Air Classifier (Altun): Difference between revisions

Jump to navigation

Jump to search

Scott Munro (talk | contribs) m (1 revision imported) |

imported>Scott.Munro m (Text replacement - "\mathit{DL}" to "{\rm DL}") |

||

| Line 22: | Line 22: | ||

\begin{bmatrix} | \begin{bmatrix} | ||

D\text{ (m)}\\ | D\text{ (m)}\\ | ||

\ | {\rm AF}\text{ (m}^3\text{/h)}\\ | ||

\ | {\rm RS}\text{ (m/s)}\\ | ||

k_{\alpha}\\ | k_{\alpha}\\ | ||

n_{\alpha}\\ | n_{\alpha}\\ | ||

| Line 56: | Line 56: | ||

where: | where: | ||

* <math>D</math> is the classifier chamber diameter (m) | * <math>D</math> is the classifier chamber diameter (m) | ||

* <math>\ | * <math>{\rm AF}</math> is the air flow rate (m<sup>3</sup>/h) | ||

* <math>\ | * <math>{\rm RS}</math> is rotor speed (m/s) | ||

* <math>k</math> is an equation coefficient | * <math>k</math> is an equation coefficient | ||

* <math>n</math> is an equation exponent | * <math>n</math> is an equation exponent | ||

| Line 77: | Line 77: | ||

\begin{bmatrix} | \begin{bmatrix} | ||

\ | {\rm DL}\text{ (kg/m}^3\text{)}\\ | ||

F\text{ (t/h)}\\ | F\text{ (t/h)}\\ | ||

\alpha\\ | \alpha\\ | ||

| Line 135: | Line 135: | ||

where: | where: | ||

* <math>\ | * <math>{\rm DL}</math> is the dust loading (kg/m<sup>3</sup>) | ||

* <math>F</math> is the flow rate of -36+3 µm size particles in the feed (t/h) | * <math>F</math> is the flow rate of -36+3 µm size particles in the feed (t/h) | ||

* <math>\alpha</math> is the sharpness parameter of the [[Partition (Size, Whiten-Beta)|Whiten-Beta]] efficiency curve | * <math>\alpha</math> is the sharpness parameter of the [[Partition (Size, Whiten-Beta)|Whiten-Beta]] efficiency curve | ||

Revision as of 11:46, 29 July 2023

Description

This article describes the Altun and Benzer (2014) model for air classification.[1]

Model theory

Excel

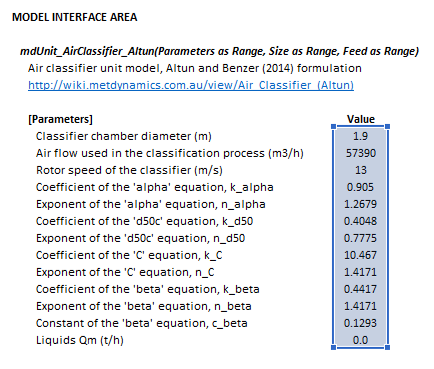

The Altun air classifier model may be invoked from the Excel formula bar with the following function call:

=mdUnit_AirClassifier_Altun(Parameters as Range, Size as Range, Feed as Range, OreSG Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

Inputs

The required inputs are defined below in matrix notation with elements corresponding to cells in Excel row ([math]\displaystyle{ i }[/math]) x column ([math]\displaystyle{ j }[/math]) format:

- [math]\displaystyle{ Parameters= \begin{bmatrix} D\text{ (m)}\\ {\rm AF}\text{ (m}^3\text{/h)}\\ {\rm RS}\text{ (m/s)}\\ k_{\alpha}\\ n_{\alpha}\\ k_{d_{50}}\\ n_{d_{50}}\\ k_{C}\\ n_{C}\\ k_{\beta}\\ n_{\beta}\\ c_{\beta}\\ (Q_{\rm M,F})_{\rm L}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; Size = \begin{bmatrix} d_{1}\text{ (mm)}\\ \vdots\\ d_p\text{ (mm)}\\ \end{bmatrix},\;\;\;\;\;\; Feed= \begin{bmatrix} (Q_{\rm M,F})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,F})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{nm}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; OreSG= \begin{bmatrix} (\rho_{\rm S})_{1}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_m\text{ (t/m}^\text{3}\text{)}\\ \end{bmatrix} }[/math]

where:

- [math]\displaystyle{ D }[/math] is the classifier chamber diameter (m)

- [math]\displaystyle{ {\rm AF} }[/math] is the air flow rate (m3/h)

- [math]\displaystyle{ {\rm RS} }[/math] is rotor speed (m/s)

- [math]\displaystyle{ k }[/math] is an equation coefficient

- [math]\displaystyle{ n }[/math] is an equation exponent

- [math]\displaystyle{ c }[/math] is an equation constant

- [math]\displaystyle{ (Q_{\rm M,F})_{\rm L} }[/math] is the mass flow rate of liquids in the feed (t/h)'

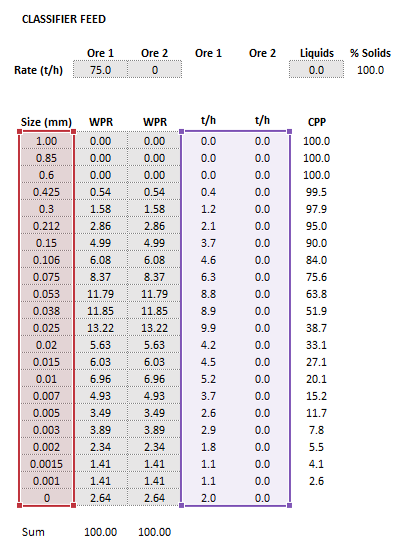

- [math]\displaystyle{ p }[/math] is the number of size intervals

- [math]\displaystyle{ m }[/math] is the number of ore types

- [math]\displaystyle{ d_i }[/math] is the size of the square mesh interval that mass is retained on (mm)

- [math]\displaystyle{ d_{i+1}\lt d_i\lt d_{i-1} }[/math], i.e. descending size order from top size ([math]\displaystyle{ d_{1} }[/math]) to sub mesh ([math]\displaystyle{ d_{p}=0 }[/math] mm)

- [math]\displaystyle{ \rho_{\rm S} }[/math] is the density of solids (t/m3)

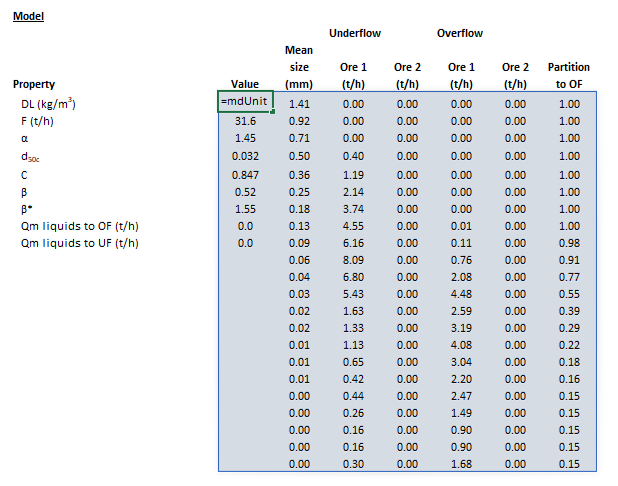

Results

The results are displayed in Excel as an array corresponding to the matrix notation below:

- [math]\displaystyle{ \mathit{mdUnit\_AirClassifier\_Altun} = \begin{bmatrix} \begin{bmatrix} {\rm DL}\text{ (kg/m}^3\text{)}\\ F\text{ (t/h)}\\ \alpha\\ d_{\rm 50c}\text{ (mm)}\\ C\text{ (frac)}\\ \beta\\ \beta^*\\ (Q_{\rm M,OF})_{\rm L}\text{ (t/h)}\\ (Q_{\rm M,UF})_{\rm L}\text{ (t/h)}\\ \end{bmatrix} \begin{array}{cccccc} \begin{bmatrix} \bar d_1\text{ (mm)}\\ \vdots\\ \bar d_n\text{ (mm)} \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,UF})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,UF})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,UF})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,UF})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,OF})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,OF})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,OF})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,OF})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (P_{\rm OF})_1\text{ (frac)}\\ \vdots\\ (P_{\rm OF})_n\text{ (frac)} \end{bmatrix} \\ \\ \\ \\ \\ \\ \\ \end{array} \end{bmatrix} }[/math]

where:

- [math]\displaystyle{ {\rm DL} }[/math] is the dust loading (kg/m3)

- [math]\displaystyle{ F }[/math] is the flow rate of -36+3 µm size particles in the feed (t/h)

- [math]\displaystyle{ \alpha }[/math] is the sharpness parameter of the Whiten-Beta efficiency curve

- [math]\displaystyle{ d_{\rm 50c} }[/math] is the cut size parameter of the Whiten-Beta efficiency curve (mm)

- [math]\displaystyle{ C }[/math] is the bypass parameter of the Whiten-Beta efficiency curve (frac)

- [math]\displaystyle{ \beta }[/math] is a fish-hook parameter of the Whiten-Beta efficiency curve

- [math]\displaystyle{ \beta^* }[/math] is a fish-hook parameter of the Whiten-Beta efficiency curve

- [math]\displaystyle{ (Q_{\rm M,OF})_{\rm L} }[/math] is the mass flow rate of liquids to the overflow stream (t/h)

- [math]\displaystyle{ (Q_{\rm M,UF})_{\rm L} }[/math] is the mass flow rate of liquids to the underflow stream (t/h)

- [math]\displaystyle{ P_{\rm OF} }[/math] is the partition fraction to overflow (frac)

Example

The images below show the selection of input arrays and output results in the Excel interface.

SysCAD

References

- ↑ Altun, O. and Benzer, H., 2014. Selection and mathematical modelling of high efficiency air classifiers. Powder Technology, 264, pp.1-8.