Tumbling Mill (Media Strings): Difference between revisions

md>Scott.Munro mNo edit summary |

imported>Scott.Munro m (→Description) |

||

| (4 intermediate revisions by 3 users not shown) | |||

| Line 8: | Line 8: | ||

Sepúlveda mathematically derives an approach to estimating the mass weight by size distribution of both individual and overall combined strings at recharge equilibrium. | Sepúlveda mathematically derives an approach to estimating the mass weight by size distribution of both individual and overall combined strings at recharge equilibrium. | ||

This information may be useful for understanding the effect of changing recharge media sizes or proportions on the overall distribution of media in a mill. It may also be useful for simulation purposes, where either full media size distributions or characteristic sizes are input parameters (e.g. [[AG/SAG Mill ( | This information may be useful for understanding the effect of changing recharge media sizes or proportions on the overall distribution of media in a mill. It may also be useful for simulation purposes, where either full media size distributions or characteristic sizes are input parameters (e.g. [[AG/SAG Mill (Variable Rates)|AG/SAG]], [[Ball Mill (Perfect Mixing)|Perfect Mixing ball mill]]). | ||

== Model theory == | == Model theory == | ||

{{Restricted content}} | |||

<hide> | |||

</hide><div class="user-show"> | |||

=== Grinding media wear kinetics === | === Grinding media wear kinetics === | ||

</div><hide> | |||

Sepúlveda applies a linear kinetic model to characterise the progression of media element wear. The rate of mass loss is proportional to the surface area exposed to wearing by the relation: | Sepúlveda applies a linear kinetic model to characterise the progression of media element wear. The rate of mass loss is proportional to the surface area exposed to wearing by the relation: | ||

| Line 39: | Line 44: | ||

where <math>d^{\rm R}</math> is the initial size of the balls (mm), i.e. the recharge size. | where <math>d^{\rm R}</math> is the initial size of the balls (mm), i.e. the recharge size. | ||

</hide><div class="user-show"> | |||

=== Media string size distribution === | === Media string size distribution === | ||

</div><hide> | |||

Sepúlveda derived a population balance relationship for the cumulative mass fraction of media elements smaller than size <math>d</math>, <math>F_3(d)</math> (w/w): | Sepúlveda derived a population balance relationship for the cumulative mass fraction of media elements smaller than size <math>d</math>, <math>F_3(d)</math> (w/w): | ||

| Line 55: | Line 62: | ||

These expressions describe the mass distribution of media by size for each individual string at recharge equilibrium. | These expressions describe the mass distribution of media by size for each individual string at recharge equilibrium. | ||

</hide><div class="user-show"> | |||

=== Specific surface area === | === Specific surface area === | ||

</div><hide> | |||

The specific surface area, <math>a</math> (m<sup>2</sup>/m<sup>3</sup>), of a string is: | The specific surface area, <math>a</math> (m<sup>2</sup>/m<sup>3</sup>), of a string is: | ||

| Line 79: | Line 88: | ||

:<math>v_j = \dfrac {\prod\limits_{k=1}^{m} r_j a_k}{\sum\limits_{j=1}^{m} \left ( \prod\limits_{k=1}^{m} r_j a_k \right )}, \;\;\;\; j \neq k</math> | :<math>v_j = \dfrac {\prod\limits_{k=1}^{m} r_j a_k}{\sum\limits_{j=1}^{m} \left ( \prod\limits_{k=1}^{m} r_j a_k \right )}, \;\;\;\; j \neq k</math> | ||

</hide><div class="user-show"> | |||

=== Media charge size distribution === | === Media charge size distribution === | ||

</div><hide> | |||

The overall cumulative mass fraction passing distribution of all strings in the mill is: | The overall cumulative mass fraction passing distribution of all strings in the mill is: | ||

| Line 89: | Line 100: | ||

:<math>f_3(d_i)_{\rm All} = \sum\limits_{j=1}^{m} v_j f_3(d_i)_j</math> | :<math>f_3(d_i)_{\rm All} = \sum\limits_{j=1}^{m} v_j f_3(d_i)_j</math> | ||

</hide><div class="user-show"> | |||

=== Estimating scrap size === | === Estimating scrap size === | ||

</div><hide> | |||

The scrap size (<math>d^{\rm S}</math>) from a '''grate discharge''' mill is likely to be related to size of the largest aperture in the grate, i.e. the size at which scrap balls can first be ejected. | The scrap size (<math>d^{\rm S}</math>) from a '''grate discharge''' mill is likely to be related to size of the largest aperture in the grate, i.e. the size at which scrap balls can first be ejected. | ||

| Line 98: | Line 111: | ||

which may provide a useful estimate for media string calculations. | which may provide a useful estimate for media string calculations. | ||

</hide> | |||

== Excel == | == Excel == | ||

Latest revision as of 07:26, 1 May 2025

Description

The article outlines a methodology for estimating the size distribution of media elements in grinding mills at recharge equilibrium, as proposed by Sepúlveda (2004):[1]

- The constant recharging, wearing and ejection of media elements in a mill results in a string of worn media elements of distributed sizes which descended from an original unworn (make-up) element.

- Charging a mill with a mixture of new media make-up sizes results in multiple strings coexisting, and combining into an effective overall string.

- When the addition rate of new media elements matches the ejection rate of scrap elements, the media strings are said to be in recharge equilibrium.

Sepúlveda mathematically derives an approach to estimating the mass weight by size distribution of both individual and overall combined strings at recharge equilibrium.

This information may be useful for understanding the effect of changing recharge media sizes or proportions on the overall distribution of media in a mill. It may also be useful for simulation purposes, where either full media size distributions or characteristic sizes are input parameters (e.g. AG/SAG, Perfect Mixing ball mill).

Model theory

Grinding media wear kinetics

Media string size distribution

Specific surface area

Media charge size distribution

Estimating scrap size

Excel

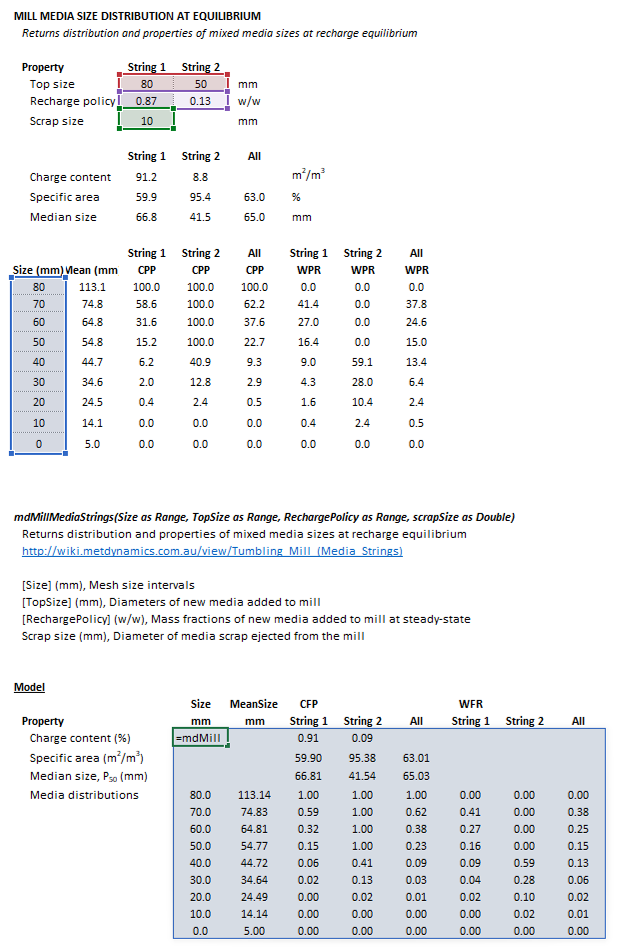

The grinding mill media strings model may be invoked from the Excel formula bar with the following function call:

=mdMillMediaStrings(Size as Range, TopSize as Range, RechargePolicy as Range, scrapSize as Double)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The input arrays and model results are defined below in matrix notation, along with example images showing the selection of the same arrays in the Excel interface:

[math]\displaystyle{ \begin{array}{l} Size = \begin{bmatrix} d_{1}\text{ (mm)}\\ \vdots\\ d_n\text{ (mm)}\\ \end{bmatrix}, & & & \begin{array}{lll} TopSize= \begin{bmatrix} {(d^{\rm R}})_{1}\text{ (mm)} & \dots & {(d^{\rm R}})_m\text{ (mm)}\\ \end{bmatrix}, & & & RechargePolicy = \begin{bmatrix} r_1\text{ (w/w)} & \dots & r_{\rm m}\text{ (w/w)}\\ \end{bmatrix} & & & scrapSize = \left [ d^{\rm S} \right ] \end{array} \end{array} }[/math]

[math]\displaystyle{ mdMillMediaStrings = \begin{bmatrix} \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} v_1\text{ (v/v)} & \dots & v_m\text{ (v/v)}\\ \end{bmatrix} & \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} - \end{bmatrix} \\ \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} a_1\text{ (m}^2\text{/m}^3\text{)} & \dots & a_m\text{ (m}^2\text{/m}^3\text{)}\\ \end{bmatrix} & \begin{bmatrix} a_{\rm All}\text{ (m}^2\text{/m}^3\text{)} \end{bmatrix} & \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} - \end{bmatrix}\\ \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} (P_{50})_1\text{ (mm)} & \dots & (P_{50})_m\text{ (mm)}\\ \end{bmatrix} & \begin{bmatrix} (P_{50})_{\rm All}\text{ (mm)} \end{bmatrix} & \begin{bmatrix} - \end{bmatrix} & \begin{bmatrix} - \end{bmatrix}\\ \begin{bmatrix} \bar d_{1}\text{ (mm)}\\ \vdots\\ \bar d_n\text{ (mm)}\\ \end{bmatrix} & \begin{bmatrix} F_3(d_1)_1\text{ (CFP)} & \dots & F_3(d_1)_m\text{ (CFP)}\\ \vdots & \ddots & \vdots\\ F_3(d_n)_1\text{ (CFP)} & \dots & F_3(d_n)_m\text{ (CFP)}\\ \end{bmatrix} & \begin{bmatrix} F_3(d_1)_{\rm All}\text{ (CFP)}\\ \vdots\\ F_3(d_n)_{\rm All}\text{ (CFP)}\\ \end{bmatrix} & \begin{bmatrix} f_3(d_1)_1\text{ (WFR)} & \dots & f_3(d_1)_m\text{ (WFR)}\\ \vdots & \ddots & \vdots\\ f_3(d_n)_1\text{ (WFR)} & \dots & f_3(d_n)_m\text{ (WFR)}\\ \end{bmatrix} & \begin{bmatrix} f_3(d_1)_{\rm All}\text{ (WFR)}\\ \vdots\\ f_3(d_n)_{\rm All}\text{ (WFR)}\\ \end{bmatrix} \end{bmatrix}\;\;\;\;\;\; }[/math]

where [math]\displaystyle{ P_{50} }[/math] is the median size, the 50% passing size (mm).

SysCAD

Media strings are an optional calculation for grinding mill units. If selected, the input and display parameters below are shown.

References

- ↑ Sepúlveda, J.E., 2004. Methodologies for the evaluation of grinding media consumption rates at full plant scale. Minerals engineering, 17(11-12), pp.1269-1279.