Description

This article describes a methodology for estimating the solids mass split and recovery of multiple assayed components from a process step with any number of product streams.

Model theory

This content is available to registered users. Please log in to view. This content is available to registered users. Please log in to view.

|

Unweighted estimates

Weighted estimates

Additional notes

Absolute and relative standard deviations

Component assay magnitude

Excel

The n-product formula may be invoked from the Excel formula bar with the following function call:

=mdMassBal_nProductFormula(Assays as Range, Optional AbsSD as Range, Optional Transposed as Boolean = False)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The input parameters and calculation results are defined below in matrix notation, along with example images showing the selection of the same cells and arrays in the Excel interface.

Default

The following default arrangement of inputs and results ranges apply when the formula argument Transposed is false or omitted:

- [math]\displaystyle{

\begin{align}

\mathit{Assay} & =

\begin{bmatrix}

f_1 & \cdots & f_m\\

p_{11} & \cdots & p_{m1}\\

\vdots & \ddots & \vdots\\

p_{1n} & \cdots & p_{mn}\\

\end{bmatrix}\\

\\

\mathit{AbsSD} & =

\begin{bmatrix}

\sigma_{\rm f1} & \cdots & \sigma_{{\rm f}m}\\

\sigma_{11} & \cdots & \sigma_{m1}\\

\vdots & \ddots & \vdots\\

\sigma_{1n} & \cdots & \sigma_{mn}\\

\end{bmatrix}\\

\end{align} }[/math]

|

- [math]\displaystyle{

\begin{align}

\mathit{mdMassBal\_nProductFormula} & =

\begin{bmatrix}

\beta_{\rm f}\text{ (frac)} & \hat{f}_1\text{ (frac)} & \cdots & \hat{f}_m\text{ (frac)}\\

\beta_1\text{ (frac)} & R_{11}\text{ (frac)} & \cdots & R_{m1}\text{ (frac)}\\

\vdots & \vdots & \ddots & \vdots\\

\beta_n\text{ (frac)} & R_{1n}\text{ (frac)} & \cdots & R_{mn}\text{ (frac)}\\

\end{bmatrix}

\end{align}

}[/math]

|

|

where:

- [math]\displaystyle{ \beta_{\rm f} }[/math] is total mass fraction of solids in the feed (frac), i.e. [math]\displaystyle{ \beta_{\rm f} = \sum\nolimits_i^n {\beta_i} = 1 }[/math]

- the unweighted sum of squares approach is used if [math]\displaystyle{ AbsSD }[/math] is omitted.

|

|

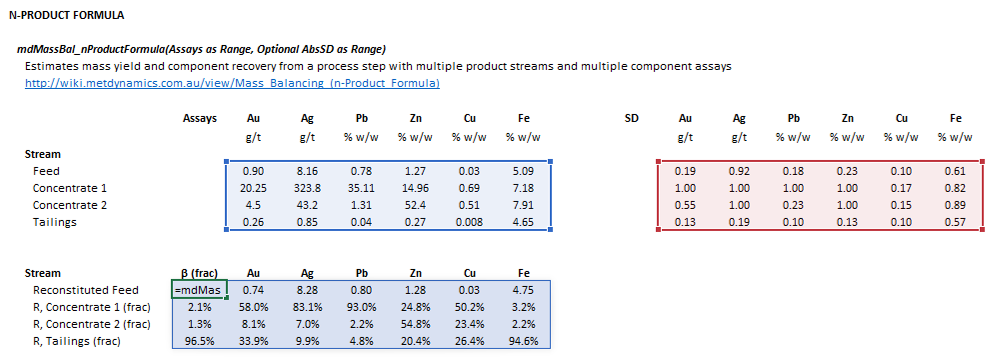

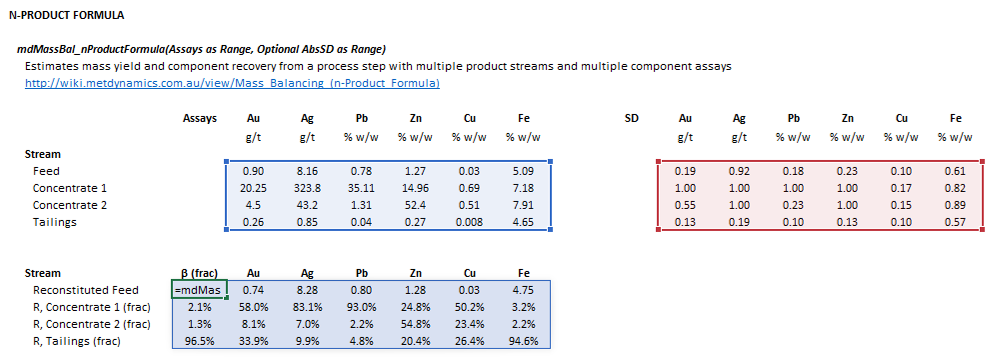

Figure 1. Example showing the selection of the Assay (blue frame), AbsSD (red frame), and Results (light blue frame) arrays in Excel.

|

Transposed

The following arrangement of inputs and results ranges apply when the formula argument Transposed is true:

- [math]\displaystyle{

\begin{align}

\mathit{Assay} & =

\begin{bmatrix}

f_1 & p_{11} & \cdots & p_{1n}\\

\vdots & \vdots & \ddots\\

f_m & p_{1m} & \cdots & p_{mn}\\

\end{bmatrix}\\

\\

\mathit{AbsSD} & =

\begin{bmatrix}

\sigma_{{\rm f} 1} & \sigma_{11} & \cdots & \sigma_{1n}\\

\vdots & \vdots & \ddots\\

\sigma_{{\rm f} m} & \sigma_{1m} & \cdots & \sigma_{mn}\\

\end{bmatrix}\\

\end{align} }[/math]

|

- [math]\displaystyle{

\begin{align}

\mathit{mdMassBal\_nProductFormula} & =

\begin{bmatrix}

\beta_{\rm f}\text{ (frac)} & \beta_1\text{ (frac)} & \cdots & \beta_n\text{ (frac)}\\

\hat{f}_1\text{ (frac)} & R_{11}\text{ (frac)} & \cdots & R_{1n}\text{ (frac)}\\

\vdots & \vdots & \ddots & \vdots\\

\hat{f}_m\text{ (frac)} & R_{m1}\text{ (frac)} & \cdots & R_{mn}\text{ (frac)}\\

\end{bmatrix}

\end{align}

}[/math]

|

|

|

|

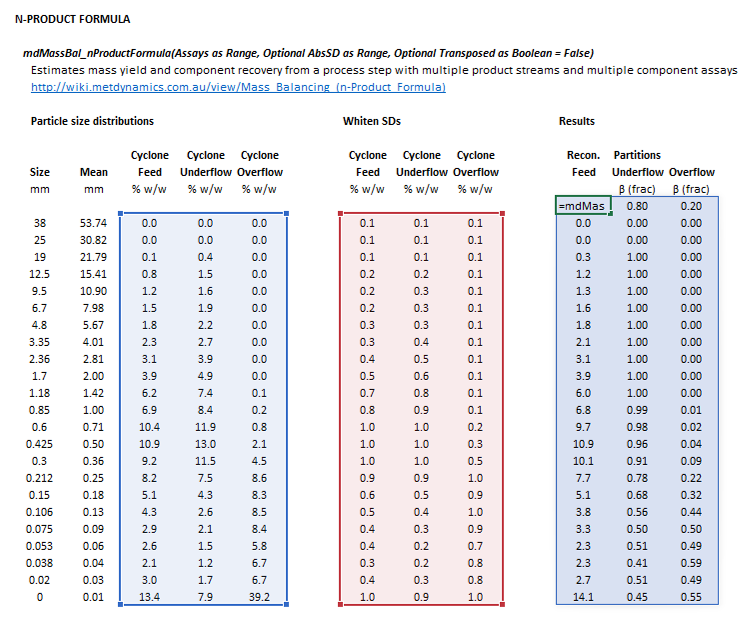

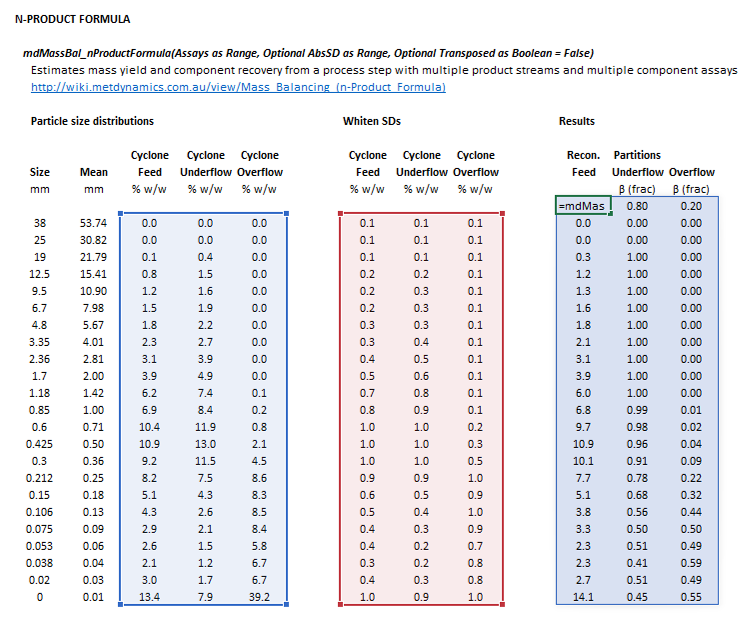

Figure 2. Example showing the selection of the Assay (blue frame), AbsSD (red frame), and Results (light blue frame) arrays in Excel when [math]\displaystyle{ \mathit{Transposed} = \mathrm{True} }[/math].

|

See also

References