imported>Scott.Munro |

imported>Scott.Munro |

| Line 5: |

Line 5: |

| == Model theory == | | == Model theory == |

|

| |

|

| | {{Restricted content}} |

| | |

| | <hide> |

| === Shi method === | | === Shi method === |

|

| |

|

| Line 196: |

Line 199: |

|

| |

|

| Arbiter's relations were developed from a limited database of five mills, the largest of which was 5.3 m diameter x 6.4 m length. | | Arbiter's relations were developed from a limited database of five mills, the largest of which was 5.3 m diameter x 6.4 m length. |

| | </hide> |

|

| |

|

| == Excel == | | == Excel == |

Revision as of 11:21, 4 December 2024

Description

This article describes several methods for estimating the maximum volumetric flow capacity of an overflow ball mill, including the Shi (2016) and Arbiter (1991) approaches.[1][2]

Model theory

This content is available to registered users. Please log in to view. This content is available to registered users. Please log in to view.

|

Excel

Shi method

The Shi overflow discharge ball mill overfilling model may be invoked from the Excel formula bar with the following function call:

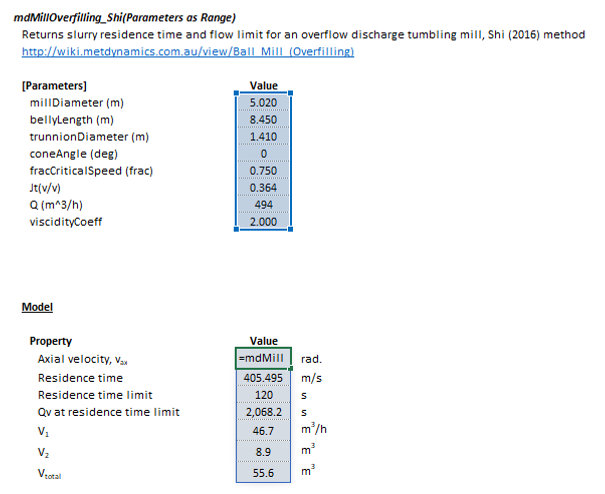

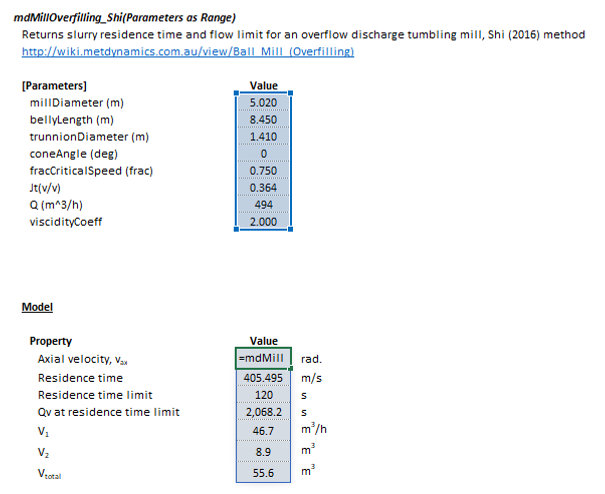

=mdMillOverfilling_Shi(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

- [math]\displaystyle{ Parameters=

\begin{bmatrix}

D_{\rm m}\text{ (m)}\\

L\text{ (m)}\\

R_{\rm t}\text{ (m)}\\

\alpha_{c}\text{ (degrees)}\\

\phi\text{ (frac)}\\

J_{\rm t}\text{ (v/v)}\\

Q\text{ (m}^{3}\text{/h)}\\

k_{\mu}\\

\end{bmatrix},\;\;\;\;\;\;

mdMillOverfilling\_Shi=

\begin{bmatrix}

v_{\rm ax}\text{ (m/s)}\\

t_{\rm Res}\text{ (s)}\\

t_{\rm Limit}\text{ (s)}\\

Q_{\rm Max}\text{ (m}^{3}\text{/h)}\\

V_{1}\text{ (m}^{3}\text{)}\\

V_{2}\text{ (m}^{3}\text{)}\\

V_{\rm total}\text{ (m}^{3}\text{)}\\

\end{bmatrix}\;\;\;\;\;\;

}[/math]

|

Figure 3. Example showing the selection of the Parameters (blue frame), and Results (light blue frame) arrays in Excel. |

Arbiter method

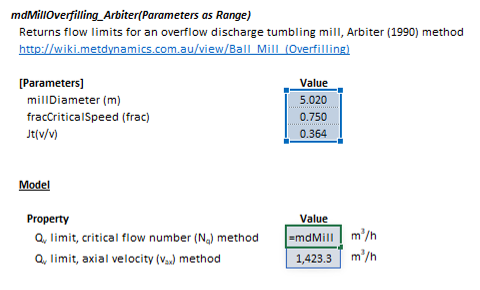

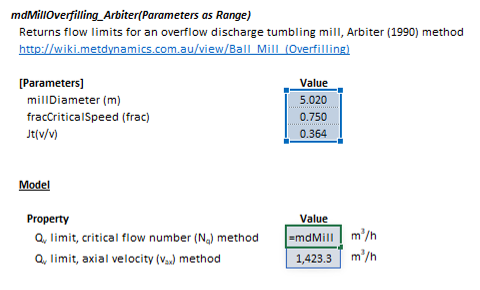

The Arbiter overflow discharge ball mill overfilling model may be invoked from the Excel formula bar with the following function call:

=mdMillOverfilling_Arbiter(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

- [math]\displaystyle{ Parameters=

\begin{bmatrix}

D_{\rm m}\text{ (m)}\\

\phi\text{ (frac)}\\

J_{\rm t}\text{ (v/v)}\\

\end{bmatrix},\;\;\;\;\;\;

mdMillOverfilling\_Arbiter=

\begin{bmatrix}

Q_{N_{\rm q}}\text{ (m}^{3}\text{/h)}\\

\end{bmatrix}\;\;\;\;\;\;

}[/math]

|

Figure 4. Example showing the selection of the Parameters (blue frame), and Results (light blue frame) arrays in Excel. |

SysCAD

The Ball Mill Overfilling Indicator model is an optional calculation for tumbling mill units. If selected, the input and display parameters below are shown.

| Tag (Long/Short)

|

Input / Display

|

Description/Calculated Variables/Options

|

| Overfilling

|

| HelpLink

|

|

Opens a link to this page using the system default web browser. Note: Internet access is required.

|

| Shi

|

| MillDiameter

|

Input/Display

|

Diameter of the mill (inside liners).

|

| BellyLength

|

Input/Display

|

Length of the cylindrical section (belly) of the mill (inside liners).

|

| TrunnionDiameter

|

Input/Display

|

Diameter of the trunnion (inside liners).

|

| ConeAngle

|

Input/Display

|

Angular displacement of the cone surface from the vertical direction.

|

| FracCS

|

Input/Display

|

Fraction critical speed of the mill.

|

| Jt

|

Input/Display

|

Volumetric fraction of the mill occupied by balls and coarse rock (including voids).

|

| ViscidityCoeff

|

Input

|

Coefficient of viscidity.

|

| V1

|

Display

|

Volume of slurry below slurry pool level.

|

| V2

|

Display

|

Volume of slurry above slurry pool level.

|

| V1

|

Display

|

Total volume of slurry in charge and pool.

|

| AxialVelocity

|

Display

|

Axial velocity of slurry flow through the charge and pool.

|

| tRes

|

Display

|

Residence time of slurry in mill.

|

| tLimit

|

Display

|

Shi's suggested lower limit of residence time for mill. Based on mill diameter.

|

| Feed.SLQv

|

Display

|

Volumetric flow rate of slurry (solids + liquids) in mill feed.

|

| Feed.SLQv.Limit

|

Display

|

Estimated volumetric flow rate of slurry (solids + liquids) in mill feed at tLimit.

|

| Overfilled

|

True/False

|

Indicates if tRes is less than tLimit, i.e. mill is overfilled.

|

| Arbiter

|

| MillDiameter

|

Input/Display

|

Diameter of the mill (inside liners).

|

| FracCS

|

Input/Display

|

Fraction critical speed of the mill.

|

| Jt

|

Input/Display

|

Volumetric fraction of the mill occupied by balls and coarse rock (including voids).

|

| Feed.SLQv

|

Display

|

Volumetric flow rate of slurry (solids + liquids) in mill feed.

|

| Feed.SLQv.NqLimit

|

Display

|

Estimated volumetric flow rate of slurry (solids + liquids) at Arbiters critical flow number limit.

|

See also

References

- ↑ Shi, F., 2016. An overfilling indicator for wet overflow ball mills. Minerals Engineering, 95, pp.146-154.

- ↑ Arbiter, N., 1991. Dimensionality in ball mill dynamics. Mining, Metallurgy & Exploration, 8(2), pp.77-81.