Jig (King): Difference between revisions

Scott Munro (talk | contribs) m (1 revision imported) |

imported>Scott.Munro mNo edit summary |

||

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Description == | == Description == | ||

This article describes a model for the equilibrium stratification of particles in gravity concentration devices such as jigs. The original model formulation is outlined by King (2012) and extensions for particle size effects are | This article describes a model for the equilibrium stratification of particles in autogenous media gravity concentration devices such as jigs. The original model formulation is outlined by King (2012) and extensions for particle size effects are proposed by Rao (2007).{{King (2012)}}{{Rao (2007)}} | ||

== Model theory == | == Model theory == | ||

{{Restricted content}} | |||

<hide> | |||

{{Under construction|section}} | {{Under construction|section}} | ||

</hide> | |||

== Excel == | == Excel == | ||

{{ | The King stratification jig model may be invoked from the Excel formula bar with the following function call: | ||

<syntaxhighlight lang="vb">=mdUnit_Jig_King(Parameters as Range, Size as Range, Density As Range, Feed as Range, Optional returnConcProfile As Boolean = False)</syntaxhighlight> | |||

{{Excel (Text, Help, No Arguments)}} | |||

=== Inputs === | |||

{{Excel (Text, Inputs)}} | |||

:<math>Parameters= | |||

\begin{bmatrix} | |||

\text{Method}\\ | |||

A\text{ (-)}\\ | |||

b\text{ (-)}\\ | |||

\kappa\text{ (-)}\\ | |||

p\text{ (-)}\\ | |||

h_{\rm s}\text{ (m/m)}\\ | |||

(Q_{\rm M,F})_{\rm L}\text{ (t/h)}\\ | |||

\end{bmatrix},\;\;\;\;\;\; | |||

Size = \begin{bmatrix} | |||

d_{1}\text{ (mm)}\\ | |||

\vdots\\ | |||

d_n\text{ (mm)}\\ | |||

\end{bmatrix},\;\;\;\;\;\; | |||

Density = \begin{bmatrix} | |||

(\rho_{\rm S})_{11}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_{1m}\text{ (t/m}^\text{3}\text{)}\\ | |||

\vdots & \ddots & \vdots\\ | |||

(\rho_{\rm S})_{n1}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_{nm}\text{ (t/m}^\text{3}\text{)}\\ | |||

\end{bmatrix}\;\;\; \text{or}\;\;\; | |||

\begin{bmatrix} | |||

(\rho_{\rm S})_{1}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_{m}\text{ (t/m}^\text{3}\text{)}\\ | |||

\end{bmatrix},\;\;\;\;\;\; | |||

</math> | |||

:<math> | |||

Feed= \begin{bmatrix} | |||

(Q_{\rm M,F})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{1m}\text{ (t/h)}\\ | |||

\vdots & \ddots & \vdots\\ | |||

(Q_{\rm M,F})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{nm}\text{ (t/h)}\\ | |||

\end{bmatrix},\;\;\;\;\;\; | |||

\mathit{returnConcProfile} = \big [ \text{(True / False)} \big ] | |||

</math> | |||

where: | |||

* <math>\text{Method}</math> indicates whether the jig is in a batch or continuous configuration, ''(0 = Batch, 1 = Continuous)'' | |||

* <math>A</math> is the particle size coefficient (-) | |||

* <math>b</math> is the particle size exponent (-) | |||

* <math>\kappa</math> is the velocity profile shape parameter (-) | |||

* <math>p</math> is the number of bed height increments (-) | |||

* <math>h_{\rm s}</math> is the relative bed cut height (m/m) | |||

* <math>Q_{\rm M,F}</math> is feed solids mass flow rate by size and ore type (t/h) | |||

* <math>(Q_{\rm M,F})_{\rm L}</math> is the mass flow feed rate of liquids into the jig (t/h) | |||

* <math>\mathit{returnConcProfile}</math> indicates whether to return the full volume concentration of solids by density class, size and bed height, ''(True/False'') | |||

Note that <math>\mathit{Density}</math> can be specified on a per particle size per ore type basis, or with a singular value for all particle sizes of a given ore type. | |||

=== Results === | |||

The results are displayed in Excel as an array corresponding to the matrix notation below: | |||

:<math> | |||

\mathit{mdUnit\_Jig\_King} = | |||

\begin{bmatrix} | |||

\begin{bmatrix} | |||

\text{Iterations}\\ | |||

\text{Iteration error}\\ | |||

R_{\rm s}\text{ (frac)}\\ | |||

R_{\rm f}\text{ (frac)}\\ | |||

\rho_{50}\text{ (t/m}^3\text{)}\\ | |||

E_{\rm p}\text{ (t/m}^3\text{)}\\ | |||

I\text{ (-)}\\ | |||

(Q_{\rm M,C})_{\rm L}\text{ (t/h)}\\ | |||

(Q_{\rm M,T})_{\rm L}\text{ (t/h)}\\ | |||

\end{bmatrix} | |||

\begin{array}{cccccc} | |||

\begin{bmatrix} | |||

\bar d_1\text{ (mm)}\\ | |||

\vdots\\ | |||

\bar d_n\text{ (mm)} | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

(Q_{\rm M,C})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,C})_{1m}\text{ (t/h)}\\ | |||

\vdots & \ddots & \vdots\\ | |||

(Q_{\rm M,C})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,C})_{nm}\text{ (t/h)}\\ | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

(Q_{\rm M,T})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,T})_{1m}\text{ (t/h)}\\ | |||

\vdots & \ddots & \vdots\\ | |||

(Q_{\rm M,T})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,T})_{nm}\text{ (t/h)}\\ | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

(P_{\rm C})_{11}\text{ (frac)} & \dots & (P_{\rm C})_{1m}\text{ (frac)}\\ | |||

\vdots & \ddots & \vdots\\ | |||

(P_{\rm C})_{n1}\text{ (frac)} & \dots & (P_{\rm C})_{nm}\text{ (frac)}\\ | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

(P_{\rm C})_1\text{ (frac)}\\ | |||

\vdots\\ | |||

(P_{\rm C})_n\text{ (frac)}\\ | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

(P_{\rm C})_1\text{ (frac)} & \dots & (P_{\rm C})_m\text{ (frac)}\\ | |||

\end{bmatrix} | |||

\begin{bmatrix} | |||

(\rho_{50})_1\text{ (t/m}^3\text{)}\\ | |||

\vdots\\ | |||

(\rho_{50})_n\text{ (t/m}^3\text{)}\\ | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

(E_{\rm p})_1\text{ (t/m}^3\text{)}\\ | |||

\vdots\\ | |||

(E_{\rm p})_n\text{ (t/m}^3\text{)}\\ | |||

\end{bmatrix} | |||

& | |||

\begin{bmatrix} | |||

\begin{bmatrix} | |||

C_{111}\text{ (v/v)} & \cdots & C_{1m1}\text{ (v/v)}\\ | |||

\end{bmatrix} | |||

& \cdots & | |||

\begin{bmatrix} | |||

C_{111}\text{ (v/v)} & \cdots & C_{nm1}\text{ (v/v)}\\ | |||

\end{bmatrix}\\ | |||

\vdots & \ddots & \vdots\\ | |||

\begin{bmatrix} | |||

C_{11p}\text{ (v/v)} & \cdots & C_{1mp}\text{ (v/v)}\\ | |||

\end{bmatrix} | |||

& \cdots & | |||

\begin{bmatrix} | |||

C_{11p}\text{ (v/v)} & \cdots & C_{nmp}\text{ (v/v)}\\ | |||

\end{bmatrix}\\ | |||

\end{bmatrix}^*\\ | |||

\\ | |||

\\ | |||

\\ | |||

\\ | |||

\\ | |||

\\ | |||

\end{array} | |||

\end{bmatrix} | |||

</math> | |||

where: | |||

* <math>\text{Iterations}</math> is the total number of internal iterations required across all stages to reach the equilibrium stratification condition | |||

* <math>\text{Iteration error}</math> is the maximum convergence error of the equilibrium stratification solutions across all stages | |||

* <math>R_{\rm s}</math> is the overall recovery of solids to the concentrate (heavy) stream (frac) | |||

* <math>R_{\rm f}</math> is the estimated recovery of water to the concentrate stream (frac) | |||

* <math>(Q_{\rm M,C})_{\rm L}</math> is the mass flow rate of liquids to the concentrate stream (t/h) | |||

* <math>(Q_{\rm M,T})_{\rm L}</math> is the mass flow rate of liquids to the tailing (light) stream (t/h) | |||

* <math>Q_{\rm M,C}</math> is mass flow rate of solids to the concentrate stream (t/h) | |||

* <math>Q_{\rm M,T}</math> is mass flow rate of solids to the tailing stream (t/h) | |||

* <math>P_{\rm C}</math> is partition fraction of feed solids to the concentrate stream (frac) | |||

* <math>C_{ijk}</math> is the volume concentration of solids of density class <math>i</math> and size interval <math>j</math> at height increment <math>k</math> in the equilibrium-stratified bed (v/v) | |||

* <math>^*</math> indicates optional results returned if <math>\mathit{returnConcProfile} = \text{True}</math> | |||

=== Example === | |||

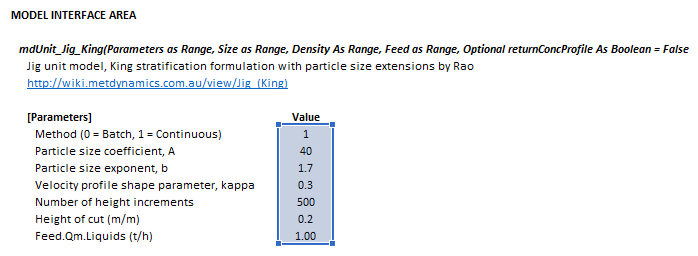

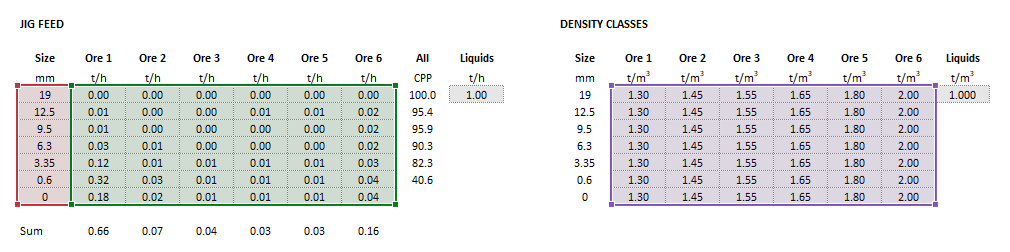

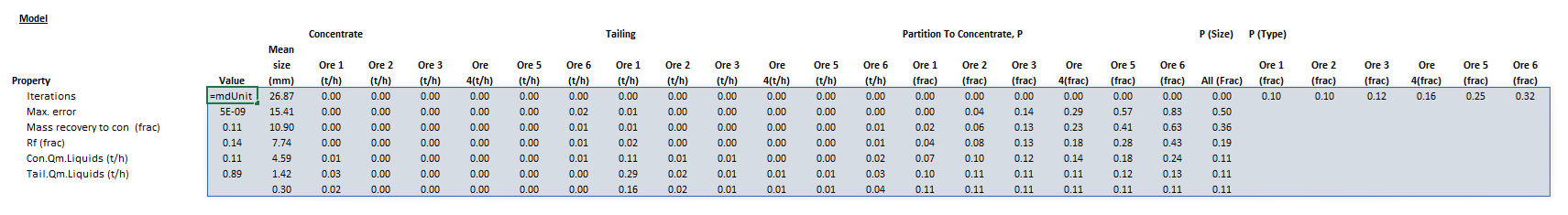

The images below show the selection of input arrays and output results in the Excel interface. | |||

{| | |||

|- style="vertical-align:top;" | |||

| [[File:JigKing1.png|left|frame|Figure 1. Example showing the selection of the '''Parameters''' (blue frame) array in Excel.]] || [[File:JigKing2.png|left|frame|Figure 2. Example showing the selection of the '''Size''' (red frame), '''Density''' (purple frame) and '''Feed''' (green frame) arrays in Excel.]] || | |||

|- style="vertical-align:top;" | |||

|colspan="2"| [[File:JigKing3.png|left|frame|Figure 3. Example showing the outline of the '''Results''' (light blue frame) array in Excel. This exampple excludes the concentration profile data (<math>\mathit{returnConcProfile} = \text{False}</math>)]] | |||

|} | |||

== SysCAD == | == SysCAD == | ||

{{ | The sections and variable names used in the SysCAD interface are described in detail in the following tables. | ||

Note that a '''Con''' and '''Partition''' page is provided for each connected concentrate discharge stream. | |||

{{SysCAD (Page, Gravity Concentrator, DLL*GravityConcentrator)}} | |||

==== Con page ==== | |||

The Con page is used to specify the required model method and associated input parameters. | |||

{{SysCAD (Text, Table Header)}} | |||

{{SysCAD (Text, Gravity Concentrator, Con)}} | |||

{{SysCAD (Text, Help Link)}} | |||

|- | |||

! colspan="3" style="text-align:left;" |''Parameters'' | |||

|- style="vertical-align:top;" | |||

|rowspan="2" | Method | |||

|Batch | |||

|The jig is operated as a batch or plug flow device. | |||

|- style="vertical-align:top;" | |||

|Continuous | |||

|The jig is operated as a continuous device. | |||

|- | |||

|ParticleSizeCoeff / A | |||

|Input | |||

|Coefficient of the particle size power law equation. | |||

|- | |||

|ParticleSizeExp / b | |||

|Input | |||

|Exponent of the particle size power law equation. | |||

|- | |||

|Kappa | |||

|Input | |||

|Velocity profile shape parameter. | |||

|- | |||

|NumHeightInc / hInc | |||

|Input | |||

|The number of height increments subdividing the bed. | |||

|- | |||

|CutHeight / hs | |||

|Input | |||

|The relative bed cut height. | |||

{{SysCAD (Text, Gravity Concentrator, Liquids)|method=1}} | |||

|- | |||

! colspan="3" style="text-align:left;" |''Results'' | |||

|- | |||

|Iterations | |||

|style="background: #eaecf0" |Display | |||

|Shows the number of internal model iterations (per SysCAD step) required to converge the stratification model. | |||

|- | |||

|MaxError | |||

|style="background: #eaecf0" |Display | |||

|Shows the quantity of the convergence error between internal model iterations. | |||

|- | |||

|CutDensity / Rho50 | |||

|style="background: #eaecf0" | Display | |||

|Unsized cut density (Rho50). | |||

|- | |||

|EcartProbable / Ep | |||

|style="background: #eaecf0" | Display | |||

|Unsized Ecart Probable (Ep). | |||

|- | |||

|Imperfection / I | |||

|style="background: #eaecf0" | Display | |||

|Unsized partition Imperfection (I). | |||

|} | |||

{{SysCAD (Page, Hydrocyclone, Partition)|ActionU=Partition|ActionL=partition|DestinationU=Concentrate|DestinationL=concentrate|UnitL=gravity concentrator|GravityMetrics=false|Rho50Ep=Display}} | |||

{{SysCAD (Page, About)}} | |||

==== Additional notes ==== | |||

{{SysCAD (Text, No PSD Splits)|gasstream=tail}} | |||

== References == | == References == | ||

Latest revision as of 08:36, 12 June 2025

Description

This article describes a model for the equilibrium stratification of particles in autogenous media gravity concentration devices such as jigs. The original model formulation is outlined by King (2012) and extensions for particle size effects are proposed by Rao (2007).[1][2]

Model theory

Excel

The King stratification jig model may be invoked from the Excel formula bar with the following function call:

=mdUnit_Jig_King(Parameters as Range, Size as Range, Density As Range, Feed as Range, Optional returnConcProfile As Boolean = False)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

Inputs

The required inputs are defined below in matrix notation with elements corresponding to cells in Excel row ([math]\displaystyle{ i }[/math]) x column ([math]\displaystyle{ j }[/math]) format:

- [math]\displaystyle{ Parameters= \begin{bmatrix} \text{Method}\\ A\text{ (-)}\\ b\text{ (-)}\\ \kappa\text{ (-)}\\ p\text{ (-)}\\ h_{\rm s}\text{ (m/m)}\\ (Q_{\rm M,F})_{\rm L}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; Size = \begin{bmatrix} d_{1}\text{ (mm)}\\ \vdots\\ d_n\text{ (mm)}\\ \end{bmatrix},\;\;\;\;\;\; Density = \begin{bmatrix} (\rho_{\rm S})_{11}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_{1m}\text{ (t/m}^\text{3}\text{)}\\ \vdots & \ddots & \vdots\\ (\rho_{\rm S})_{n1}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_{nm}\text{ (t/m}^\text{3}\text{)}\\ \end{bmatrix}\;\;\; \text{or}\;\;\; \begin{bmatrix} (\rho_{\rm S})_{1}\text{ (t/m}^\text{3}\text{)} & \dots & (\rho_{\rm S})_{m}\text{ (t/m}^\text{3}\text{)}\\ \end{bmatrix},\;\;\;\;\;\; }[/math]

- [math]\displaystyle{ Feed= \begin{bmatrix} (Q_{\rm M,F})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,F})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{nm}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{returnConcProfile} = \big [ \text{(True / False)} \big ] }[/math]

where:

- [math]\displaystyle{ \text{Method} }[/math] indicates whether the jig is in a batch or continuous configuration, (0 = Batch, 1 = Continuous)

- [math]\displaystyle{ A }[/math] is the particle size coefficient (-)

- [math]\displaystyle{ b }[/math] is the particle size exponent (-)

- [math]\displaystyle{ \kappa }[/math] is the velocity profile shape parameter (-)

- [math]\displaystyle{ p }[/math] is the number of bed height increments (-)

- [math]\displaystyle{ h_{\rm s} }[/math] is the relative bed cut height (m/m)

- [math]\displaystyle{ Q_{\rm M,F} }[/math] is feed solids mass flow rate by size and ore type (t/h)

- [math]\displaystyle{ (Q_{\rm M,F})_{\rm L} }[/math] is the mass flow feed rate of liquids into the jig (t/h)

- [math]\displaystyle{ \mathit{returnConcProfile} }[/math] indicates whether to return the full volume concentration of solids by density class, size and bed height, (True/False)

Note that [math]\displaystyle{ \mathit{Density} }[/math] can be specified on a per particle size per ore type basis, or with a singular value for all particle sizes of a given ore type.

Results

The results are displayed in Excel as an array corresponding to the matrix notation below:

- [math]\displaystyle{ \mathit{mdUnit\_Jig\_King} = \begin{bmatrix} \begin{bmatrix} \text{Iterations}\\ \text{Iteration error}\\ R_{\rm s}\text{ (frac)}\\ R_{\rm f}\text{ (frac)}\\ \rho_{50}\text{ (t/m}^3\text{)}\\ E_{\rm p}\text{ (t/m}^3\text{)}\\ I\text{ (-)}\\ (Q_{\rm M,C})_{\rm L}\text{ (t/h)}\\ (Q_{\rm M,T})_{\rm L}\text{ (t/h)}\\ \end{bmatrix} \begin{array}{cccccc} \begin{bmatrix} \bar d_1\text{ (mm)}\\ \vdots\\ \bar d_n\text{ (mm)} \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,C})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,C})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,C})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,C})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,T})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,T})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,T})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,T})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (P_{\rm C})_{11}\text{ (frac)} & \dots & (P_{\rm C})_{1m}\text{ (frac)}\\ \vdots & \ddots & \vdots\\ (P_{\rm C})_{n1}\text{ (frac)} & \dots & (P_{\rm C})_{nm}\text{ (frac)}\\ \end{bmatrix} & \begin{bmatrix} (P_{\rm C})_1\text{ (frac)}\\ \vdots\\ (P_{\rm C})_n\text{ (frac)}\\ \end{bmatrix} & \begin{bmatrix} (P_{\rm C})_1\text{ (frac)} & \dots & (P_{\rm C})_m\text{ (frac)}\\ \end{bmatrix} \begin{bmatrix} (\rho_{50})_1\text{ (t/m}^3\text{)}\\ \vdots\\ (\rho_{50})_n\text{ (t/m}^3\text{)}\\ \end{bmatrix} & \begin{bmatrix} (E_{\rm p})_1\text{ (t/m}^3\text{)}\\ \vdots\\ (E_{\rm p})_n\text{ (t/m}^3\text{)}\\ \end{bmatrix} & \begin{bmatrix} \begin{bmatrix} C_{111}\text{ (v/v)} & \cdots & C_{1m1}\text{ (v/v)}\\ \end{bmatrix} & \cdots & \begin{bmatrix} C_{111}\text{ (v/v)} & \cdots & C_{nm1}\text{ (v/v)}\\ \end{bmatrix}\\ \vdots & \ddots & \vdots\\ \begin{bmatrix} C_{11p}\text{ (v/v)} & \cdots & C_{1mp}\text{ (v/v)}\\ \end{bmatrix} & \cdots & \begin{bmatrix} C_{11p}\text{ (v/v)} & \cdots & C_{nmp}\text{ (v/v)}\\ \end{bmatrix}\\ \end{bmatrix}^*\\ \\ \\ \\ \\ \\ \\ \end{array} \end{bmatrix} }[/math]

where:

- [math]\displaystyle{ \text{Iterations} }[/math] is the total number of internal iterations required across all stages to reach the equilibrium stratification condition

- [math]\displaystyle{ \text{Iteration error} }[/math] is the maximum convergence error of the equilibrium stratification solutions across all stages

- [math]\displaystyle{ R_{\rm s} }[/math] is the overall recovery of solids to the concentrate (heavy) stream (frac)

- [math]\displaystyle{ R_{\rm f} }[/math] is the estimated recovery of water to the concentrate stream (frac)

- [math]\displaystyle{ (Q_{\rm M,C})_{\rm L} }[/math] is the mass flow rate of liquids to the concentrate stream (t/h)

- [math]\displaystyle{ (Q_{\rm M,T})_{\rm L} }[/math] is the mass flow rate of liquids to the tailing (light) stream (t/h)

- [math]\displaystyle{ Q_{\rm M,C} }[/math] is mass flow rate of solids to the concentrate stream (t/h)

- [math]\displaystyle{ Q_{\rm M,T} }[/math] is mass flow rate of solids to the tailing stream (t/h)

- [math]\displaystyle{ P_{\rm C} }[/math] is partition fraction of feed solids to the concentrate stream (frac)

- [math]\displaystyle{ C_{ijk} }[/math] is the volume concentration of solids of density class [math]\displaystyle{ i }[/math] and size interval [math]\displaystyle{ j }[/math] at height increment [math]\displaystyle{ k }[/math] in the equilibrium-stratified bed (v/v)

- [math]\displaystyle{ ^* }[/math] indicates optional results returned if [math]\displaystyle{ \mathit{returnConcProfile} = \text{True} }[/math]

Example

The images below show the selection of input arrays and output results in the Excel interface.

SysCAD

The sections and variable names used in the SysCAD interface are described in detail in the following tables.

Note that a Con and Partition page is provided for each connected concentrate discharge stream.

MD_GravityConcentrator page

The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here.

If this field is blank, then SysCAD will display the unit class ID. |

| Requirements | ||

| On | CheckBox | This enables the unit. If this box is not checked, then the MassFracToCon option appears below. |

| MassFracToCon | Input | Only appears if the On field above is not checked. Specifies the fraction of feed mass that reports to the concentrate stream when the model is off. |

| NumParallelUnits | Input | The number of parallel, identical units to simulate:

|

| Options | ||

| ShowQFeed | CheckBox | QFeed and associated tab pages (eg Sp) will become visible, showing the properties of the combined feed stream. |

| SizeForPassingFracCalc | Input | Size fraction for % Passing calculation. The size fraction input here will be shown in the Stream Summary section. |

| FracForPassingSizeCalc | Input | Fraction passing for Size calculation. The fraction input here will be shown in the Stream Summary section. |

| Stream Summary | ||

| MassFlow / Qm | Display | The total mass flow in each stream. |

| SolidMassFlow / SQm | Display | The Solids mass flow in each stream. |

| LiquidMassFlow / LQm | Display | The Liquid mass flow in each stream. |

| VolFlow / Qv | Display | The total Volume flow in each stream. |

| Temperature / T | Display | The Temperature of each stream. |

| Density / Rho | Display | The Density of each stream. |

| SolidFrac / Sf | Display | The Solid Fraction in each stream. |

| LiquidFrac / Lf | Display | The Liquid Fraction in each stream. |

| Passing | Display | The mass fraction passing the user-specified size (in the field SizeForPassingFracCalc) in each stream. |

| Passes | Display | The user-specified (in the field FracForPassesSizeCalc) fraction of material in each stream will pass this size fraction. |

Con page

The Con page is used to specify the required model method and associated input parameters.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Stage | ||

| On | Checkbox | This enables the stage. If off, the feed to this stage passes directly to the next stage (or tail) without partition. |

| Method | Partition (User) | The partition to concentrate for each size interval is defined by the user. |

| Partition (Rho50-Ep) | The partition to concentrate for each species and size interval is defined by the Rho50-Ep model. | |

| Partition (Pivot) | The partition to concentrate for each species and size interval is defined by the Pivot model. | |

| Partition (Stochastic) | The partition to concentrate for species and each size interval is defined by the Stochastic model. | |

| Partition (Bazin) | The partition to concentrate for species and each size interval is defined by the Bazin model. | |

| Jig (King) | The partition to concentrate for species and each size interval is defined by the King jig stratification model. | |

| Spiral (Tucker) | The partition to concentrate for each species and size interval is defined by the Tucker spiral concentrator model. | |

| Shaking Table (Tucker) | The partition to concentrate for each species and size interval is defined by the Tucker shaking table model. | |

| HelpLink | Opens a link to this page using the system default web browser. Note: Internet access is required. | |

| Parameters | ||

| Method | Batch | The jig is operated as a batch or plug flow device. |

| Continuous | The jig is operated as a continuous device. | |

| ParticleSizeCoeff / A | Input | Coefficient of the particle size power law equation. |

| ParticleSizeExp / b | Input | Exponent of the particle size power law equation. |

| Kappa | Input | Velocity profile shape parameter. |

| NumHeightInc / hInc | Input | The number of height increments subdividing the bed. |

| CutHeight / hs | Input | The relative bed cut height. |

| Liquids | ||

| LiquidsSeparMethod | Split To Con (User) | Liquids are split to concentrate by a user-defined fraction of liquids in the feed. |

| Split To Con (Model) | Liquids are split to concentrate by a fraction determined by the selected model. | |

| Con Solids Fraction | Sufficient liquids mass is recovered to the concentrate stream to yield the user-defined concentrate solids mass fraction value (if possible). | |

| Con Liquids Fraction | Sufficient liquids mass is recovered to the concentrate stream to yield the user-defined concentrate liquids mass fraction value (if possible). | |

| ConSolidsFracReqd / Con.SfReqd | Input | Required value of the mass fraction of solids in the concentrate stream. Only visible if Con Solids Fraction is selected. |

| ConLiquidsFracReqd / Con.LfReqd | Input | Required value of the mass fraction of liquids in the concentrate stream. Only visible if Con Liquids Fraction is selected. |

| LiqSplitToCon / Con.LiqSplit | Input/Display | The fraction of feed liquids recovered to the concentrate stream. |

| Results | ||

| Iterations | Display | Shows the number of internal model iterations (per SysCAD step) required to converge the stratification model. |

| MaxError | Display | Shows the quantity of the convergence error between internal model iterations. |

| CutDensity / Rho50 | Display | Unsized cut density (Rho50). |

| EcartProbable / Ep | Display | Unsized Ecart Probable (Ep). |

| Imperfection / I | Display | Unsized partition Imperfection (I). |

Partition page

The Partition page is used to display (or specify) the partition by species/component/element/individual phase and size values.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Partition | ||

| Method | Model / User | Select model-calculated or user-defined partition to separate each solids species type. |

| Density | Display | Density of each solid species. |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| CutDensity / Rho50 | Display | Cut density (Rho50) of all particles in each size interval. |

| EcartProbable / Ep | Display | Ecart Probable (Ep) of all particles in each size interval. |

| All (All column) | Display |

|

| Partition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per species) | Display |

|

| CmpPartition | ||

| Components | Hides or shows component partition table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| CmpPartition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per component) | Display |

|

| ElePartition | ||

| Elements | Hides or shows element partition table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| ElePartition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per element) | Display |

|

| IPhPartition | ||

| IPhases | Hides or shows individual phases partition table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| IPhPartition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per individual phase) | Display |

|

About page

This page is provides product and licensing information about the Met Dynamics Models SysCAD Add-On.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| About | ||

| HelpLink | Opens a link to the Installation and Licensing page using the system default web browser. Note: Internet access is required. | |

| Information | Copies Product and License information to the Windows clipboard. | |

| Product | ||

| Name | Display | Met Dynamics software product name |

| Version | Display | Met Dynamics software product version number. |

| BuildDate | Display | Build date and time of the Met Dynamics Models SysCAD Add-On. |

| License | ||

| File | This is used to locate a Met Dynamics software license file. | |

| Location | Display | Type of Met Dynamics software license or file name and path of license file. |

| SiteCode | Display | Unique machine identifier for license authorisation. |

| ReqdAuth | Display | Authorisation level required, MD-SysCAD Full or MD-SysCAD Runtime. |

| Status | Display | License status, LICENSE_OK indicates a valid license, other messages report licensing errors. |

| IssuedTo | Display | Only visible if Met Dynamics license file is used. Name of organisation/seat the license is authorised to. |

| ExpiryDate | Display | Only visible if Met Dynamics license file is used. License expiry date. |

| DaysLeft | Display | Only visible if Met Dynamics license file is used. Days left before the license expires. |

Additional notes

- Solid species that do not possess a particle size distribution property are split according to the overall mass split of the default particle size distribution species selected in the SysCAD Project Configuration.

- If the default particle size distribution species is not present in the unit feed, the overall split of all other species with particle size distributions combined is used, as determined by the model.

- Gas phase species report directly to the tail stream without split.