Tumbling Mill (Media Trajectory): Difference between revisions

imported>Scott.Munro m (→SysCAD) |

imported>Scott.Munro m (→Model theory) |

||

| Line 14: | Line 14: | ||

== Model theory == | == Model theory == | ||

{{Restricted content}} | |||

<hide> | |||

[[File:TumblingMillMediaTraj2.png|thumb|625px|Figure 2. Geometric diagram of an outer media element resting on a lifter bar in a tumbling mill at the point of equilibrium (after Powell, 1991).{{Powell (1991)}}]] | [[File:TumblingMillMediaTraj2.png|thumb|625px|Figure 2. Geometric diagram of an outer media element resting on a lifter bar in a tumbling mill at the point of equilibrium (after Powell, 1991).{{Powell (1991)}}]] | ||

| Line 275: | Line 278: | ||

:<math>(v_{x{\rm E}},\, v_{y{\rm E}}) = (v_{x{\rm L}}, \; v_{y{\rm L}} - gt)</math> | :<math>(v_{x{\rm E}},\, v_{y{\rm E}}) = (v_{x{\rm L}}, \; v_{y{\rm L}} - gt)</math> | ||

== Additional notes == | === Additional notes === | ||

{| style="float:right; margin-left: 20px;" | {| style="float:right; margin-left: 20px;" | ||

| Line 282: | Line 285: | ||

|} | |} | ||

=== Friction estimates === | ==== Friction estimates ==== | ||

Powell's (1991) experimental work separately investigated the coefficients of static and kinetic friction between a media element and a lifter bar. The findings suggest: | Powell's (1991) experimental work separately investigated the coefficients of static and kinetic friction between a media element and a lifter bar. The findings suggest: | ||

| Line 292: | Line 295: | ||

Adequate estimates of the coefficients of friction for simulation purposes may be 0 or 0.05 for <math>\mu_{\rm s}</math> and 0.19 for <math>\mu_{\rm k}</math>, but is left to user discretion. | Adequate estimates of the coefficients of friction for simulation purposes may be 0 or 0.05 for <math>\mu_{\rm s}</math> and 0.19 for <math>\mu_{\rm k}</math>, but is left to user discretion. | ||

=== Extracting lifter geometry === | ==== Extracting lifter geometry ==== | ||

Modern mill interior laser scanning devices and/or design drawings provide accurate parametric maps of lifter bar geometry, which may be used to quantify the lifter height (<math>h</math>), lifter width (<math>2y</math>) and lifter face angle (<math>\rho</math>) properties for media trajectory simulation. | Modern mill interior laser scanning devices and/or design drawings provide accurate parametric maps of lifter bar geometry, which may be used to quantify the lifter height (<math>h</math>), lifter width (<math>2y</math>) and lifter face angle (<math>\rho</math>) properties for media trajectory simulation. | ||

| Line 308: | Line 311: | ||

<br> | <br> | ||

<br> | <br> | ||

</hide> | |||

== Excel == | == Excel == | ||

Latest revision as of 11:19, 4 December 2024

Description

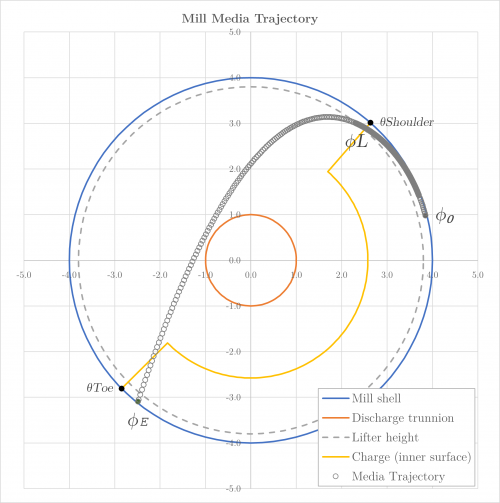

This article describes Powell's (1991) method for predicting the trajectory of the outer media elements in a tumbling mill.[1]

The approach predicts the point of impact of media elements projected into free flight after transit down a lifter bar surface, based on element size, lifter bar geometry, mill diameter and mill rotational speed.

The tumbling mill media trajectory model is particularly useful when combined with an estimate of charge position (e.g. Morrell's method), which allows analyses such as:

- Identifying and mitigating the risks of shell liner damage from media impact through lifter bar (or mill) design

- Monitoring trajectory and point of impact changes with charge level, mill speed or liner and lifter bar wear in operational mills

- Limiting the maximum operating speed (and hence power and throughput) in a mill simulation or process control sub-systems

Model theory

Excel

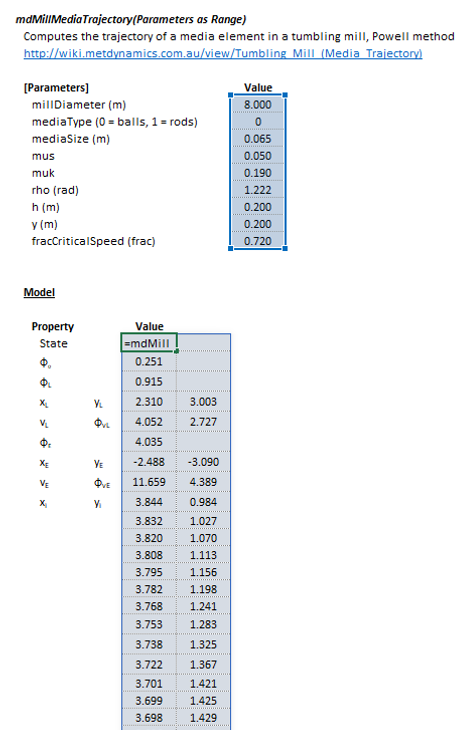

The tumbling mill media trajectory model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_MillMediaTrajectory(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

|

and:

|

SysCAD

The media trajectory model is an optional calculation for tumbling mill units. If selected, the input and display parameters below are shown.

See also

References

- ↑ Powell, M.S., 1991. The effect of liner design on the motion of the outer grinding elements in a rotary mill. International Journal of Mineral Processing, 31(3-4), pp.163-193.