Stirred Mill (Power, Heath): Difference between revisions

Jump to navigation

Jump to search

md>Scott.Munro m (→Excel) |

imported>Scott.Munro m (→Model theory) |

||

| (3 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

== Description == | == Description == | ||

This article describes the | This article describes the Heath et al. (2017) method for estimating the power draw of a castellated rotor High Intensity Grinding stirred mill (HIGmill).{{Heath et al. (2017)}} | ||

== Model theory == | == Model theory == | ||

{{ | {{Restricted content}} | ||

<hide> | |||

Heath et al. (2017) proposed the following relationship for the power draw, <math>P</math> (kW), of a HIGmill with castellated rotors:{{Heath et al. (2017)}} | |||

:<math>P = k_1 \cdot n_{\rm d} {d_{\rm r}}^{k_2} {v_t}^{k_3} ( p_{\rm s,g} + k_4 p_{\rm s,c})</math> | |||

where: | |||

* <math>n_{\rm d}</math> is the number of submerged discs | |||

* <math>d_{\rm r}</math> is the rotor tip diameter (m) | |||

* <math>v_{\rm t}</math> is the rotor tip velocity (m/s) | |||

* <math>p_{\rm s,g}</math> is the solids pressure due to gravity (N/m<sup>2</sup>) | |||

* <math>p_{\rm s,c}</math> is the solids pressure due to centrifugal force (N/m<sup>2</sup>) | |||

and <math>k_1-k_4</math> have the values shown in Table 1. | |||

:{| class="wikitable" | |||

|+ Coefficients and exponents of the Heath et al. power equation.{{Heath et al. (2017)}} | |||

|- | |||

! Coefficient or exponent !! Value | |||

|- | |||

| <math>k_1</math>|| 0.000197 | |||

|- | |||

| <math>k_2</math>|| 1.3 | |||

|- | |||

| <math>k_3</math>|| 0.8 | |||

|- | |||

| <math>k_4</math>|| 0.15 | |||

|} | |||

The solids pressure due to centrifugal force, <math>\rho_{\rm s,c}</math> (N/m<sup>2</sup>), is: | |||

:<math>p_{\rm s,c} = \frac{4}{3} \pi^2 \omega^2 \left (\rho_{\rm b} - \rho_{\rm s} \right ) \left ({r_{\rm rotor}}^2 - {r_{\rm shaft}}^2 \right )</math> | |||

where: | |||

* <math>\omega</math> is the rotation rate of the rotor (rps) | |||

* <math>\rho_{\rm b}</math> is the density of the grinding beads (t/m<sup>3</sup>) | |||

* <math>\rho_{\rm s}</math> is the density of slurry (t/m<sup>3</sup>) | |||

* <math>r_{\rm rotor}</math> is the rotor tip radius (m), i.e <math>0.5d_{\rm r}</math> | |||

* <math>r_{\rm shaft}</math> is the rotor shaft radius (m) | |||

The solids pressure due to gravity, <math>\rho_{\rm s,g}</math> (N/m<sup>2</sup>), is: | |||

:<math>p_{\rm s,g} = | |||

\begin{cases} | |||

0.5 g h_{\rm b} \left (\rho_{\rm b} - \rho_{\rm s} \right ) \left ( 1 - \dfrac{U_{\rm slip}}{U_{\rm rise}} \right ) & U_{\rm slip} < U_{\rm rise}\\ | |||

0 & U_{\rm slip} \geq U_{\rm rise}\\ | |||

\end{cases} | |||

</math> | |||

where: | |||

* <math>h_{\rm b}</math> is the height of the bead bed (m) | |||

* <math>U_{\rm slip}</math> is is the slip velocity (m/s) | |||

* <math>U_{\rm rise}</math> is the rise velocity (m/s) | |||

* <math>g</math> is acceleration due to gravity (m/s<sup>2</sup>) | |||

The rise velocity, <math>U_{\rm rise}</math> (m/s) is: | |||

:<math>U_{\rm rise} = \dfrac{Q}{\pi \left ( \dfrac{d_{\rm ID}}{2} \right )^2 (1 - \phi_{\rm m})}</math> | |||

where: | |||

* <math>Q</math> is the volumetric flow rate of slurry feed to the mill (m<sup>3</sup>/s) | |||

* <math>d_{\rm ID}</math> is the internal diameter of the mill (m) | |||

* <math>\phi_{\rm m}</math> is the fraction of the charge volume (i.e. bead bed) occupied by beads (v/v) | |||

The slip velocity, <math>U_{\rm slip}</math> (m/s) is: | |||

:<math>U_{\rm slip} = \dfrac{U_{\rm s} \phi_{\rm m}}{1 - \phi_{\rm m}}</math> | |||

The Stokes settling rate, <math>U_{\rm slip}</math> (m/s), is determined from: | |||

:<math>U_{\rm s} = \dfrac{ {d_{\rm b}}^2 g (\rho_{\rm b} - \rho_{\rm s} ) (1 - \phi_{\rm m})^{4.65} }{18 \mu \left ( 1 + 0.15 \mathrm{Re}^{0.687} \right )}</math> | |||

and | |||

:<math>\mathrm{Re} = \dfrac{ d_{\rm b} \rho_{\rm s} U_{\rm s}}{\mu}</math> | |||

where: | |||

* <math>d_{\rm b}</math> is the bead diameter (m) | |||

* <math>\mu</math> is the slurry viscosity (N.s/m<sup>2</sup>) | |||

The Reynolds number, <math>\mathrm{Re}</math>, requires the settling velocity, <math>U_{\rm s}</math>, which itself requires the Reynolds number. Therefore an iterating numerical solution is necessary to resolve the slip velocity. | |||

</hide><div class="user-show"> | |||

=== Additional notes === | |||

</div><hide> | |||

The Heath et al. (2017) publication appears to contain a printing error, where the value of coefficient <math>k_4</math> is inadvertently referred to as <math>k_2</math>.{{Heath et al. (2017)}} | |||

Furthermore, the coefficient <math>k_1</math> appears twice, in both the equations for <math>P</math> and <math>p_{\rm s,c}</math>.{{Heath et al. (2017)}} The <math>p_{\rm s,c}</math> term itself also appears in <math>P</math> and is adjusted by <math>k_4</math>, making the <math>k_1</math> repetition unusual, and somewhat redundant. It is probable that the presence of <math>k_1</math> in the equation for <math>p_{\rm s,c}</math> is also a printing error and should be omitted. This is supported by application of the power model to industrial HIGmill specifications, which produces an appropriate result only with the equations as presented above. | |||

</hide> | |||

== Excel == | == Excel == | ||

| Line 28: | Line 118: | ||

n_{\rm d}\\ | n_{\rm d}\\ | ||

d_{\rm b}\text{ (m)}\\ | d_{\rm b}\text{ (m)}\\ | ||

\ | \phi_{\rm m}\text{ (v/v)}\\ | ||

\rho_{\rm b}\text{ (t/m}^3\text{)}\\ | \rho_{\rm b}\text{ (t/m}^3\text{)}\\ | ||

\rho_{\rm s}\text{ (t/m}^3\text{)}\\ | \rho_{\rm s}\text{ (t/m}^3\text{)}\\ | ||

| Line 40: | Line 130: | ||

P\text{ (kW)}\\ | P\text{ (kW)}\\ | ||

\text{Iterations}\\ | \text{Iterations}\\ | ||

v_{\rm | v_{\rm t}\text{ (m/s)}\\ | ||

\text{Re}\\ | \text{Re}\\ | ||

U_{\rm s}\text{ (m/s)}\\ | U_{\rm s}\text{ (m/s)}\\ | ||

U_{\rm slip}\text{ (m/s)}\\ | U_{\rm slip}\text{ (m/s)}\\ | ||

U_{\rm rise}\text{ (m/s)}\\ | U_{\rm rise}\text{ (m/s)}\\ | ||

p_{\rm s,g}\text{ (N/m}^2\text{)}\\ | |||

p_{\rm s,c}\text{ (N/m}^2\text{)}\\ | |||

\end{bmatrix}\;\;\;\;\;\;\;\;\;\;\;\; | \end{bmatrix}\;\;\;\;\;\;\;\;\;\;\;\; | ||

</math> | </math> | ||

where: | where: | ||

* <math> | * <math>N_{\rm r}</math> is the rotational speed of the rotor (rpm), i.e. <math>\omega \times 60</math> | ||

* <math>d_{\rm s}</math> is the rotor shaft diameter (m), i.e. <math>2 r_{\rm rotor}</math> | |||

* <math>d_{\rm s}</math> is the rotor shaft diameter (m) | |||

* <math>\text{Iterations}</math> is the number of internal iterations | * <math>\text{Iterations}</math> is the number of internal iterations | ||

| [[File:StirredMillPowerHeath1.png|left|frame|Figure 1. Example showing the selection of the '''Parameters''' (blue frame), and '''Results''' (light blue frame) arrays in Excel.]] | | [[File:StirredMillPowerHeath1.png|left|frame|Figure 1. Example showing the selection of the '''Parameters''' (blue frame), and '''Results''' (light blue frame) arrays in Excel.]] | ||

| Line 79: | Line 150: | ||

== SysCAD == | == SysCAD == | ||

{{ | The Heath power model is an optional calculation for stirred mill units. If selected, the input and display parameters below are shown. | ||

{{SysCAD (Text, Table Header)}} | |||

|- | |||

! colspan="3" style="text-align:left;" |''Heath'' | |||

{{SysCAD (Text, Help Link)}} | |||

|- | |||

|MillDiameter | |||

|style="background: #eaecf0" | Input/Display | |||

|Inside diameter of the mill. | |||

|- | |||

|RotorTipDiameter | |||

|style="background: #eaecf0" | Input/Display | |||

|Diameter of the rotor at the tip. | |||

|- | |||

|RotorShaftDiameter | |||

|Input | |||

|Diameter of the rotor shaft. | |||

|- | |||

|MediaBedHeight | |||

|style="background: #eaecf0" | Input/Display | |||

|Height of the media (bead) bed. | |||

|- | |||

|NumSubmergedDiscs | |||

|Input | |||

|Number of submerged discs. | |||

|- | |||

|MediaDiameter | |||

|style="background: #eaecf0" | Input/Display | |||

|Diameter of the media (beads). | |||

|- | |||

|MediaVolFrac | |||

|Input | |||

|Volume fraction of media solids in the charge/bed. | |||

|- | |||

|MediaDensity | |||

|Input | |||

|Density of media. | |||

|- | |||

|SlurryDensity | |||

|style="background: #eaecf0" | Display | |||

|Density of slurry in the feed (or load for Dynamic). | |||

|- | |||

|SlurryViscosity | |||

|Input | |||

|Dynamic viscosity of slurry. | |||

|- | |||

|Feed.SLVolFlow / Feed.SLQv | |||

|style="background: #eaecf0" | Display | |||

|Volumetric flow rate of slurry into the mill. | |||

|- | |||

|RotorSpeed | |||

|style="background: #eaecf0" | Input/Display | |||

|Rotational speed of the rotor. | |||

|- | |||

|Iterations | |||

|style="background: #eaecf0" | Display | |||

|Number of internal iterations required to solve settling velocity equations. | |||

|- | |||

|RotorTipVelocity | |||

|style="background: #eaecf0" | Display | |||

|Velocity of the rotor at the tip. | |||

|- | |||

|ReynoldsNumber / Re | |||

|style="background: #eaecf0" | Display | |||

|Reynolds number. | |||

|- | |||

|SettlingVelocity / Us | |||

|style="background: #eaecf0" | Display | |||

|Stokes settling velocity. | |||

|- | |||

|SlipVelocity / Uslip | |||

|style="background: #eaecf0" | Display | |||

|Fluid slip velocity. | |||

|- | |||

|RiseVelocity / Urise | |||

|style="background: #eaecf0" | Display | |||

|Fluid rise velocity. | |||

|- | |||

|GravityPressure / psg | |||

|style="background: #eaecf0" | Display | |||

|Pressure due to gravitational force. | |||

|- | |||

|CentrifugalPressure / psc | |||

|style="background: #eaecf0" | Display | |||

|Pressure due to centrifugal force. | |||

|- | |||

|GrossPower | |||

|style="background: #eaecf0" | Display | |||

|Gross power drawn by the mill. | |||

|} | |||

== References == | == References == | ||

Latest revision as of 07:11, 1 May 2025

Description

This article describes the Heath et al. (2017) method for estimating the power draw of a castellated rotor High Intensity Grinding stirred mill (HIGmill).[1]

Model theory

Additional notes

Excel

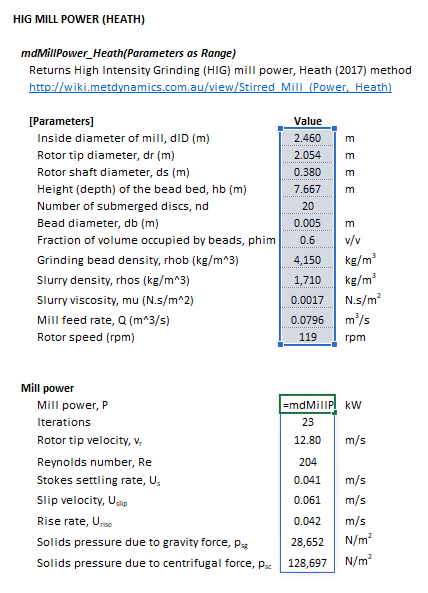

The Heath HIG stirred mill power model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_Heath(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

|

where:

|

SysCAD

The Heath power model is an optional calculation for stirred mill units. If selected, the input and display parameters below are shown.

References

- ↑ Heath, A., Keikkala, V., Paz, A. and Lehto, H., 2017. A power model for fine grinding HIGmills with castellated rotors. Minerals Engineering, 103, pp.25-32.