Stirred Mill (Power, Nitta): Difference between revisions

md>Scott.Munro m (Text replacement - "\rho_{p}" to "\rho_{\rm p}") |

imported>Scott.Munro m (→See also) |

||

| (One intermediate revision by one other user not shown) | |||

| Line 199: | Line 199: | ||

== See also == | == See also == | ||

* [[Mill (Herbst-Fuerstenau)]] | * [[Mill (Herbst-Fuerstenau)]] | ||

* [[ | * [[Stirred Mill (Perfect Mixing)]] | ||

* [[ | * [[Stirred Mill (Perfect Mixing, Dynamic)]] | ||

== References == | == References == | ||

Latest revision as of 02:30, 29 February 2024

Description

This article describes the Nitta method for estimating the power draw of a vertical stirred mill.[1]

Model theory

The Nitta approach computes mill power as:

where:

- is the net power draw of the mill, i.e. excluding mill drive losses (kW)

- is the gross power draw of the mill, i.e. including mill drive losses (kW)

- is the mill drive efficiency (kW/kW)

- is the power constant (kW), suggested.

- is mill height (m)

- is the fraction of mill volume occupied by the media charge, void space and stirrer below the charge level (v/v).

- is the fraction of mill volume occupied by the stirrer below the level of the media charge (v/v).

- is the diameter of the stirrer (m)

- is the gap between the inside wall of the mill and the stirrer (m)

- is the rotational speed of the stirrer (rps)

Adopting a similar approach as the Hogg and Fuerstenau tumbling mill power model, the net power draw, , may be separated into its contributing constituents:

where:

- is the power drawn by the ball component of the mill load (kW)

- is the power drawn by the interstitial slurry component of the mill load (kW)

- is the volumetric fraction of interstitial void space in the charge (usually 0.4) (v/v)

- is the density of balls (t/m3)

The apparent charge density, , may be computed as:

where is the density of slurry (t/m3).

The slurry density, , may be computed as:

where is the mass fraction of solids in the slurry (w/w), and is the densityy of solid ore particles (t/m3).

Additional notes

The Nitta model does not include a term for charge density, which may compromise its ability to predict mill power draw with alternative grinding media materials, ore densities or feed solids fractions.

Excel

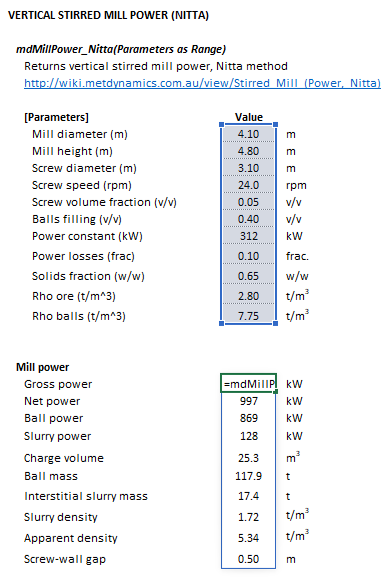

The Nitta mill power model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_Nitta(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

|

|

SysCAD

The Nitta power model is an optional calculation for stirred mill units. If selected, the input and display parameters below are shown.

See also

References

- ↑ Nitta, S., Furuyama, T., Bissombolo, A. and Mori, S., 2006, September. Estimation of the motor power of the tower mill through dimensional analysis. In Proceedings of 23rd International Mineral Processing Congress (pp. 3-8).

![{\displaystyle P_{\rm {net}}=\eta P_{\rm {gross}}=K\cdot \left[H(J_{\rm {b}}-J_{\rm {s}})\right]^{0.884}S^{2.232}D_{\rm {G}}N^{1.232}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/517e19aa362882937b338d43b54867a16b20af63)