Revision as of 11:06, 16 May 2023 by md>Scott.Munro

Description

This article describes the Heath (Heath et al. 2017) method for estimating the power draw of a High Intensity Grinding (HIG) stirred mill.[1]

Model theory

This section is currently under construction. Please check back later for updates and revisions. This section is currently under construction. Please check back later for updates and revisions.

|

Excel

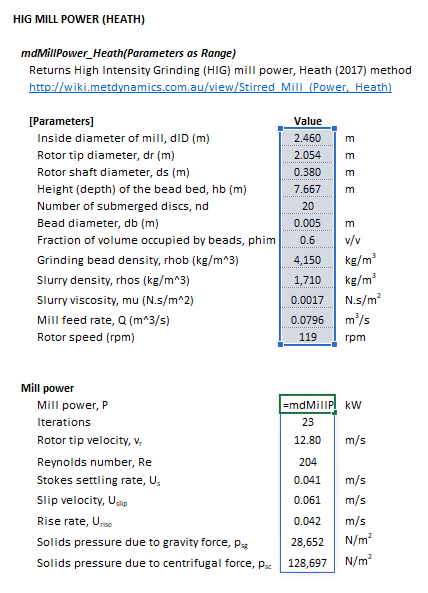

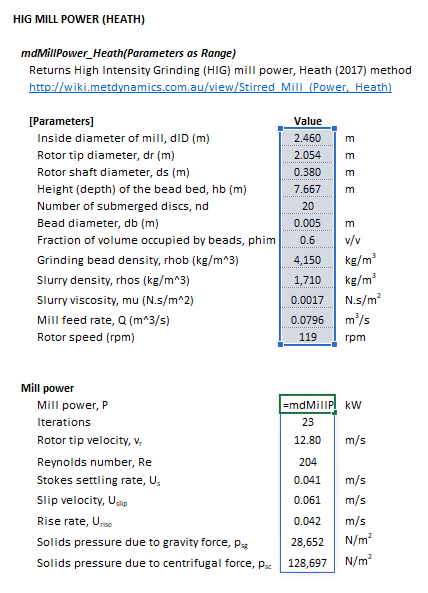

The Heath HIG stirred mill power model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_Heath(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

where:

is the internal diameter of the mill (m) is the internal diameter of the mill (m) is the rotor tip diameter (m) is the rotor tip diameter (m) is the rotor shaft diameter (m) is the rotor shaft diameter (m) is the height of the bead bed (m) is the height of the bead bed (m) is the number of submerged discs is the number of submerged discs is the bead diameter (m) is the bead diameter (m) is the fraction of mill volume occupied by beads (v/v) is the fraction of mill volume occupied by beads (v/v) is the density of the grinding beads (t/m3) is the density of the grinding beads (t/m3) is the density of slurry (t/m3) is the density of slurry (t/m3) is the slurry viscosity (N.s/m2) is the slurry viscosity (N.s/m2) is the volumetric flow rate of slurry feed to the mill (m3/s) is the volumetric flow rate of slurry feed to the mill (m3/s) is the rotational speed of the rotor (rpm) is the rotational speed of the rotor (rpm) is mill power (kW) is mill power (kW) is the number of internal iterations is the number of internal iterations is the rotor tip velocity (m/s) is the rotor tip velocity (m/s) is the Reynolds Number is the Reynolds Number is the Stokes settling rate (m/s) is the Stokes settling rate (m/s) is is the slip velocity (m/s) is is the slip velocity (m/s) is the rise velocity (m/s) is the rise velocity (m/s) is the solids pressure due to gravity (N/m2) is the solids pressure due to gravity (N/m2) is the solids pressure due to centrifugal force (N/m2) is the solids pressure due to centrifugal force (N/m2)

|

Figure 1. Example showing the selection of the Parameters (blue frame), and Results (light blue frame) arrays in Excel. |

SysCAD

This section is currently under construction. Please check back later for updates and revisions. This section is currently under construction. Please check back later for updates and revisions.

|

References

- ↑ Heath, A., Keikkala, V., Paz, A. and Lehto, H., 2017. A power model for fine grinding HIGmills with castellated rotors. Minerals Engineering, 103, pp.25-32.