change in mass of a particle of type <math>M_{ij}</math> in the collection zone during a sufficiently small time increment <math>\Delta t = t_{n+1} - t_{n}</math> is: | |||

:<math>\Delta M_{ij} = \big ( m_{ij,{\rm F}} - m_{ij,{\rm TF}} - m_{ij,{\rm ENT}} - m_{ij,{\rm T}} \big ) . \Delta t</math> | |||

Similarly, for liquids: | |||

:<math>\Delta M_{\rm L} = \left ( m_{\rm L,F} - m_{\rm L,C} - m_{\rm L,T}\right ). \Delta t</math> | |||

The time stepping approach is a convenient numerical approximation to the solution of the unsteady-state population balance differential equation. The approach is, however, subject to several limitations: | |||

* The mass of liquids or particles of a given size and floatability class discharged from the cell in a time step cannot exceed the mass of liquids or particles of that type actually present in the cell. | |||

* Similarly, the overall maximum discharge flow rate of pulp from the cell cannot exceed the total volume of pulp in the cell in a time step. | |||

* Large time step sizes can result in oscillations or instability in the numerical solution to the first order kinetic rate equations, i.e. the [https://en.wikipedia.org/wiki/Courant-Friedrichs-Lewy_condition Courant-Friedrichs-Lewy condition]. | |||

The time step size used internally by the model is automatically reduced to ensure the kinetic rate and pulp flow rate limits per step are not exceeded. This is achieved by computing a number of sequential sub-steps at the reduced internal step size for each requested external step. | |||

This is useful if a fixed time step specified by an application is too large or a numerical solution is desired in as few steps as possible. The automatic time step adjustment is largely invisible to the user and manifests only as a slightly slower execution speed. | |||

The calculated time step size may be overridden with a larger user-specified sub-step count (or reduced time step size) if increased accuracy in the numerical approximation is desired. | |||

</hide><div class="user-show"> | |||

==== Steady-state equivalence ==== | |||

</div><hide> | |||

The unsteady-state mass transfer relations described here produce the same result as the [[Flotation Cell (Savassi)#Recovery|steady-state recovery equations]] if the cell is dynamically simulated for a suitable time (approximately [[#Residence_time|cell residence time]]) with unchanging feed and cell conditions. | |||

</hide><div class="user-show"> | |||

=== Pulp volume === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Pulp Volume)}} | |||

</hide><div class="user-show"> | |||

=== Gas hold-up === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Gas Hold-up)}} | |||

</hide><div class="user-show"> | |||

=== Residence time === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Residence Time)}} | |||

In dynamic simulation, time is explicitly included in mass transfer calculations via the <math>\Delta t</math> parameter. The residence time value above is provided for information-only. | |||

</hide><div class="user-show"> | |||

=== Bubble surface area flux === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Bubble Surface Area Flux)}} | |||

</hide><div class="user-show"> | |||

=== Froth recovery === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Froth Recovery)}} | |||

</hide><div class="user-show"> | |||

=== Entrainment === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Entrainment)}} | |||

</hide><div class="user-show"> | |||

=== Water recovery === | |||

</div><hide> | |||

{{Model theory (Text, Flotation Cell, Savassi, Water Recovery)}} | |||

</hide><div class="user-show"> | |||

==== Water rate function ==== | |||

</div><hide> | |||

The ''water rate function'' adopts a first order kinetic relationship between water recovery and pulp residence time, i.e.: | |||

:<math>\dfrac{{\rm d} c_{\rm L}}{{\rm d} t} = -k_{\rm w} c_{\rm L} \quad \implies \quad m_{\rm L,C} = k_{\rm w} M_{\rm L}</math> | |||

where <math>k_{\rm w}</math> is the kinetic rate parameter (min<sup>-1</sup>) for the recovery of water to the concentrate stream. | |||

This reduces to the [[Flotation Cell (Savassi)#Water_rate_function|Flotation Cell (Savassi) water rate function]] when the cell is perfectly mixed and at steady-state. | |||

</hide><div class="user-show"> | |||

=== Additional dynamic simulation considerations === | |||

</div><hide> | |||

The dynamic simulation of a flotation cell requires several additional considerations compared to the [[Flotation Cell (Savassi)|steady-state case]]. These are addressed below. | |||

</hide><div class="user-show"> | |||

==== Froth depth and pulp level ==== | |||

</div><hide> | |||

In the steady-state case, the froth depth and pulp level are fixed, user-specified parameters. However, in dynamic simulation, froth depth and pulp level are continuously-changing functions of the current cell contents (pulp, air) and concentrate/tailings discharge flow rates. | |||

As shown in Figure 1, froth depth, <math>H_{\rm f}</math> (m), is related to cell height, <math>H_{\rm cell}</math> (m), and pulp level, <math>H_{\rm pulp}</math> (m), by: | |||

:<math>H_{\rm f} = H_{\rm cell} - H_{\rm pulp} = \dfrac{V_{\rm cell} - V_{\rm mechanism}}{A_{\rm cell}} - \dfrac{V_{\rm pulp}}{A_{\rm cell} (1 - \epsilon_{\rm gas})}</math> | |||

where <math>V_{\rm pulp}</math> is the total volume of solids and liquids in the cell (m<sup>3</sup>). | |||

This model implementation also provides a user-specified ''maximum froth depth'', <math>H_{\rm f,max}</math> (m), which represents the limit of froth stability. Concentrate will not flow over the lip of the cell if the distance between the lip and the pulp level, i.e. <math>H_{\rm cell} - H_{\rm pulp}</math>, exceeds the maximum froth depth, e.g. when the cell is initially filling from empty. | |||

</hide><div class="user-show"> | |||

==== Feed and tailings discharge height ==== | |||

</div><hide> | |||

Flotation cells are typically arranged in series, forming a ''bank'' of cells: | |||

* Cells may be installed at progressively lower elevations along the bank. | |||

* Combined with the pulp levels in each cell, this creates hydrostatic pressure differentials that drive slurry flow from the first to the last cell. | |||

* Adjacent cells may be connected via flow control valves or simpler arrangements such as open flanges, pipes, or weirs. | |||

Given these configuration possibilities, the elevation of the feed and tailings discharge points, along with the pulp level, play an important role in determining the flow rates between cells and from the final cell in the bank. | |||

This model provides two height-related input parameters per cell; the ''feed height fraction'', <math>h_{\rm feed}</math> (frac), and the ''tailings discharge height fraction'', <math>h_{\rm tail}</math> (frac). The absolute feed and tailings discharge heights (see Figure 1) are then calculated based on the total cell height <math>H_{\rm cell}</math> as: | |||

:<math>H_{\rm feed} = h_{\rm feed} \cdot H_{\rm cell}, \quad H_{\rm tail} = h_{\rm tail} \cdot H_{\rm cell}</math> | |||

From these, the hydrostatic pressures at the feed and tailings discharge points, <math>P_{\rm feed}</math> and <math>P_{\rm tail}</math> (kPa), are computed as: | |||

:<math>P_{\rm feed} = \rho_{\rm cell} \cdot g \cdot (H_{\rm pulp} - H_{\rm feed}), \quad P_{\rm tail} = \rho_{\rm cell} \cdot g \cdot (H_{\rm pulp} - H_{\rm tail})</math> | |||

where <math>\rho_{\rm cell}</math> is the density of the cell contents, including solids, liquids and air (t/m<sup>3</sup>): | |||

:<math>\rho_{\rm cell} = (1.0 - \epsilon_{\rm Gas}) \cdot \rho_{\rm pulp} + \epsilon_{\rm Gas} \cdot \rho_{\rm air}</math> | |||

and: | |||

* <math>\rho_{\rm pulp}</math> is the density of the cell pulp (solids and liquids) (t/m<sup>3</sup>) | |||

* <math>\rho_{\rm air}</math> is the density of air (t/m<sup>3</sup>) | |||

* <math>g</math> is the acceleration due to gravity (m/s<sup>2</sup>). | |||

These hydrostatic pressures are evaluated at each time step of the dynamic simulation. Due to the wide variety of possible valve types, flow-control relationships, and connection geometries, the actual inter-cell flow rates are not computed by this model. Instead, users may easily implement flow logic externally (e.g. via SysCAD PGM) to suit their specific configuration. | |||

</hide><div class="user-show"> | |||

==== Froth Carry Rate and Lip Loading ==== | |||

</div><hide> | |||

The ''Froth Carry Rate'' (FCR) is defined as the mass flow rate of concentrate solids per unit area of the froth surface (t/h/m<sup>2</sup>): | |||

:<math>{\rm FCR} = \dfrac{\sum \limits_{i=1}^n \sum \limits_{j=1}^m m_{ij,{\rm C}}}{A_{\rm cell}}</math> | |||

Similarly, the ''Lip Loading'' (LL) represents the mass of solids crossing the cell lip per unit length (t/m): | |||

:<math>{\rm LL} = \dfrac{\sum \limits_{i=1}^n \sum \limits_{j=1}^m m_{ij,{\rm C}}}{L_{\rm lip}}</math> | |||

where <math>{L_{\rm lip}}</math> is the lip length (m). | |||

The ''maximum froth carry rate'', <math>{\rm FCR}_{\rm max}</math> (t/h/m<sup>2</sup>), and ''maximum lip loading'', <math>{\rm LL}_{\rm max}</math> (t/m), parameters limit the maximum possible flow rate of solids to concentrate. Any solids mass flow in excess of the maximum FCR or LL at a time step is returned to the collection zone pulp phase. | |||

</hide><div class="user-show"> | |||

==== Cell overflow ==== | |||

</div><hide> | |||

A cell can overflow once the pulp level reaches the cell lip height. This can arise when the cell feed flow rate continually exceeds the total discharge rate, for example. | |||

In such cases, any excess cell contents are directed to the concentrate stream. This may result in large concentrate flows at essentially tailings composition and can be avoided by implementing an effective discharge flow-level control scheme. | |||

</hide><div class="user-show"> | |||

==== Recovery ==== | |||

</div><hide> | |||

In steady-state systems, recovery is typically defined as the fraction of feed mass reporting to the concentrate stream. In a dynamic simulation, this definition is less appropriate as cell discharge is governed by the evolving cell contents rather than the instantaneous feed at any given time. | |||

To better reflect this behavior, this model implementation defines recovery as the fraction of total discharge mass reporting to the concentrate stream. That is: | |||

:<math>R_{ij} = \dfrac{m_{ij,{\rm C}}}{m_{ij,{\rm C}} + m_{ij,{\rm T}}}, \quad R_{\rm w} = \dfrac{m_{{\rm L,C}}}{m_{{\rm L,C}} + m_{{\rm L,T}}}</math> | |||

where <math>R_{ij}</math> is the recovery to concentrate of particles of size fraction <math>i</math> and floatability component type <math>j</math> (frac). | |||

</hide> | |||

== Excel == | == Excel == | ||

The dynamic Savassi flotation model is not implemented in Excel for practical purposes. Excel is not a convenient platform for dynamic simulation and SysCAD (or similar) is preferred. | |||

== SysCAD == | == SysCAD == | ||

{{ | The sections and variable names used in the SysCAD interface are described in detail in the following tables. | ||

{{SysCAD (Page, Flotation, DLL*Flotation)|method=1}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, Cell)|method=1}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, Connect)}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, CellScaleUp)}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, Froth)}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, Entrainment)}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, Floatability)}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, CZ)}} | |||

{{SysCAD (Page, Flotation Cell, Savassi, CZContent)}} | |||

{{SysCAD (Page, Hydrocyclone, Partition)|ActionU=Recovery|ActionL=recovery|DestinationU=Concentrate|DestinationL=concentrate|UnitL=cell}} | |||

{{SysCAD (Page, About)}} | |||

==== Additional notes ==== | |||

{{SysCAD (Text, No PSD Splits)|gasstream=tailings}} | |||

== See also == | == See also == | ||

* [[Flotation Cell (Savassi)]] | * [[Flotation Cell (Savassi)]] | ||

== External links == | |||

* [https://help.syscad.net/Met_Dynamics_-_Flotation Met Dynamics - Flotation (help.syscad.net)] | |||

* [https://help.syscad.net/Met_Dynamic_-_Dynamic_Example_Projects#Dynamic_Flotation_Example Dynamic Flotation Example project (help.syscad.net)] | |||

== References == | == References == | ||

[[Category:SysCAD]] | [[Category:SysCAD]] | ||

[[Category:Dynamic]] | [[Category:Dynamic]] | ||

Latest revision as of 05:59, 11 June 2025

Description

This article describes a dynamic implementation of the Savassi (2005) flotation model for use in time-dependent simulations of mechanical flotation cells..[1]

The dynamic version uses the same underlying theory and structure as the steady-state Savassi flotation model. For a full description of the steady-state model, see Flotation Cell (Savassi).

Model theory

Floatability classes

Unsteady-state mass balance

Recovery by true flotation

Recovery by entrainment

Tailings discharge

Time step discretisation

Steady-state equivalence

Pulp volume

Gas hold-up

Residence time

Bubble surface area flux

Froth recovery

Entrainment

Water recovery

Water rate function

Additional dynamic simulation considerations

Froth depth and pulp level

Feed and tailings discharge height

Froth Carry Rate and Lip Loading

Cell overflow

Recovery

Excel

The dynamic Savassi flotation model is not implemented in Excel for practical purposes. Excel is not a convenient platform for dynamic simulation and SysCAD (or similar) is preferred.

SysCAD

The sections and variable names used in the SysCAD interface are described in detail in the following tables.

MD_Flotation page

The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here.

If this field is blank, then SysCAD will display the unit class ID. |

| Requirements | ||

| On | CheckBox | This enables the unit. If this box is not checked, then the MassFracToCon option appears below. |

| MassFracToCon | Input | Only appears if the On field above is not checked. Specifies the fraction of feed mass that reports to the concentrate stream when the model is off. |

| Method | User defined | The recovery to concentrate for each size interval is defined by the user. Different values can be used for different solids. |

| Savassi | The Savassi model is used to determine the recovery of solids and liquids to concentrate. | |

| Options | ||

| ShowQFeed | CheckBox | QFeed and associated tab pages (eg Sp) will become visible, showing the properties of the combined feed stream. |

| ShowQCon | CheckBox | QCon and associated tab pages (eg Sp) will become visible, showing the properties of the concentrate stream. |

| ShowQTail | CheckBox | QTail and associated tab pages (eg Sp) will become visible, showing the properties of the tailings stream. |

| ShowCZContent | CheckBox | CZContent and associated tab pages (eg Sp) will become visible, showing the properties of the cell collection zone content. |

| SizeForPassingFracCalc | Input | Size fraction for % Passing calculation. The size fraction input here will be shown in the Stream Summary section. |

| FracForPassingSizeCalc | Input | Fraction passing for Size calculation. The fraction input here will be shown in the Stream Summary section. |

| Stream Summary | ||

| MassFlow / Qm | Display | The total mass flow in each stream. |

| SolidMassFlow / SQm | Display | The Solids mass flow in each stream. |

| LiquidMassFlow / LQm | Display | The Liquid mass flow in each stream. |

| VolFlow / Qv | Display | The total Volume flow in each stream. |

| Temperature / T | Display | The Temperature of each stream. |

| Density / Rho | Display | The Density of each stream. |

| SolidFrac / Sf | Display | The Solid Fraction in each stream. |

| LiquidFrac / Lf | Display | The Liquid Fraction in each stream. |

| Passing | Display | The mass fraction passing the user-specified size (in the field SizeForPassingFracCalc) in each stream. |

| Passes | Display | The user-specified (in the field FracForPassesSizeCalc) fraction of material in each stream will pass this size fraction. |

Cell page

The Cell page is used to specify the input parameters for the flotation model.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Savassi | ||

| HelpLink | Opens a link to this page using the system default web browser. Note: Internet access is required. | |

| Mode | Steady State |

|

| Dynamic | The dynamic Savassi flotation model described here is used to determine the cell contents and products. | |

| MaxSubStepSize | Input | The maximum allowed size of internal sub-steps for each SysCAD step. |

| SubStepSize | Display | The actual size of internal sub-steps for each SysCAD step. |

| SubSteps | Display | The actual number of internal sub-steps for each SysCAD step. |

| Cell | ||

| CellVolume/ VCell | Input | The total volume of the cell. |

| MechanismVolume / VMechansim | Input | Volume of the impeller mechanism in the cell. |

| CellArea / ACell | Input | Cross sectional area of the cell. |

| FrothDepth / Hf | Display | Froth depth from the top of the cell. |

| AirRate/ QAir | Input | Flow rate of air into the cell. |

| AirDensity / RhoAir | Display | Density of air. |

| SuperficialGasRate / Jg | Display | The superficial velocity of air through the cell. |

| EffCellPulpVolume / VEffective | Display | Volume of cell available for pulp. |

| GasHoldUp | ||

| GasHoldUpModel | No Gas Hold Up | No gas is held up in the pulp, i.e. EGas = 0 |

| User Defined | A fixed value of EGas is entered by the user, | |

| Jg Dependent | Gas hold up, EGas is computed from the value of Jg, mGas and CGas | |

| mGas | Input | Only displayed if Jg Dependent is selected. Value of slope parameter of EGas relationship. |

| CGas | Input | Only displayed if Jg Dependent is selected. Value of intercept parameter of EGas relationship. |

| EGas | Input / Display | Fraction of pulp volume occupied by gas. |

| ResidenceTime | ||

| ResTimeBasis | Feed | Residence time is calculated using the volumetric flow rate of the feed stream. |

| Tailing | Residence time is calculated using the volumetric flow rate of the tailing stream. | |

| CellResidenceTime / tau | Display | Residence time of pulp in the cell. |

| BubbleFlux | ||

| SbOption | User Defined | The user specifies a fixed value of Sb. |

| Gorain | Sb is calculated by the Gorain equation. | |

| User Equation | Sb is calculated by the an equation with user-specified parameters. | |

| Mean Diameter | Sb is calculated using the mean bubble diameter. | |

| ImpellerTipSpeed / Ns | Input | Only visible if Gorain or User Equation is selected. Speed of the impeller tip. |

| ImpellerAspectRatio / As | Input | Only visible if Gorain or User Equation is selected. Aspect ratio of the impeller. |

| UseCalculatedP80 | CheckBox | Only visible if Gorain or User Equation is selected. Specifies whether the feed stream P80 value should be used in the Sb equation. If not, P80 is user defined. |

| C | Input | Only visible if User Equation is selected. Coefficient of the user equation. |

| a | Input | Only visible if User Equation is selected. Exponent of the user equation. |

| b | Input | Only visible if User Equation is selected. Exponent of the user equation. |

| c | Input | Only visible if User Equation is selected. Exponent of the user equation. |

| d | Input | Only visible if User Equation is selected. Exponent of the user equation. |

| e | Input | Only visible if User Equation is selected. Exponent of the user equation. |

| MeanBubbleDiameter / db | Input | Only visible if Mean Diameter is selected. Sauter mean bubble diameter. |

| Sb | Display | Value of the bubble surface area flux. |

| WaterRecovery | ||

| WaterOption | Fixed % Solids | The user specifies the required concentrate solids mass fraction. |

| Solids Dependent | Water is recovered to concentrate according to the solids dependent power law function. | |

| Rate Function | Water is recovered to concentrate according to the rate function kinetic equation. | |

| User Defined | The fraction of feed water recovered to concentrate is specified by the user. | |

| QCon.SfReqd | Input | Only visible if Fixed % Solids is selected. Required concentrate solids mass fraction. |

| aW | Input | Only visible if Solids Dependent is selected. Parameter of the power law function. |

| bW | Input | Only visible if Solids Dependent is selected. Parameter of the power law function. |

| kW | Input | Only visible if Rate Function' is selected. Kinetic parameter of the rate function. |

| Rw | Input / Display | The fraction of feed water recovered to concentrate. |

| MaxFrothCarryRate | Input | The maximum allowed size of internal sub-steps for each SysCAD step. |

| FrothLimits | ||

| MaxFrothCarryRate | Input | The maximum froth carry rate. |

| FrothCarryRate | Display | The actual froth carry rate at this time step. |

| LipLength | Input | Length of the cell overflow lip. |

| MaxLipLoading | Input | Maximum lip loading of the cell. |

| LipLoading | Display | The actual lip loading of the cell at this time step. |

| MaxFrothDepthFrac | Input | Maximum froth depth as a fraction of the cell height. |

| MaxFrothDepth | Display | The maximum froth depth. |

| FrothDepth | Display | The actual froth depth. |

Connect page

The Cell page is used to specify the input parameters for the feed and tailings discharge connections.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| FeedInlet | ||

| HeightFrac | Input | The connection height of the feed inlet on the cell, expressed as a fraction of the cell height. |

| Height | Display | The actual height of the feed inlet from the bottom of the cell. |

| Head.Height | Display | The static head, the height of material above the feed inlet. |

| Head.DeltaP | Display | The static head pressure due to material above the feed inlet ( = MeasRho * g * Head.Height) |

| Pressure | Display | The calculated pressure of the feed inlet. The sum of the tank pressure and the static head. |

| MeasRho | Display | The density of the cell contents above the feed inlet. Include solids, liquids and gas hold-up. |

| TailingsOutlet | ||

| HeightFrac | Input | The connection height of the tailings outlet on the cell, expressed as a fraction of the cell height. |

| Height | Display | The actual height of the tailings outlet from the bottom of the cell. |

| Head.Height | Display | The static head, the height of material above the tailings outlet. |

| Head.DeltaP | Display | The static head pressure due to material above the tailings outlet ( = MeasRho * g * Head.Height) |

| Pressure | Display | The calculated pressure of the tailings outlet. The sum of the tank pressure and the static head. |

| MeasRho | Display | The density of the cell contents above the tailings outlet. Include solids, liquids and gas hold-up. |

| Tailings | ||

| These additional Output connection tags are also available on the SysCAD Pipe access window. Any changes made here will be updated on the pipe access window and vice-versa. | ||

| CapacityControl | Off | The maximum mass flow through the outlet will be set to unlimited amount (uncontrolled). |

| ByMassFlow | The maximum mass flow through the outlet. | |

| ByVolumeFlow | The maximum volumetric flow through the outlet. | |

| Qm.ReqdCapacity / Qm.Capacity | Input | Visible when ByMassFlow option is selected. The required pipe Capacity in mass flow. |

| Qm.MinCapacity / Qm.MinCap | Input | Visible with the ByMassFlow method. The minimum user specified flow capacity by mass. |

| Qm.MaxCapacity / Qm.MaxCap | Input | Visible with the ByMassFlow method. The maximum user specified flow capacity by mass. Enter * for unlimited flow. |

| Qv.ReqdCapacity / Qv.Capacity | Input | Visible when ByVolumeFlow option is selected. The required pipe Capacity in volumetric flow. |

| Qv.MinCapacity / Qv.MinCap | Input | Visible with the ByVolumeFlow method. The minimum user specified flow capacity by volume. |

| Qv.MaxCapacity / Qv.MaxCap | Input | Visible with the ByVolumeFlow method. The maximum user specified flow capacity by volume. Enter * for unlimited flow. |

| MeasRho | Display | The stream density used when converting between mass and volume flows. |

| OverCapacity | Spill | If more material enters the pipe then the Maximum Capacity value, then the excess material will be 'spilled' and sent to the Spills area. |

| Accept | If more material enters the pipe then the Maximum Capacity value, then the pipe must accept the excess material. | |

CellScaleUp page

This page is used to specify the cell scale up input parameters.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| CellScaleUp | ||

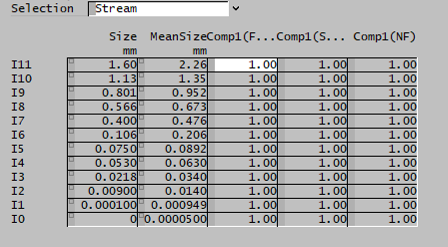

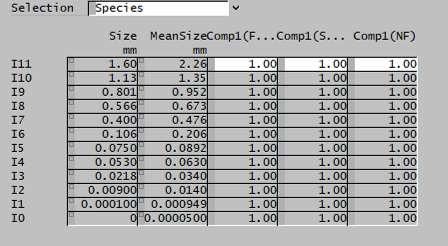

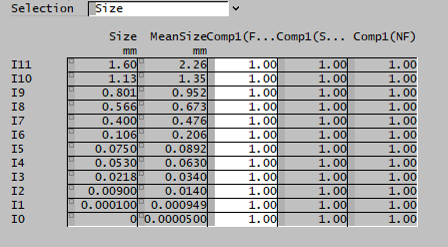

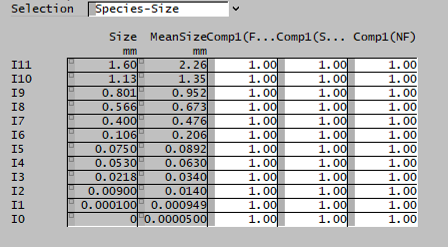

| Selection | Stream | A single CellScaleUp value is specified for all species and sizes. |

| Species | CellScaleUp values are specified per species, for all sizes of that species. | |

| Size | CellScaleUp values are specified per size interval, for all species in that interval. | |

| Species-Size | Individual CellScaleUp values are specified for each size interval of each species. | |

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| CellScaleUp | Input / Display | Cell scale-up factor (C) for each size interval, in each solid species. |

Froth page

This page is used to specify the froth recovery input parameters.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Froth | ||

| Method | User Defined | The user specifies fractional froth recovery. |

| FRT Entrain | The froth residence time model is used to determine fractional froth recovery values. The non-draining fraction is equal to calculated entrainment. | |

| FRT User Np | The froth residence time model is used to determine fractional froth recovery values. The non-draining fraction can be specified by the user. | |

| Selection | Stream | Only visible if User Defined Method is selected. A single froth recovery value is specified for all species and sizes. |

| Species | Only visible if User Defined Method is selected. Froth recovery values are specified per species, for all sizes of that species. | |

| Size | Only visible if User Defined Method is selected. Froth recovery values are specified per size interval, for all species in that interval. | |

| Species-Size | Only visible if User Defined Method is selected. Individual froth recovery values are specified for each size interval of each species. | |

| FrothVoidage / Efroth | Input | Only visible if FRT Entrain or FRT User Np methods are selected. Volumetric fraction of void space in the froth. |

| FrothResTimeBasis | Air | Only visible if FRT Entrain or FRT User Np methods are selected. Froth residence time is determined based on the superficial gas velocity (Jg). |

| Slurry | Only visible if FRT Entrain or FRT User Np methods are selected. Froth residence time is determined based on the volumetric flow rate of concentrate. | |

| FrothResidenceTime / FRT | Input / Display | Only visible if FRT Entrain or FRT User Np methods are selected. Residence time in froth. |

| DetachRateConst / Beta | Input | Only visible if FRT Entrain or FRT User Np methods are selected. Detachment rate constant per solid species. |

| NonDrainingFrac / Np | Input | Only visible if FRT Entrain or FRT User Np methods are selected. Non-draining fraction per solid species. |

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| FrothRecovery | Input / Display | Fractional recovery in froth (Rf) for each size interval, in each solid species. |

Entrainment page

This page is used to specify the entrainment input parameters.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Entrainment | ||

| Method | No Entrainment. | No entrainment, all values of ENTp are zero. |

| User Defined | The user specifies fractional recovery by entrainment. | |

| Hyperbolic | The Hyperbolic model is used to determine fractional recovery by entrainment values. | |

| FRT Dependent | The froth residence time approach is used to determine fractional recovery by entrainment values. | |

| Selection | Stream | Only visible if User Defined Method is selected. A single recovery by entrainment value is specified for all species and sizes. |

| Species | Only visible if User Defined Method is selected. Recovery by entrainment values are specified per species, for all sizes of that species. | |

| Size | Only visible if User Defined Method is selected. Recovery by entrainment values are specified per size interval, for all species in that interval. | |

| Species-Size | Only visible if User Defined Method is selected. Individual recovery by entrainment values are specified for each size interval of each species. | |

| E20 | Input | Only visible if Hyperbolic Method is selected. Parameter of the Hyperbolic entrainment equation. |

| DrainageParameter / Delta | Input | Only visible if Hyperbolic Method is selected. Parameter of the Hyperbolic entrainment equation. |

| FrothVoidage / Efroth | Input / Display | Only visible if FRT Dependent Method is selected. Volumetric fraction of void space in the froth.

Equal to the FrothVoidage input on the Froth page if the Froth Residence Time froth recovery method is selected, otherwise a user defined value. |

| FrothResTimeBasis | Air | Only visible if FRT Dependent Method is selected. Froth residence time for recovery by entrainment is determined based on the superficial gas velocity (Jg). |

| Slurry | Only visible if FRT Dependent Method is selected. Froth residence time for recovery by entrainment is determined based on the volumetric flow rate of concentrate. | |

| FrothResidenceTime / FRT | Input / Display | Only visible if FRT Dependent Method is selected. Residence time in froth for recovery by entrainment determination.

May be different to FrothResidenceTime on Froth page if different FrothResTimeBasis (Air/Slurry) is selected for each. |

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| DrainageFactor | Input | Only visible if FRT Dependent Method is selected. Drainage factors ([math]\displaystyle{ \omega }[/math]) for the FRT entrainment equation, for each size interval. |

| Entrainment | Input / Display | Recovery by entrainment (ENTp) values for each size interval, in each solid species. |

Floatability page

This page is used to specify the floatability input parameters.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Floatability | ||

| Selection | Stream | A single floatability value is specified for all species and sizes. |

| Species | Floatability values are specified per species, for all sizes of that species. | |

| Size | Floatability values are specified per size interval, for all species in that interval. | |

| Species-Size | Individual floatability values are specified for each size interval of each species. | |

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| Floatability | Input | Floatability parameters for each size interval, in each solid species. |

CZ page

This page displays information about the solids and liquids that currently comprise the cell collection zone contents.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| CZ | ||

| PulpVolumeMax / VtMax | Input / Display | The maximum volume of pulp the cell can contain before overflow. Includes gas hold-up. |

| PulpVolume / Vt | Display | The actual volume of pulp in the cell. Includes gas hold-up. |

| CellHeight | Display | Height of the cell from the bottom to the lip. |

| PulpHeight | Display | The current pulp height in the cell. Includes gas hold-up. |

| PulpLevel | Display | The current pulp height in the cell as a fraction of cell height. Includes gas hold-up. |

| Content | ||

| SolidMass / SMt | Display | The mass of solids with the SysCAD size distribution property currently in the cell. |

| LiquidMass / LMt | Display | The mass of liquids currently in the cell. |

| Size | Display | Size of each interval in internal mesh series. |

| MeanSize | Display | Geometric mean size of each interval in internal mesh series. |

| Content | Display | The mass of solids with the SysCAD size distribution property currently in the cell, by size and species. |

CZContent, Sp, Ec, Sz and MSz pages

These pages display the standard SysCAD Material Content, Species Content and Size pages for the current collection zone content.

Recovery page

The Recovery page is used to display (or specify) the recovery by species/component/element/individual phase and size values.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Recovery | ||

| Method | Model / User | Select model-calculated or user-defined recovery to separate each solids species type. |

| Density | Display | Density of each solid species. |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series.

|

| All (All column) | Display |

|

| Recovery | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per species) | Display |

|

| CmpRecovery | ||

| Components | Hides or shows component recovery table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| CmpRecovery | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per component) | Display |

|

| EleRecovery | ||

| Elements | Hides or shows element recovery table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| EleRecovery | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per element) | Display |

|

| IPhRecovery | ||

| IPhases | Hides or shows individual phases recovery table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| IPhRecovery | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per individual phase) | Display |

|

About page

This page is provides product and licensing information about the Met Dynamics Models SysCAD Add-On.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| About | ||

| HelpLink | Opens a link to the Installation and Licensing page using the system default web browser. Note: Internet access is required. | |

| Information | Copies Product and License information to the Windows clipboard. | |

| Product | ||

| Name | Display | Met Dynamics software product name |

| Version | Display | Met Dynamics software product version number. |

| BuildDate | Display | Build date and time of the Met Dynamics Models SysCAD Add-On. |

| License | ||

| File | This is used to locate a Met Dynamics software license file. | |

| Location | Display | Type of Met Dynamics software license or file name and path of license file. |

| SiteCode | Display | Unique machine identifier for license authorisation. |

| ReqdAuth | Display | Authorisation level required, MD-SysCAD Full or MD-SysCAD Runtime. |

| Status | Display | License status, LICENSE_OK indicates a valid license, other messages report licensing errors. |

| IssuedTo | Display | Only visible if Met Dynamics license file is used. Name of organisation/seat the license is authorised to. |

| ExpiryDate | Display | Only visible if Met Dynamics license file is used. License expiry date. |

| DaysLeft | Display | Only visible if Met Dynamics license file is used. Days left before the license expires. |

Additional notes

- Solid species that do not possess a particle size distribution property are split according to the overall mass split of the default particle size distribution species selected in the SysCAD Project Configuration.

- If the default particle size distribution species is not present in the unit feed, the overall split of all other species with particle size distributions combined is used, as determined by the model.

- Gas phase species report directly to the tailings stream without split.

See also

External links

References

- ↑ Savassi, O.N., 2005. A compartment model for the mass transfer inside a conventional flotation cell. International Journal of Mineral Processing, 77(2), pp.65-79.