md>Scott.Munro |

imported>Scott.Munro |

| (2 intermediate revisions by 2 users not shown) |

| Line 5: |

Line 5: |

| == Model theory == | | == Model theory == |

|

| |

|

| | {{Restricted content}} |

| | |

| | <hide> |

| [[File:TumblingMillDimensions1.png|thumb|450px|Figure 1. Tumbling mill profile showing the charge shape and lift angle assumptions of the Hogg and Fuerstenau power draw model.]] | | [[File:TumblingMillDimensions1.png|thumb|450px|Figure 1. Tumbling mill profile showing the charge shape and lift angle assumptions of the Hogg and Fuerstenau power draw model.]] |

|

| |

|

| Line 62: |

Line 65: |

| * <math>P_{\rm o}</math> is the power drawn by the overfilling, or excess, slurry component of the mill load (when the interstitial voids are completely filled with slurry (kW). Ball mills only. | | * <math>P_{\rm o}</math> is the power drawn by the overfilling, or excess, slurry component of the mill load (when the interstitial voids are completely filled with slurry (kW). Ball mills only. |

|

| |

|

| <!-- | | <!-- |

| == Additional notes== | | == Additional notes== |

|

| |

|

| Line 79: |

Line 82: |

| Lift angle may alternatively be employed as a 'fitting parameter' for existing power draw measurements and subsequently used to predict power draw under differing conditions, at the user's discretion. | | Lift angle may alternatively be employed as a 'fitting parameter' for existing power draw measurements and subsequently used to predict power draw under differing conditions, at the user's discretion. |

| --> | | --> |

| | </hide> |

|

| |

|

| == Excel == | | == Excel == |

Latest revision as of 07:21, 1 May 2025

Description

This article describes the Hogg and Fuerstenau (1972) method for estimating the power draw of a tumbling mill.[1]

Model theory

This content is available to registered users. Please log in to view. This content is available to registered users. Please log in to view.

|

Excel

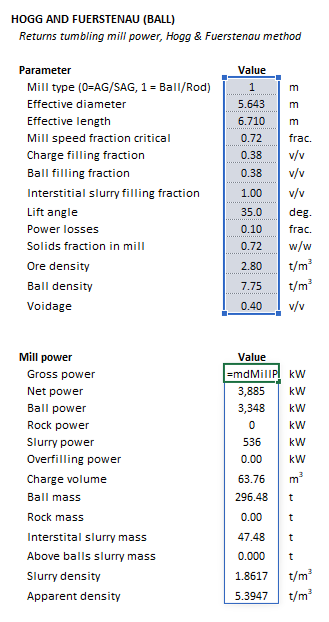

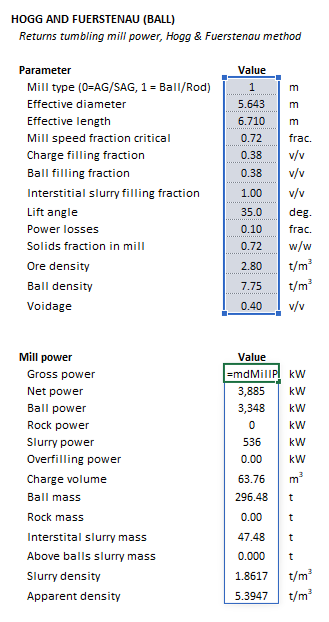

The Hogg and Fuerstenau mill power model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_HoggFuerstenau(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

- [math]\displaystyle{ Parameters=

\begin{bmatrix}

\text{Mill type}\\

D\text{ (m)}\\

L\text{ (m)}\\

N_{\rm c}\text{ (frac)}\\

J\text{ (v/v)}\\

J_{\rm b}\text{ (v/v)}\\

J_{\rm p}\text{ (v/v)}\\

\alpha\text{ (deg.)}\\

(1-\eta)\text{ (kW/kW)}\\

f_{\rm s}\text{ (w/w)}\\

\rho_{\rm m}\text{ (t/m}^{\text{3}}\text{)}\\

\rho_{\rm b}\text{ (t/m}^{\text{3}}\text{)}\\

f_{\rm v}\text{ (v/v)}\\

\end{bmatrix},\;\;\;\;\;\;

mdMillPower\_HoggFuerstenau=

\begin{bmatrix}

P_{\rm gross}\text{ (kw)}\\

P_{\rm net}\text{ (kw)}\\

P_{\rm b}\text{ (kw)}\\

P_{\rm r}\text{ (kw)}\\

P_{\rm s}\text{ (kw)}\\

P_{\rm o}\text{ (kw)}\\

\text{Charge volume (m}^{\text{3}}\text{)}\\

\text{Ball mass (t)}\\

\text{Rock mass (t)}\\

\text{Interstital slurry mass (t)}\\

\text{Above balls slurry mass (t)}\\

\rho_{\rm p}\text{ (t/m}^{\text{3}}\text{)}\\

\rho_{\rm ap}\text{ (t/m}^{\text{3}}\text{)}\\

\end{bmatrix}\;\;\;\;\;\;\;\;\;\;\;\;

}[/math]

where:

- [math]\displaystyle{ \text{Mill type} }[/math] is the type of mill, 0 = autogenous or semi-autogenous, 1 = ball

- [math]\displaystyle{ \text{Charge volume} }[/math] is the volume of the charge (m3)

- [math]\displaystyle{ \text{Ball mass} }[/math] is the mass of balls in the mill (t)

- [math]\displaystyle{ \text{Rock mass} }[/math] is the mass of rocks in the mill (t)

- [math]\displaystyle{ \text{Interstitial slurry mass} }[/math] is the mass of slurry in the interstitial charge void space (t)

- [math]\displaystyle{ \text{Above slurry mass} }[/math] is the mass of excess slurry above the charge (t)

|

Figure 2. Example showing the selection of the Parameters (blue frame), and Results (light blue frame) arrays in Excel. |

Please note the Excel function expects the mill diameter ([math]\displaystyle{ D }[/math]) and length ([math]\displaystyle{ L }[/math]) values in units of meters, which are internally converted to feet for use in the power equation presented above.

SysCAD

The Hogg and Fuerstenau power model is an optional calculation for tumbling mill units. If selected, the input and display parameters below are shown.

| Tag (Long/Short)

|

Input / Display

|

Description/Calculated Variables/Options

|

| HoggFuerstenau

|

| HelpLink

|

|

Opens a link to this page using the system default web browser. Note: Internet access is required.

|

| MillType

|

AG/SAG or Ball/Rod

|

Type of mill, AG/SAG (RockMass, no AboveBallsSLMass) or Ball (AboveBallsSLMass, no RockMass).

|

| MillDiameter

|

Input/Display

|

Diameter of the mill (inside liners).

|

| MillLength

|

Input/Display

|

Length of the mill (inside liners).

|

| FracCS

|

Input/Display

|

Fraction critical speed of the mill.

|

| ChargeFilling

|

Input/Display

|

Volumetric fraction of the mill filled with charge, including balls and interstitial voids between balls.

|

| BallFilling

|

Input/Display

|

Volumetric fraction of the mill filled with balls, including slurry and interstitial voids between balls.

|

| InterstialSLFill

|

Input/Display

|

Volumetric fraction of the interstitial charge void space occupied by slurry.

|

| LiftAngle

|

Input

|

Lift angle of the charge.

|

| PowerLosses

|

Input

|

Fraction of power lost due to mill drive efficiency ([math]\displaystyle{ =1-\eta }[/math]).

|

| SolidsFraction

|

Display

|

Mass fraction of solids in the slurry phase.

|

| OreDensity

|

Display

|

Density of solids.

|

| BallDensity

|

Input/Display

|

Density of balls.

|

| Voidage

|

Input/Display

|

Volumetric fraction of interstitial void space in the charge

|

| ChargeVolume

|

Display

|

Volume of charge in the mill.

|

| BallMass

|

Display

|

Mass of balls in the mill.

|

| RockMass

|

Display

|

Mass of coarse rocks in the mill (AG/SAG only).

|

| InterstitialSLMass

|

Display

|

Mass of slurry occupying charge void space.

|

| AboveBallsSLMass

|

Display

|

Mass of excess slurry resident outside/above charge (Ball mill only).

|

| RhoSlurry

|

Display

|

Density of slurry phase.

|

| ApparentDensity

|

Display

|

Density of total charge (including balls, rock, slurry and voids).

|

| BallsPower

|

Display

|

Power drawn by the ball component of the mill load.

|

| RocksPower

|

Display

|

Power drawn by the rock component of the mill load.

|

| SlurryPower

|

Display

|

Power drawn by the interstitial slurry component of the mill load.

|

| OverfillingPower

|

Display

|

Power drawn by the overfilling, or excess, slurry component of the mill load (when the interstitial voids are completely filled with slurry).

|

| NetPower

|

Display

|

Net power drawn by the mill (excluding drive inefficiencies).

|

| GrossPower

|

Display

|

Gross power drawn by the mill (including drive inefficiencies).

|

See also

References

- ↑ Hogg, R., 1972. Power relationships for tumbling mills. AIME Trans., 252, pp.418-423.