Stirred Mill (Power, Heath): Difference between revisions

Jump to navigation

Jump to search

imported>Scott.Munro m (→SysCAD) |

imported>Scott.Munro m (→Model theory) |

||

| Line 5: | Line 5: | ||

== Model theory == | == Model theory == | ||

{{Restricted content}} | |||

<hide> | |||

Heath et al. (2017) proposed the following relationship for the power draw, <math>P</math> (kW), of a HIGmill with castellated rotors:{{Heath et al. (2017)}} | Heath et al. (2017) proposed the following relationship for the power draw, <math>P</math> (kW), of a HIGmill with castellated rotors:{{Heath et al. (2017)}} | ||

| Line 90: | Line 93: | ||

Furthermore, the coefficient <math>k_1</math> appears twice, in both the equations for <math>P</math> and <math>p_{\rm s,c}</math>.{{Heath et al. (2017)}} The <math>p_{\rm s,c}</math> term itself also appears in <math>P</math> and is adjusted by <math>k_4</math>, making the <math>k_1</math> repetition unusual, and somewhat redundant. It is probable that the presence of <math>k_1</math> in the equation for <math>p_{\rm s,c}</math> is also a printing error and should be omitted. This is supported by application of the power model to industrial HIGmill specifications, which produces an appropriate result only with the equations as presented above. | Furthermore, the coefficient <math>k_1</math> appears twice, in both the equations for <math>P</math> and <math>p_{\rm s,c}</math>.{{Heath et al. (2017)}} The <math>p_{\rm s,c}</math> term itself also appears in <math>P</math> and is adjusted by <math>k_4</math>, making the <math>k_1</math> repetition unusual, and somewhat redundant. It is probable that the presence of <math>k_1</math> in the equation for <math>p_{\rm s,c}</math> is also a printing error and should be omitted. This is supported by application of the power model to industrial HIGmill specifications, which produces an appropriate result only with the equations as presented above. | ||

</hide> | |||

== Excel == | == Excel == | ||

Revision as of 11:22, 4 December 2024

Description

This article describes the Heath et al. (2017) method for estimating the power draw of a castellated rotor High Intensity Grinding stirred mill (HIGmill).[1]

Model theory

Excel

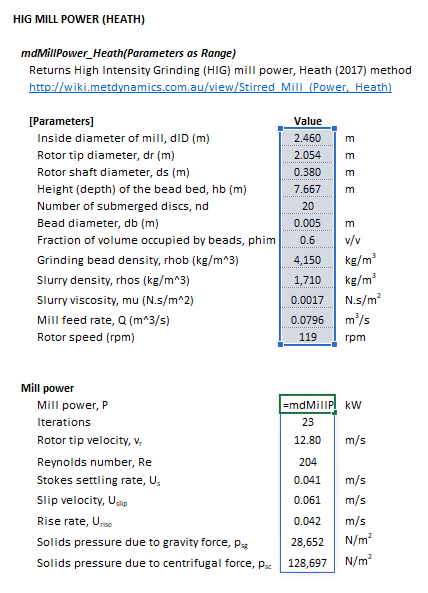

The Heath HIG stirred mill power model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_Heath(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

|

where:

|

SysCAD

The Heath power model is an optional calculation for stirred mill units. If selected, the input and display parameters below are shown.

References

- ↑ Heath, A., Keikkala, V., Paz, A. and Lehto, H., 2017. A power model for fine grinding HIGmills with castellated rotors. Minerals Engineering, 103, pp.25-32.