Comminution Circuit Specific Energy (Bond): Difference between revisions

Jump to navigation

Jump to search

Scott Munro (talk | contribs) m (1 revision imported) |

imported>Scott.Munro m (→Excel) |

||

| Line 22: | Line 22: | ||

:<math>Parameters= | :<math>Parameters= | ||

\begin{bmatrix} | \begin{bmatrix} | ||

\ | {\rm WI}\text{ (kWh/t)}\\ | ||

F_{80}\text{ (}\rm{\mu}\text{m)}\\ | F_{80}\text{ (}\rm{\mu}\text{m)}\\ | ||

P_{80}\text{ (}\rm{\mu}\text{m)}\\ | P_{80}\text{ (}\rm{\mu}\text{m)}\\ | ||

| Line 38: | Line 38: | ||

\begin{bmatrix} | \begin{bmatrix} | ||

W\text{ (kWh/t)}\\ | W\text{ (kWh/t)}\\ | ||

\ | {\rm EF1}\\ | ||

\ | {\rm EF2}\\ | ||

\ | {\rm EF3}\\ | ||

\ | {\rm EF4}\\ | ||

\ | {\rm EF5}\\ | ||

\ | {\rm EF6}\\ | ||

\ | {\rm EF7}\\ | ||

\ | {\rm EF8}\\ | ||

\end{bmatrix}\;\;\;\;\;\;\;\;\;\;\;\; | \end{bmatrix}\;\;\;\;\;\;\;\;\;\;\;\; | ||

</math> | </math> | ||

where: | where: | ||

* <math>\ | * <math>{\rm WI}\text{ (kWh/t)}</math> is the Bond Work Index of the ore being processed (kWh/t) | ||

* <math>F_{80}\text{ (}\rm{\mu}\text{m)}</math> is the 80% fraction passing size of the feed (µm) | * <math>F_{80}\text{ (}\rm{\mu}\text{m)}</math> is the 80% fraction passing size of the feed (µm) | ||

* <math>P_{80}\text{ (}\rm{\mu}\text{m)}</math> is the 80% fraction passing size of the product (µm) | * <math>P_{80}\text{ (}\rm{\mu}\text{m)}</math> is the 80% fraction passing size of the product (µm) | ||

| Line 62: | Line 62: | ||

* <math>\text{Closed circuit crushing}</math> indicates if the feed is prepared with closed circuit crushing | * <math>\text{Closed circuit crushing}</math> indicates if the feed is prepared with closed circuit crushing | ||

* <math>W</math> is the operating work index (kWh/t) | * <math>W</math> is the operating work index (kWh/t) | ||

* <math>\ | * <math>{\rm EF}1-{\rm EF}8</math> are efficiency factors applied to the calculation of operating work index. | ||

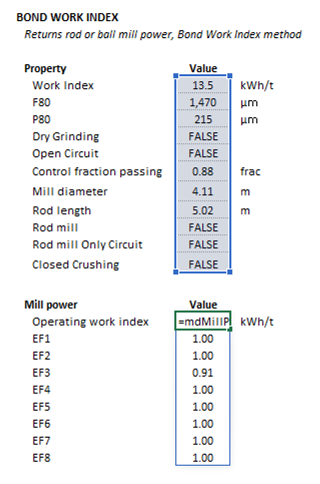

| [[File:BondWI1.png|left|frame|Figure 1. Example showing the selection of the '''Parameters''' (blue frame), and '''Results''' (light blue frame) arrays in Excel.]] | | [[File:BondWI1.png|left|frame|Figure 1. Example showing the selection of the '''Parameters''' (blue frame), and '''Results''' (light blue frame) arrays in Excel.]] | ||

Latest revision as of 12:01, 29 July 2023

Description

This article describes the Bond method for estimating the specific energy of comminution circuits.[1]

Model theory

Excel

The Bond specific energy model may be invoked from the Excel formula bar with the following function call:

=mdMillPower_BondWI(Parameters as Range)

Invoking the function with no arguments will print Help text associated with the model, including a link to this page.

The Parameters array and model results are defined below in matrix notation, along with an example image showing the selection of the same arrays in the Excel interface:

|

where:

|

See also

References

- ↑ Rowland, C.A., 2006. 'Bond’s method for selection of ball mills', in Kawatra, S.K. (ed.) Advances in Comminution. Society for Mining, Metallurgy, and Exploration, Inc., pp.385-397.