Dewatering Screen (Ng): Difference between revisions

imported>Scott.Munro m (Scott.Munro moved page Draft:Dewatering Screen (Ng) to Dewatering Screen (Ng) without leaving a redirect) |

imported>Scott.Munro mNo edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 8: | Line 8: | ||

<hide> | <hide> | ||

</hide><div class="user-show"> | |||

=== Dewatering === | === Dewatering === | ||

</div><hide> | |||

Ng (1990) developed a model for estimating the final moisture content of material discharged from a dewatering screen.{{Ng (1990)}}{{King (2012)}} | Ng (1990) developed a model for estimating the final moisture content of material discharged from a dewatering screen.{{Ng (1990)}}{{King (2012)}} | ||

| Line 14: | Line 16: | ||

This model integrates sub-models for ''bed transport'' and ''dewatering rate'' to predict dewatering performance under varying operating conditions. | This model integrates sub-models for ''bed transport'' and ''dewatering rate'' to predict dewatering performance under varying operating conditions. | ||

</hide><div class="user-show"> | |||

==== Bed transport ==== | ==== Bed transport ==== | ||

</div><hide> | |||

The bed transport sub-model accounts for the dynamics of screen motion and the influence of gravity using the acceleration ratio, <math>G_{\rm y}</math>: | The bed transport sub-model accounts for the dynamics of screen motion and the influence of gravity using the acceleration ratio, <math>G_{\rm y}</math>: | ||

| Line 56: | Line 60: | ||

where <math>L</math> is screen length (m). | where <math>L</math> is screen length (m). | ||

</hide><div class="user-show"> | |||

==== Dewatering rate ==== | ==== Dewatering rate ==== | ||

</div><hide> | |||

The rate of moisture removal, and hence the final moisture content, <math>S</math> (w/w), is governed by the following rate equation: | The rate of moisture removal, and hence the final moisture content, <math>S</math> (w/w), is governed by the following rate equation: | ||

| Line 80: | Line 86: | ||

where <math>p = 0.234</math>, <math>q_1 = 0.33</math>, and <math>q_2 = 0.081</math> for the coal slurries investigated by Ng.{{King (2012)}} | where <math>p = 0.234</math>, <math>q_1 = 0.33</math>, and <math>q_2 = 0.081</math> for the coal slurries investigated by Ng.{{King (2012)}} | ||

</hide><div class="user-show"> | |||

==== Dewatering capacity ==== | ==== Dewatering capacity ==== | ||

</div><hide> | |||

The specific dewatering capacity, <math>W</math> (t/h·m), is given by:{{King (2012)}} | The specific dewatering capacity, <math>W</math> (t/h·m), is given by:{{King (2012)}} | ||

| Line 109: | Line 117: | ||

where <math>Q_{\rm M,F}</math> is the feed rate of solids to the screen (t/h). | where <math>Q_{\rm M,F}</math> is the feed rate of solids to the screen (t/h). | ||

</hide><div class="user-show"> | |||

=== Classification === | === Classification === | ||

</div><hide> | |||

The dewatering screen model combines particle classification with dewatering performance. | The dewatering screen model combines particle classification with dewatering performance. | ||

</hide><div class="user-show"> | |||

==== Simple partition ==== | ==== Simple partition ==== | ||

</div><hide> | |||

A simple particle classification method s provided, based on King's (2012) suggestion that particles smaller than the aperture size pass to the undersize stream in proportion to water.{{King (2012)}} Accordingly, the classification of particles to the oversize stream is expressed as: | A simple particle classification method s provided, based on King's (2012) suggestion that particles smaller than the aperture size pass to the undersize stream in proportion to water.{{King (2012)}} Accordingly, the classification of particles to the oversize stream is expressed as: | ||

| Line 132: | Line 144: | ||

The water recovery to the undersize stream (<math>R_{\rm w}</math>) depends on the final moisture content of the oversize stream (<math>S</math>), as determined by the dewatering sub-model. Since moisture content also depends on the solids flow rate to the oversize stream, <math>E_{{\rm oa}i}</math> and <math>R_{\rm w}</math> are inherently linked. This dependency is resolved iteratively to align the final moisture content computed from <math>E_{{\rm oa}i}</math> and <math>R_{\rm w}</math> with the target value (<math>S</math>). | The water recovery to the undersize stream (<math>R_{\rm w}</math>) depends on the final moisture content of the oversize stream (<math>S</math>), as determined by the dewatering sub-model. Since moisture content also depends on the solids flow rate to the oversize stream, <math>E_{{\rm oa}i}</math> and <math>R_{\rm w}</math> are inherently linked. This dependency is resolved iteratively to align the final moisture content computed from <math>E_{{\rm oa}i}</math> and <math>R_{\rm w}</math> with the target value (<math>S</math>). | ||

</hide><div class="user-show"> | |||

==== Partition by size ==== | ==== Partition by size ==== | ||

</div><hide> | |||

:''Main article'': [[Vibrating Screen (Whiten)]] | :''Main article'': [[Vibrating Screen (Whiten)]] | ||

| Line 150: | Line 164: | ||

::Unlike the first mode, this approach eliminates the need for numerical iteration. | ::Unlike the first mode, this approach eliminates the need for numerical iteration. | ||

</hide><div class="user-show"> | |||

=== Additional notes === | === Additional notes === | ||

</div><hide> | |||

The dewatering model incorporates parameters originally derived by Ng (1990) from an analysis of coal slurries processed on a 300 mm x 3,156 mm screen.{{Ng (1990)}} | The dewatering model incorporates parameters originally derived by Ng (1990) from an analysis of coal slurries processed on a 300 mm x 3,156 mm screen.{{Ng (1990)}} | ||

| Line 334: | Line 350: | ||

where: | where: | ||

* <math>(E_{\rm US})_{\rm A}</math> is the actual efficiency of undersize removal achieved by the screen (frac) | * <math>(E_{\rm US})_{\rm A}</math> is the actual efficiency of undersize removal achieved by the screen (frac) | ||

* <math>n_{\rm L}</math> is number of trials parameter (/m) specified by the user if <math>\text{Classification Method}=2</math>, or required to achieve the target efficiency | * <math>n_{\rm L}</math> is number of trials parameter (/m) specified by the user if <math>\text{Classification Method}=2</math>, or required to achieve the target efficiency if <math>\text{Classification Method}=1\text{ or }3</math> | ||

* <math>Q_{\rm M,OS}</math> is mass flow rate of solids to the oversize stream (t/h) | * <math>Q_{\rm M,OS}</math> is mass flow rate of solids to the oversize stream (t/h) | ||

* <math>Q_{\rm M,US}</math> is mass flow rate of solids to the undersize stream (t/h) | * <math>Q_{\rm M,US}</math> is mass flow rate of solids to the undersize stream (t/h) | ||

| Line 355: | Line 371: | ||

The sections and variable names used in the SysCAD interface are described in detail in the following tables. | The sections and variable names used in the SysCAD interface are described in detail in the following tables. | ||

Note that both a '''Deck''' page and a '''Partition''' page are | Note that both a '''Deck''' page and a '''Partition''' page are provided for each connected oversize discharge stream. | ||

{{SysCAD (Page, Screen, DLL*Screen)}} | {{SysCAD (Page, Screen, DLL*Screen)}} | ||

| Line 377: | Line 393: | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

|Whiten (Efficiency =R w) | |Whiten (Efficiency =R w) | ||

|The Whiten vibrating screen model is used to determine the classification partition. The screening efficiency is set to equal | |The Whiten vibrating screen model is used to determine the classification partition. The screening efficiency is set to equal the fraction of water recovered to US (Rw). | ||

|- style="vertical-align:top;" | |- style="vertical-align:top;" | ||

|Whiten (Specify nL) | |Whiten (Specify nL) | ||

| Line 581: | Line 597: | ||

* [[Vibrating Screen (Whiten)]] | * [[Vibrating Screen (Whiten)]] | ||

* [[Partition (Size, Whiten and White)]] | * [[Partition (Size, Whiten and White)]] | ||

== External links == | |||

* [https://help.syscad.net/Met_Dynamics_-_Screen Met Dynamics - Screen (help.syscad.net)] | |||

* [https://help.syscad.net/Example_-_09_Met_Dynamics_Projects#Gravity,_Dense_Medium_and_Magnetic_Separation_Example Gravity, Dense Medium, and Magnetic Separation Example project (help.syscad.net)] | |||

== References == | == References == | ||

Latest revision as of 13:33, 1 May 2025

Description

This article describes the Ng (1990) model for a dewatering screen, with additions for particle classification.[1][2]

Model theory

Dewatering

Bed transport

Dewatering rate

Dewatering capacity

Classification

Simple partition

Partition by size

Additional notes

Excel

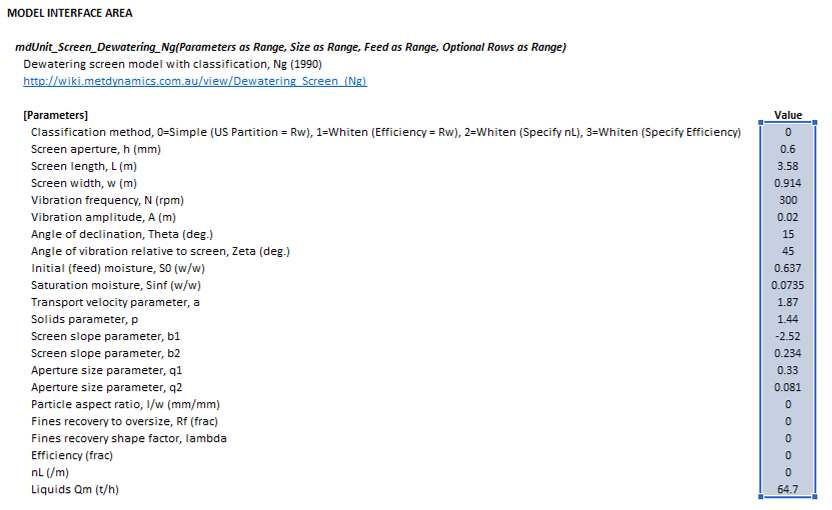

The Ng dewatering screen model may be invoked from the Excel formula bar with the following function call:

=mdUnit_Screen_Dewatering_Ng(Parameters as Range, Size as Range, Feed as Range, Optional Rows as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

Inputs

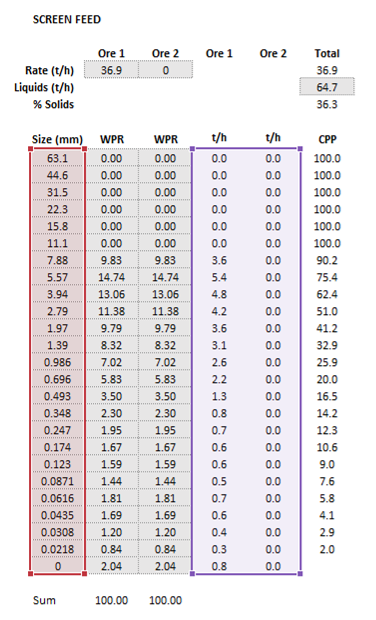

The required inputs are defined below in matrix notation with elements corresponding to cells in Excel row ([math]\displaystyle{ i }[/math]) x column ([math]\displaystyle{ j }[/math]) format:

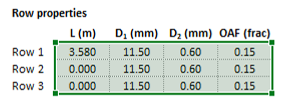

- [math]\displaystyle{ \mathit{Parameters} = \begin{bmatrix} \text{Classification Method}\\ h \text{ (mm)}\\ L \text{ (m)}\\ w \text{ (m)}\\ N \text{ (rpm)}\\ A \text{ (m)}\\ \theta \text{ (deg.)}\\ \zeta\text{ (deg.)}\\ S_{\infty} \text{ (w/w)}\\ p \text{ (-)}\\ q_1 \text{ (-)}\\ q_2 \text{ (-)}\\ a \text{ (-)}\\ b_1 \text{ (-)}\\ b_2 \text{ (-)}\\ d_{\rm AR} \text{ (mm/mm)}\\ R_{\rm f} \text{ (frac)}\\ \lambda\\ (E_{\rm US})_{\rm T} \text{ (frac)}\\ n_{\rm L} \text{ (/m)}\\ (Q_{\rm M,F})_{\rm L}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{Size} = \begin{bmatrix} d_{1}\text{ (mm)}\\ \vdots\\ d_n\text{ (mm)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{Feed}= \begin{bmatrix} (Q_{\rm M,F})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,F})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,F})_{nm}\text{ (t/h)}\\ \end{bmatrix},\;\;\;\;\;\; \mathit{Rows} = \begin{bmatrix} L_1\text{ (m)} & (D_1)_1\text{ (mm)} & (D_2)_1\text{ (mm)} & (f_{\rm o})_1\text{ (m}^2\text{/m}^2\text{)}\\ \vdots & \vdots & \vdots & \vdots\\ L_p\text{ (m)} & (D_1)_p\text{ (mm)} & (D_2)_p\text{ (mm)} & (f_{\rm o})_p\text{ (m}^2\text{/m}^2\text{)}\\ \end{bmatrix}^*\;\;\;\;\;\; }[/math]

where:

- [math]\displaystyle{ \text{Classification Method} }[/math] indicates whether the model applies a user-specified [math]\displaystyle{ n_L }[/math] parameter or solves the [math]\displaystyle{ n_L }[/math] value required to achieve a user-specified target efficiency (0 = Simple (US Partition = Rw), 1 = Whiten (Efficiency = Rw), 2 = Whiten (Specify nL), 3 = Whiten (Specify Efficiency))

- [math]\displaystyle{ n_{\rm L} }[/math] is number of trials parameter (/m) applied if [math]\displaystyle{ \text{Method}=2 }[/math], ignored otherwise

- [math]\displaystyle{ (E_{\rm US})_{\rm T} }[/math] is the target screen efficiency (frac) if [math]\displaystyle{ \text{Method}=3 }[/math], ignored otherwise

- [math]\displaystyle{ d_i }[/math] is the size of the square mesh interval that feed mass is retained on (mm)

- [math]\displaystyle{ m }[/math] is the number of ore types

- [math]\displaystyle{ Q_{\rm M,F} }[/math] is feed solids mass flow rate by size and ore type (t/h)

- [math]\displaystyle{ (Q_{\rm M,F})_{\rm L} }[/math] is the mass flow feed rate of liquids to the screen (t/h)

- [math]\displaystyle{ ^* }[/math] indicates the [math]\displaystyle{ \mathit{Rows} }[/math] array is only required when the [math]\displaystyle{ \text{Classification Method} }[/math] is 1, 2 or 3 (Whiten classification).

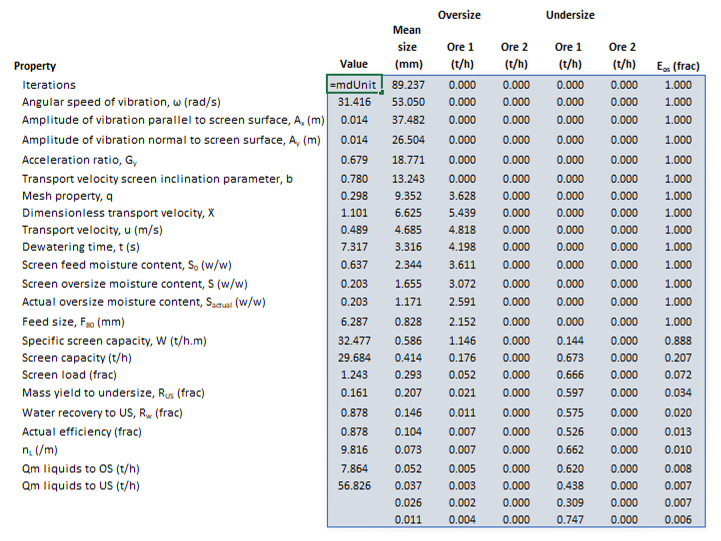

Results

The results are displayed in Excel as an array corresponding to the matrix notation below:

- [math]\displaystyle{ mdUnit\_Screen\_Dewatering\_Ng = \begin{bmatrix} \begin{array}{c} \begin{bmatrix} \text{Iterations}\\ \omega \text{ (rad/s)}\\ A_{x} \text{ (m)}\\ A_{y} \text{ (m)}\\ G_{y} \text{ (-)}\\ b \text{ (-)}\\ q \text{ (-)}\\ \dot X \text{ (-)}\\ u \text{ (m/s)}\\ t \text{ (s)}\\ S_0 \text{ (w/w)}\\ S \text{ (w/w)}\\ S_{\rm actual} \text{ (w/w)}\\ F_{80} \text{ (mm)}\\ W \text{ (t/h.m)}\\ Q_{\rm W}\text{ (t/h)}\\ \text{Load (frac)}\\ R_{\rm US} \text{ (frac)}\\ R_{\rm w} \text{ (frac)}\\ (E_{\rm US})_{\rm A}\\ n_{\rm L} \text{ (/m)}\\ \end{bmatrix} &\\ &\\ \end{array} & \begin{array}{c} \begin{bmatrix} \bar d_1\text{ (mm)}\\ \vdots\\ \bar d_n\text{ (mm)} \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,OS})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,OS})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,OS})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,OS})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (Q_{\rm M,US})_{11}\text{ (t/h)} & \dots & (Q_{\rm M,US})_{1m}\text{ (t/h)}\\ \vdots & \ddots & \vdots\\ (Q_{\rm M,US})_{n1}\text{ (t/h)} & \dots & (Q_{\rm M,US})_{nm}\text{ (t/h)}\\ \end{bmatrix} & \begin{bmatrix} (E_{\rm oa})_1\text{ (frac)}\\ \vdots\\ (E_{\rm oa})_n\text{ (frac)} \end{bmatrix} \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \\ \end{array} \end{bmatrix} }[/math]

where:

- [math]\displaystyle{ (E_{\rm US})_{\rm A} }[/math] is the actual efficiency of undersize removal achieved by the screen (frac)

- [math]\displaystyle{ n_{\rm L} }[/math] is number of trials parameter (/m) specified by the user if [math]\displaystyle{ \text{Classification Method}=2 }[/math], or required to achieve the target efficiency if [math]\displaystyle{ \text{Classification Method}=1\text{ or }3 }[/math]

- [math]\displaystyle{ Q_{\rm M,OS} }[/math] is mass flow rate of solids to the oversize stream (t/h)

- [math]\displaystyle{ Q_{\rm M,US} }[/math] is mass flow rate of solids to the undersize stream (t/h)

Example

The images below show the selection of input arrays and output results in the Excel interface.

SysCAD

The sections and variable names used in the SysCAD interface are described in detail in the following tables.

Note that both a Deck page and a Partition page are provided for each connected oversize discharge stream.

MD_Screen page

The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here.

If this field is blank, then SysCAD will display the unit class ID. |

| Requirements | ||

| On | CheckBox | This enables the unit. If this box is not checked, then the MassFracToOS option appears below. |

| MassFracToOS | Input | Only appears if the On field above is not checked. Specifies the fraction of feed mass that reports to the overflow stream when the model is off. |

| NumParallelUnits | Input | The number of parallel, identical units to simulate:

|

| Options | ||

| ShowQFeed | CheckBox | QFeed and associated tab pages (eg Sp) will become visible, showing the properties of the combined feed stream. |

| SizeForPassingFracCalc | Input | Size fraction for % Passing calculation. The size fraction input here will be shown in the Stream Summary section. |

| FracForPassingSizeCalc | Input | Fraction passing for Size calculation. The fraction input here will be shown in the Stream Summary section. |

| Stream Summary | ||

| MassFlow / Qm | Display | The total mass flow in each stream. |

| SolidMassFlow / SQm | Display | The Solids mass flow in each stream. |

| LiquidMassFlow / LQm | Display | The Liquid mass flow in each stream. |

| VolFlow / Qv | Display | The total Volume flow in each stream. |

| Temperature / T | Display | The Temperature of each stream. |

| Density / Rho | Display | The Density of each stream. |

| SolidFrac / Sf | Display | The Solid Fraction in each stream. |

| LiquidFrac / Lf | Display | The Liquid Fraction in each stream. |

| Passing | Display | The mass fraction passing the user-specified size (in the field SizeForPassingFracCalc) in each stream. |

| Passes | Display | The user-specified (in the field FracForPassesSizeCalc) fraction of material in each stream will pass this size fraction. |

Deck page

The Deck page is used to specify the required model method and associated input parameters.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Deck | ||

| On | Checkbox | This enables the deck. If off, the feed to this deck passes directly to the next deck (or undersize) without partition. |

| Method | Partition (User) | The partition to oversize for each size interval is defined by the user. Different values can be used for different solids. |

| Partition (Reid-Plitt) | The partition to oversize for each size interval is defined by a Reid-Plitt efficiency curve. Different parameters can be used for different solids. | |

| Partition (Whiten-Beta) | The partition to oversize for each size interval is defined by a Whiten-Beta efficiency curve. Different parameters can be used for different solids. | |

| Vibrating (Karra) | The Karra vibrating screen model is used to determine the partition of solids to oversize and undersize for each size interval. | |

| Vibrating (Whiten) | The Whiten vibrating screen model is used to determine the partition of solids to oversize and undersize for each size interval. | |

| Vibrating (Metso) | The Metso vibrating screen model is used to determine the partition of solids to oversize and undersize for each size interval. | |

| Fine Wet (Mwale) | The Mwale fine wet screen model is used to determine the partition of solids to oversize and undersize for each size interval. | |

| Dewatering (Ng) | The Ng dewatering screen model is used to determine the moisture content of oversize material, and the partition of solids to oversize and undersize for each size interval. | |

| HelpLink | Opens a link to this page using the system default web browser. Note: Internet access is required. | |

| Parameters | ||

| Classification | Simple (US Partition = Rw) | The partition to US for each size interval smaller than the aperture size is set to equal the fraction of water recovered to US (Rw). |

| Whiten (Efficiency =R w) | The Whiten vibrating screen model is used to determine the classification partition. The screening efficiency is set to equal the fraction of water recovered to US (Rw). | |

| Whiten (Specify nL) | The Whiten vibrating screen model is used to determine the classification partition. The user specifies the value of the nL parameter and efficiency is computed. | |

| Whiten (Specify Efficiency) | The Whiten vibrating screen model is used to determine the classification partition. The value of the nL parameter is adjusted to achieve a user-specified target efficiency value. | |

| ScreenAperture / h | Input / Display | Representative screen aperture. Set to smallest row aperture dimension if Whiten classification method selected above. |

| ScreenLength / L | Input / Display | Length of screening surface. Set to sum of row lengths if Whiten classification method selected above. |

| ScreenWidth / w | Input | Width of the screening surface. |

| VibFrequency / N | Input | Vibrational frequency of the screen motion. |

| VibAmplitude | Input | Amplitude of vibration of the screen motion. |

| DeclinationAngle / Theta | Input | Angle of declination of the screen. |

| VibrationAngle / Zeta | Input | Angle of vibrational motion of the screen, relative to the screening surface. |

| SaturationMoisture / Sinf | Input | Minimum possible moisture content of material at infinite dewatering time. |

| SolidsParameter / p | Input | Kinetic equation parameter for solid material. |

| ApertureParameter1 / q1 | Input | Constant of the kinetic exponent mesh size equation. |

| ApertureParameter2 / q2 | Input | Coefficient of the kinetic exponent mesh size equation. |

| VelocityParameter / a | Input | Coefficient of transport velocity equation. |

| SlopeParameter1 / b1 | Input | Constant of the screen slope transport velocity exponent equation. |

| SlopeParameter2 / b2 | Input | Coefficient of the screen slope transport velocity exponent equation. |

| nL | Input | User specified value of the nL parameter. Only visible if the Whiten (Specify nL) classification method is selected above. |

| Efficiency | Input | User specified target value of screen efficiency. Only visible if Whiten (Specify Efficiency) classification method is selected above. |

| ParticleAspectRatio / ParticleAR | Input | Value of the particle aspect ratio, i.e. (second longest dimension):(longest dimension). Only visible if a Whiten classification method is selected above. |

| Rf | Input | Fines recovery parameter, fraction of the finest particles or liquids split to oversize stream. Only visible if a Whiten classification method is selected above. |

| Lambda | Input | Fines recovery parameter, shape factor. Only visible if a Whiten classification method is selected above. |

| Rows | ||

| NumRows | Input | Number of screen panel rows. Only visible if a Whiten classification method is selected above. |

| L | Input | Length of the row in the direction of travel. Only visible if a Whiten classification method is selected above. |

| ApertureL / D1 | Input | Aperture length. Only visible if a Whiten classification method is selected above. |

| ApertureW / D2 | Input | Aperture width. Only visible if a Whiten classification method is selected above. |

| OpenArea / fo | Input | Open area fraction of the row. Only visible if a Whiten classification method is selected above. |

| Liquids | ||

| LiquidsSeparMethod | Split To OS (User) | Liquids are split to oversize by a user-defined fraction of liquids in the feed. |

| Dewatering (S) | Final moisture content of oversize (S) is determined by the Ng dewatering screen method. | |

| OS Solids Fraction | Sufficient liquids mass is recovered to the oversize stream to yield the user-defined oversize solids mass fraction value (if possible). | |

| OS Liquids Fraction | Sufficient liquids mass is recovered to the oversize stream to yield the user-defined oversize liquids mass fraction value (if possible). | |

| OSSolidsFracReqd / OS.SfReqd | Input | Required value of the mass fraction of solids in the oversize stream. Only visible if OS Solids Fraction is selected. |

| OSLiquidsFracReqd / OS.LfReqd | Input | Required value of the mass fraction of liquids in the oversize stream. Only visible if OS Liquids Fraction is selected. |

| LiqSplitToOS / OS.LiqSplit | Input/Display | The fraction of feed liquids recovered to the oversize stream. |

| Results | ||

| Iterations | Display | Number of iterations required to set US partition or screening efficiency equal to water recovery to US (Rw) value. Only visible if Simple (US Partition = Rw) or Whiten (Efficiency = Rw) classification method is selected above. |

| AngularVibSpeed / Omega | Display | Angular speed of vibration of the screening surface. |

| ParallelVibAmp / Ax | Display | Amplitude of vibration of screen motion in direction parallel to screening surface. |

| NormalVibAmp / Ay | Display | Amplitude of vibration of screen motion in direction normal to screening surface. |

| AccelerationRatio / Gy | Display | Ratio of gravitational to vibrational acceleration of screen surface motion. |

| VelIncParameter / b | Display | Value of the transport velocity equation exponent. |

| MeshProperty / q | Display | Value of the kinetic equation exponent. |

| DimTransportVelocity / Xdot | Display | Dimensionless transport velocity. |

| TransportVelocity / u | Display | Transport velocity of material along screen. |

| DewateringTime / t | Display | Residence time of material on screen during dewatering. |

| FeedMoisture / S0 | Display | Moisture content of screen feed material. |

| OversizeMoisture / S | Display | Predicted moisture content of dewatered screen oversize material. |

| ActualOSMoisture / Sactual | Display | Actual, realised moisture content of dewatered screen oversize material. |

| WaterRecoveryToUS / Rw | Display | Fraction of feed water recovered to screen undersize stream. |

| ActualEfficiency | Display | Actual efficiency achieved by screen model. Only visible if a Whiten classification method is selected above. |

| nL | Display | Actual value of screen classification kinetic parameter. Only visible if a Whiten classification method is selected above. |

| SpecScreenCapacity / W | Display | Specific dewatering capacity of screen (per unit width). |

| ScreenCapacity | Display | Maximum dewatering capacity of screen. |

| Feed.SQm | Display | Feed rate of solids to screen. |

| ScreenLoad | Display | Ratio of screen solids feed rate to screen capacity. |

Partition page

The Partition page is used to display (or specify) the partition by species/component/element/individual phase and size values.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| Distribution | ||

| Name | Display | Shows the name of the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| IntervalCount | Display | Shows the number of size intervals in the SysCAD Size Distribution (PSD) quality associated with the feed stream. |

| SpWithPSDCount | Display | Shows the number of species in the feed stream assigned with the SysCAD Size Distribution (PSD) quality. |

| Partition | ||

| Method | Model / User | Select model-calculated or user-defined partition to separate each solids species type. |

| Density | Display | Density of each solid species. |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series.

|

| All (All column) | Display |

|

| Partition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per species) | Display |

|

| CmpPartition | ||

| Components | Hides or shows component partition table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| CmpPartition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per component) | Display |

|

| ElePartition | ||

| Elements | Hides or shows element partition table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| ElePartition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per element) | Display |

|

| IPhPartition | ||

| IPhases | Hides or shows individual phases partition table. | |

| Size | Display | Size of each interval in mesh series. |

| MeanSize | Display | Geometric mean size of each interval in mesh series. |

| All (All column) | Display |

|

| IPhPartition | Display |

|

| All (All row, All column) | Display |

|

| All (All row, per individual phase) | Display |

|

About page

This page is provides product and licensing information about the Met Dynamics Models SysCAD Add-On.

| Tag (Long/Short) | Input / Display | Description/Calculated Variables/Options |

|---|---|---|

| About | ||

| HelpLink | Opens a link to the Installation and Licensing page using the system default web browser. Note: Internet access is required. | |

| Information | Copies Product and License information to the Windows clipboard. | |

| Product | ||

| Name | Display | Met Dynamics software product name |

| Version | Display | Met Dynamics software product version number. |

| BuildDate | Display | Build date and time of the Met Dynamics Models SysCAD Add-On. |

| License | ||

| File | This is used to locate a Met Dynamics software license file. | |

| Location | Display | Type of Met Dynamics software license or file name and path of license file. |

| SiteCode | Display | Unique machine identifier for license authorisation. |

| ReqdAuth | Display | Authorisation level required, MD-SysCAD Full or MD-SysCAD Runtime. |

| Status | Display | License status, LICENSE_OK indicates a valid license, other messages report licensing errors. |

| IssuedTo | Display | Only visible if Met Dynamics license file is used. Name of organisation/seat the license is authorised to. |

| ExpiryDate | Display | Only visible if Met Dynamics license file is used. License expiry date. |

| DaysLeft | Display | Only visible if Met Dynamics license file is used. Days left before the license expires. |

Additional notes

- Solid species that do not possess a particle size distribution property are split according to the overall mass split of the default particle size distribution species selected in the SysCAD Project Configuration.

- If the default particle size distribution species is not present in the unit feed, the overall split of all other species with particle size distributions combined is used, as determined by the model.

- Gas phase species report directly to the undersize stream without split.

See also

External links

- Met Dynamics - Screen (help.syscad.net)

- Gravity, Dense Medium, and Magnetic Separation Example project (help.syscad.net)